Production process of rubber diaphragm of automobile brake chamber

A production process and technology of rubber diaphragm, which is applied in the field of production process of automobile brake air chamber rubber diaphragm, can solve the problems of low production efficiency, large amount of diaphragm cloth, and high manufacturing cost, so as to achieve low production cost and solve offset And Lubu, improve the pass rate and product performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

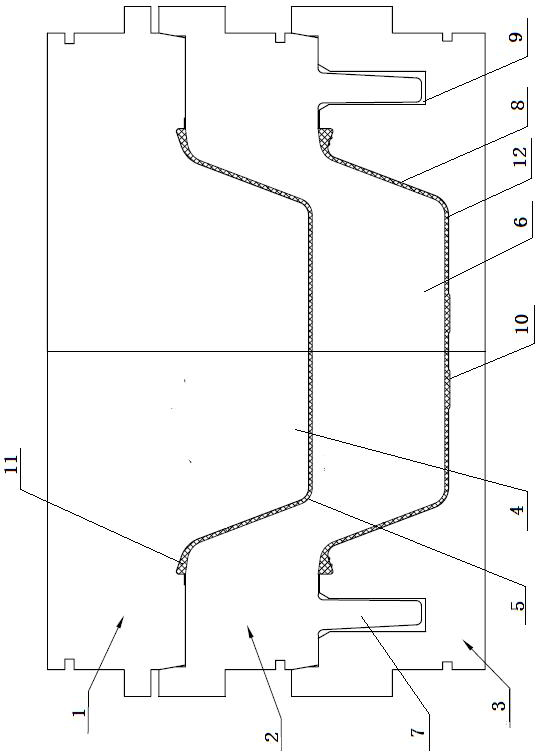

[0033] A kind of production technology of automobile brake air chamber rubber diaphragm, described production technology steps are as follows:

[0034] 1. Mold preparation

[0035] The mold is divided into three parts, respectively upper mold 1, middle mold 2 and lower mold 3, the upper part of the middle mold 2 cooperates with the upper mold 1 to form an upper mold cavity, and the lower part of the middle mold 2 cooperates with the lower mold 3 to form a lower mold cavity; the middle part of the lower surface of the upper mold 1 has a convex upper positioning head 4, and the middle part of the upper surface of the middle mold 2 has a concave preforming cavity 5, and the upper positioning head 4 matches the preforming cavity 5; The middle part of the lower surface of the middle mold 2 has a downwardly convex lower positioning head 6, and the lower surface of the middle mold 2 also has a downwardly convex diaphragm cloth positioning head 7, and the diaphragm cloth positioning h...

Embodiment 2

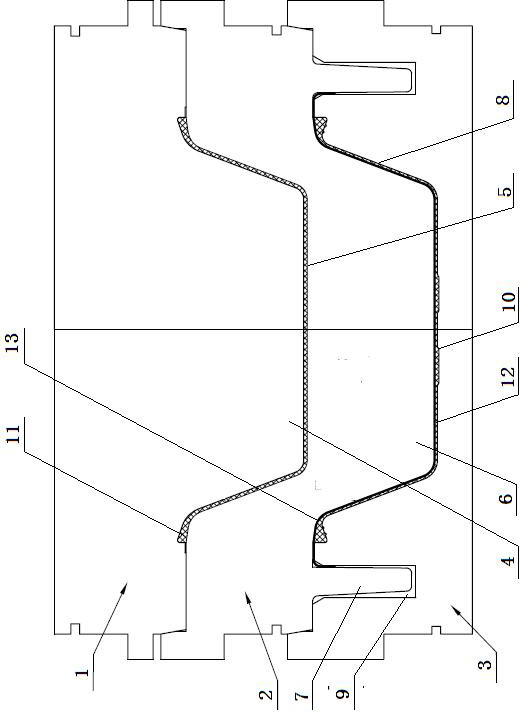

[0044] A kind of production technology of automobile brake air chamber rubber diaphragm, described production technology steps are as follows:

[0045] 1. Mold preparation

[0046] The mold is divided into three parts, respectively upper mold 1, middle mold 2 and lower mold 3, the upper part of the middle mold 2 cooperates with the upper mold 1 to form an upper mold cavity, and the lower part of the middle mold 2 cooperates with the lower mold 3 to form a lower mold cavity; the middle part of the lower surface of the upper mold 1 has a convex upper positioning head 4, and the middle part of the upper surface of the middle mold 2 has a concave preforming cavity 5, and the upper positioning head 4 matches the preforming cavity 5; The middle part of the lower surface of the middle mold 2 has a downwardly convex lower positioning head 6, and the lower surface of the middle mold 2 also has a downwardly convex diaphragm cloth positioning head 7, and the diaphragm cloth positioning h...

Embodiment 3

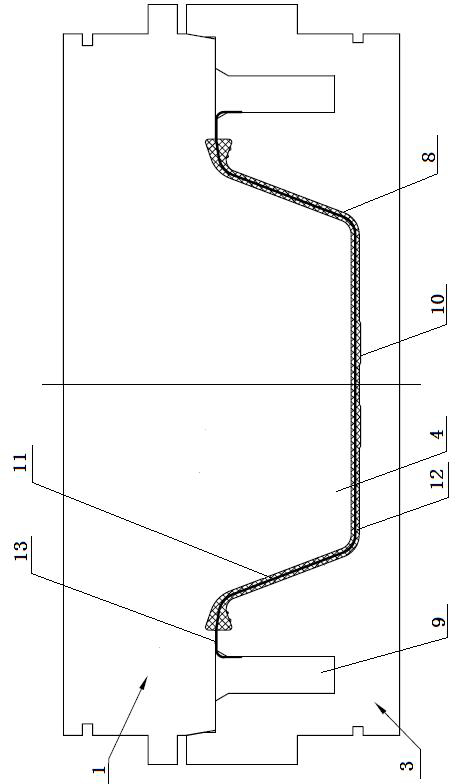

[0055] A kind of production technology of automobile brake air chamber rubber diaphragm, described production technology steps are as follows:

[0056] 1. Mold preparation

[0057] The mold is divided into three parts, respectively upper mold 1, middle mold 2 and lower mold 3, the upper part of the middle mold 2 cooperates with the upper mold 1 to form an upper mold cavity, and the lower part of the middle mold 2 cooperates with the lower mold 3 to form a lower mold cavity; the middle part of the lower surface of the upper mold 1 has a convex upper positioning head 4, and the middle part of the upper surface of the middle mold 2 has a concave preforming cavity 5, and the upper positioning head 4 matches the preforming cavity 5; The middle part of the lower surface of the middle mold 2 has a downwardly convex lower positioning head 6, and the lower surface of the middle mold 2 also has a downwardly convex diaphragm cloth positioning head 7, and the diaphragm cloth positioning h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com