Method for manufacturing thyratron transistor door-pole and cathode isolation

A manufacturing method and thyristor technology, which are applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as troublesome operation, chip cracking, adding two molybdenum sheet bonding processes, etc., and achieve the effect of preventing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

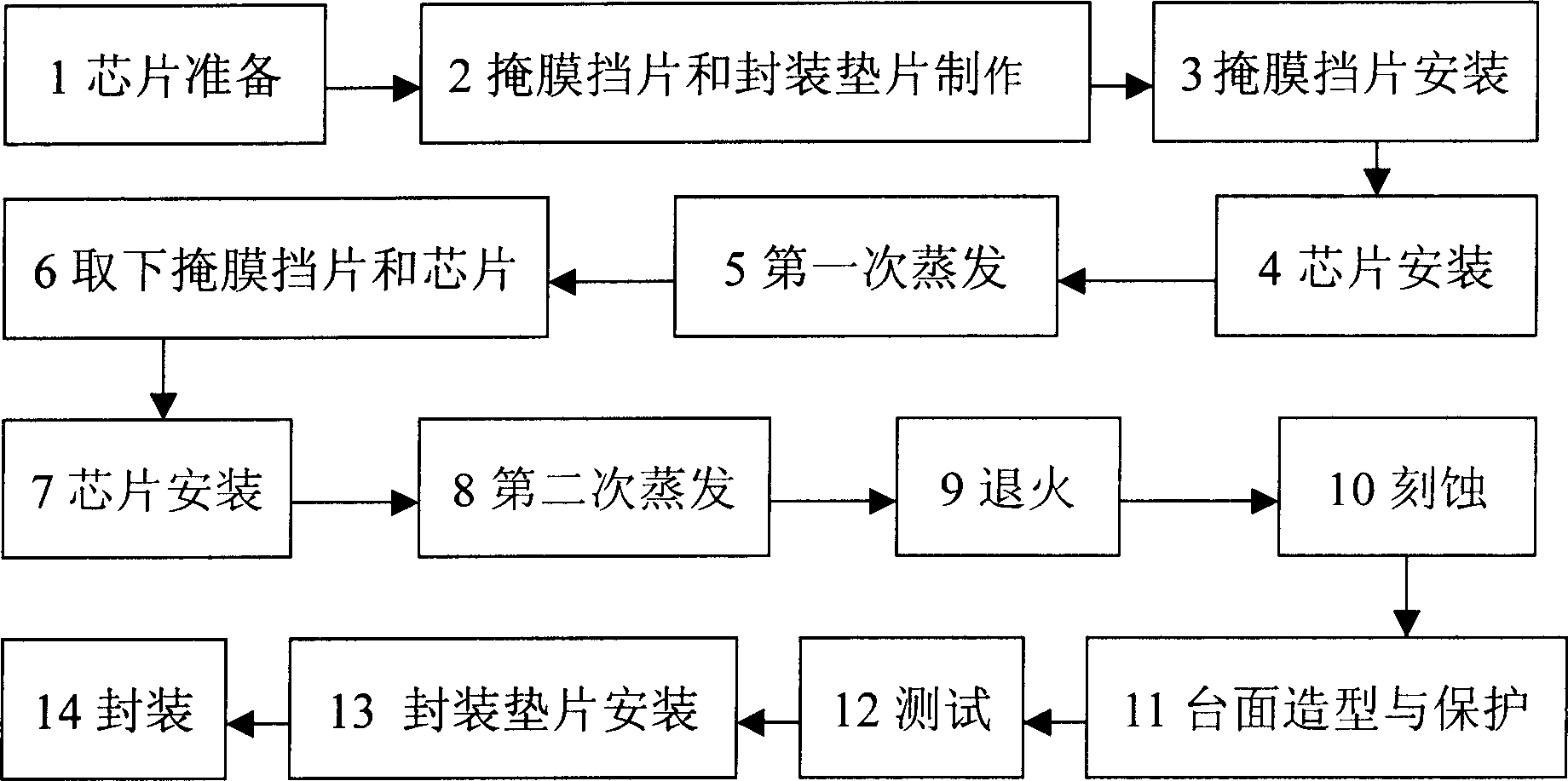

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

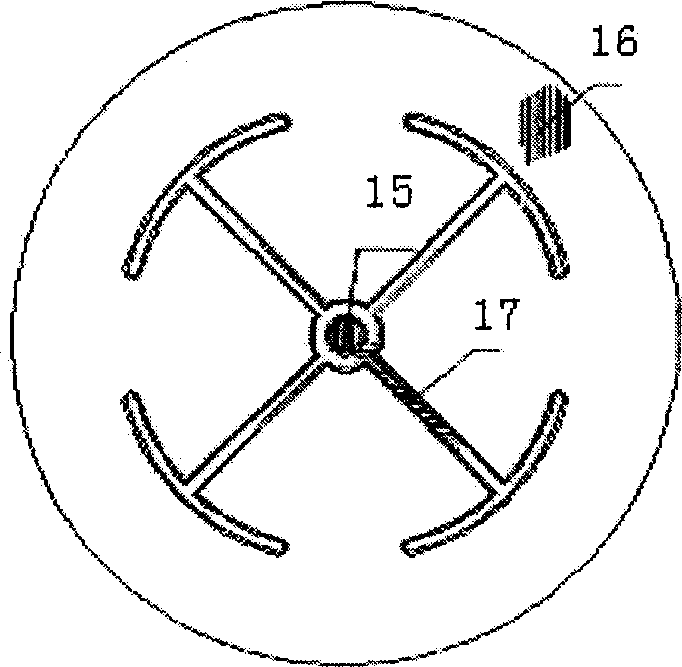

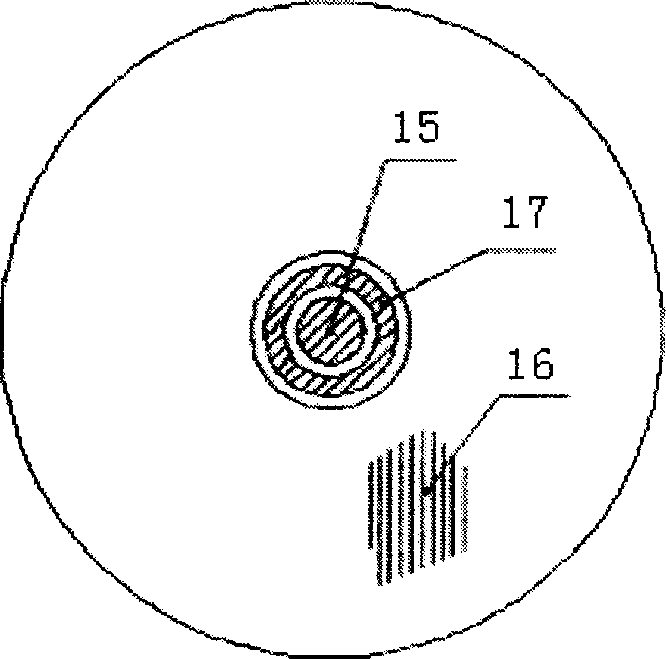

[0014] Such as figure 2 , 3 As shown, in the structure of the thyristor, the gate 15 is generally arranged in the center of the device to facilitate the extraction of the gate 15, wherein the amplifying gate 17 is suspended, and the cathode 16 is in the outermost layer. With the development of thyristors in the direction of high current and high voltage, in order to improve the dynamic characteristics of thyristor devices, it is sometimes necessary to use figure 2 Similar complex gate cathode structure. In the packaging process, in order to avoid the short circuit between the amplification gate 17 and the cathode 16 and to facilitate packaging, the conventional method is to paste a piece of conductive sheet on the cathode 16 surface with a pattern close to the cathode surface. The method of the present invention is exactly by adopting means such as mask,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com