Titanium alloy cylinder lock type folding system hot isostatic pressure forming method

A folding system and hot isostatic pressing technology, applied in the field of aerospace manufacturing, can solve the problems of difficult control of product performance, complex structure, complex casting process, etc., and achieve the effect of reducing post-processing, improving structural strength, and shortening processing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The hot isostatic pressing forming method of the titanium alloy cylindrical lock folding system provided by the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0026] Such as figure 1 — Figure 5 As shown, the titanium alloy cylindrical lock folding system hot isostatic pressing method provided by the invention includes

[0027] The following steps in order:

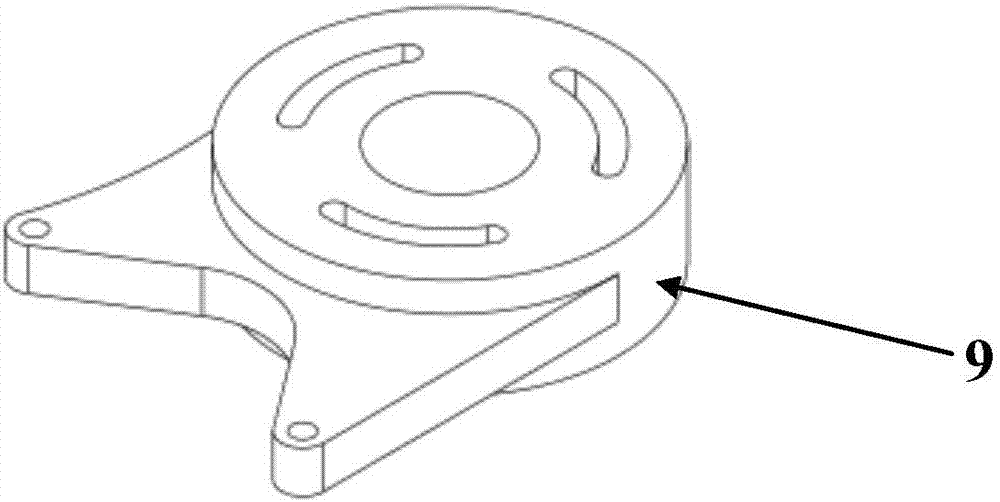

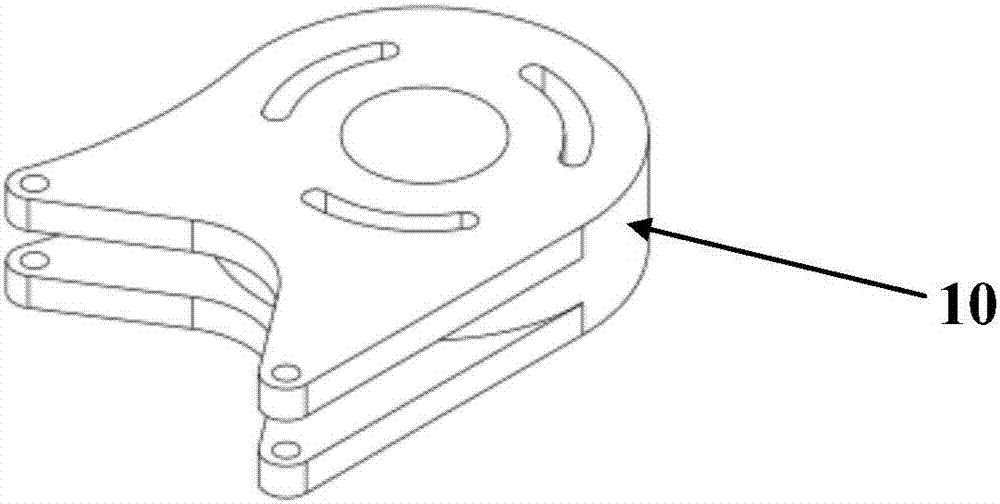

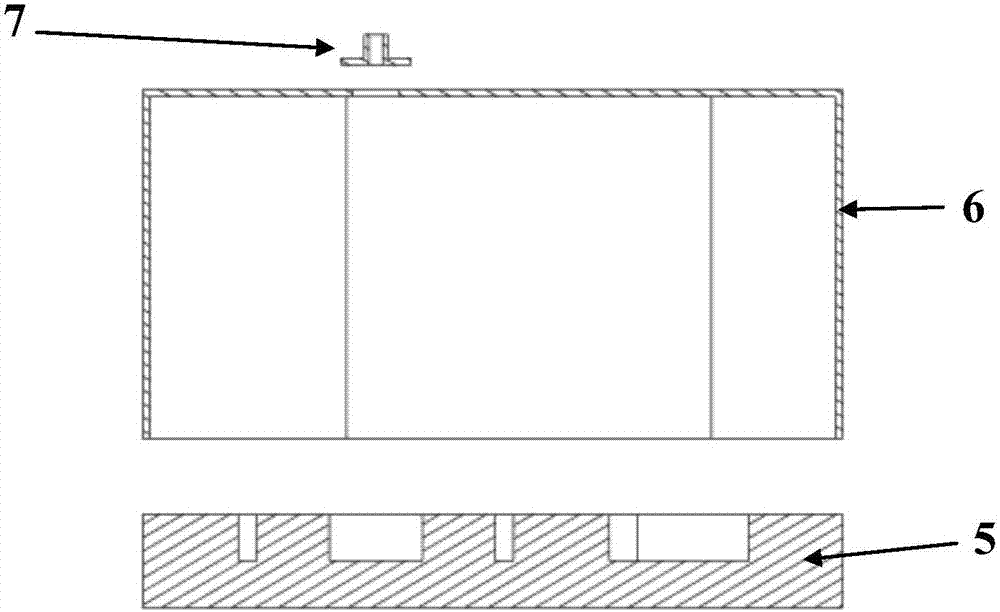

[0028] 1) According to the structural characteristics of titanium alloy parts 9 and 10, such as Figure 4 Inner mold 1 , inner mold 2 , fixed upper plate 3 and outer core 4 are shown. The material of the internal mold is nickel-based superalloy GH4169, and the material of the external core is 45# steel. The internal mold and the external core are embedded in the bottom plate by manual grinding. The processing and manufacturing of the internal mold is processed by a lathe, and the surface is polished to make the surface smooth.

[0029...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com