Double-mold-embedment production process of instrument panel

A production process and technology for instrument panels, which are applied in the field of double-embedded mold production of instrument panels, can solve problems such as increased cost, deformation, and high cost of the whole set, and achieve the effect of saving production costs and less equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

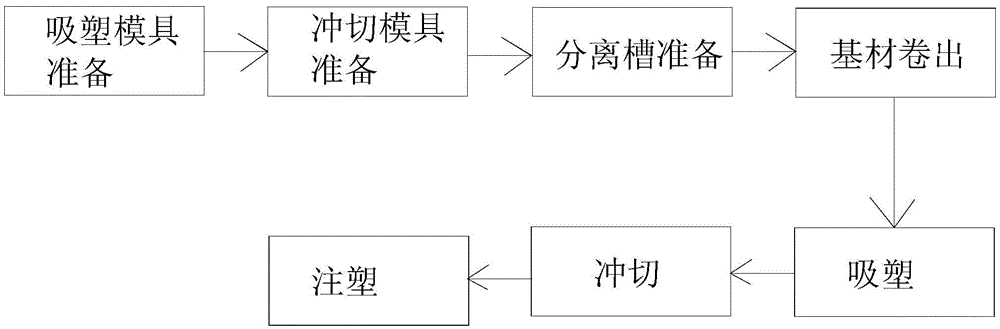

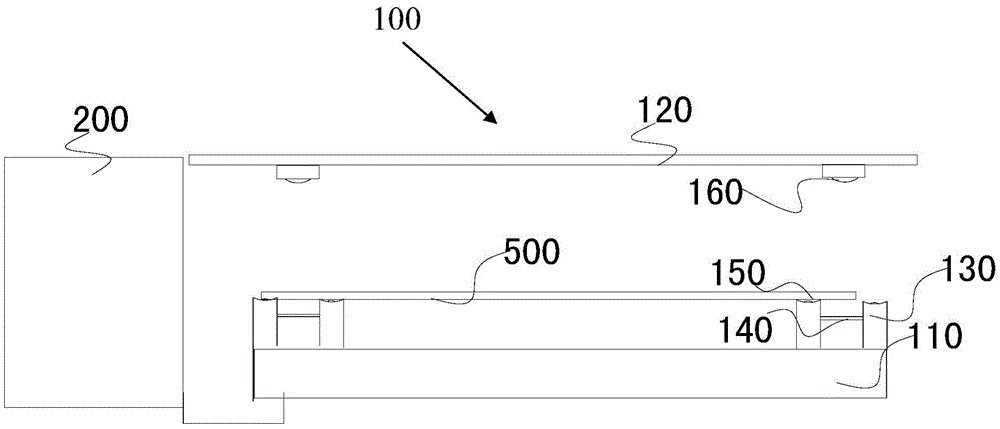

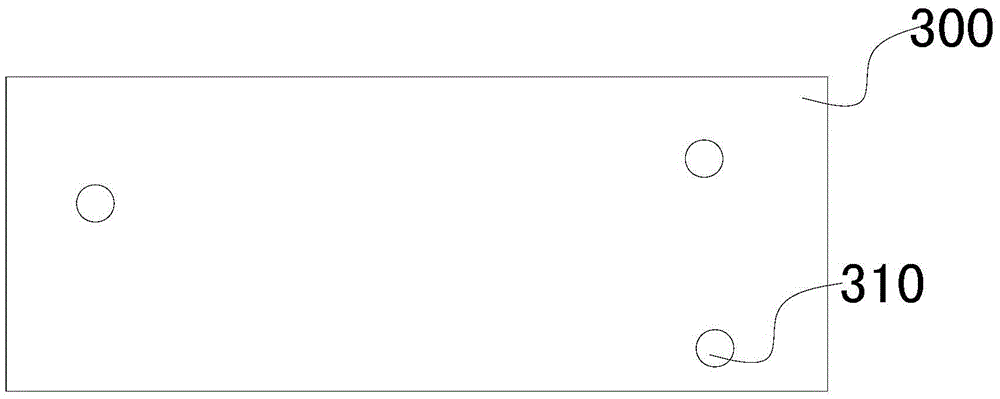

[0029] figure 1 It is a process flow diagram of the present invention. figure 2 It is the structural diagram of the plastic mold. image 3 Structural diagram of the fixed plate. Figure 4 It is a fixed sketch in the injection molding process. Figure 5 It is a schematic diagram of the displacement problem that occurs in the injection molding process. Figure 6 Structural diagram of the separation tank.

[0030] Such as figure 1 As shown, a double insert mold production process for an instrument panel, its process flow is as follows:

[0031] Blister mold preparation, punching die preparation, split tank preparation, substrate roll out, blister, die cutting and injection molding.

[0032] Such as figure 2 As shown, the preparation of the plastic mold includes the design of the plastic mold and the installation and debugging of the temperature control equipment 200 of the plastic mold. Rubber ring 140, groove metal point 150 and pressure plate metal point 160, plastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com