Method for manufacturing thin-wall cylindrical member necking die

A manufacturing method and technology for thin-walled cylinders, which are applied in the field of mold manufacturing, can solve problems such as easy instability of workpieces, and achieve the effects of high production efficiency, simple operation and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

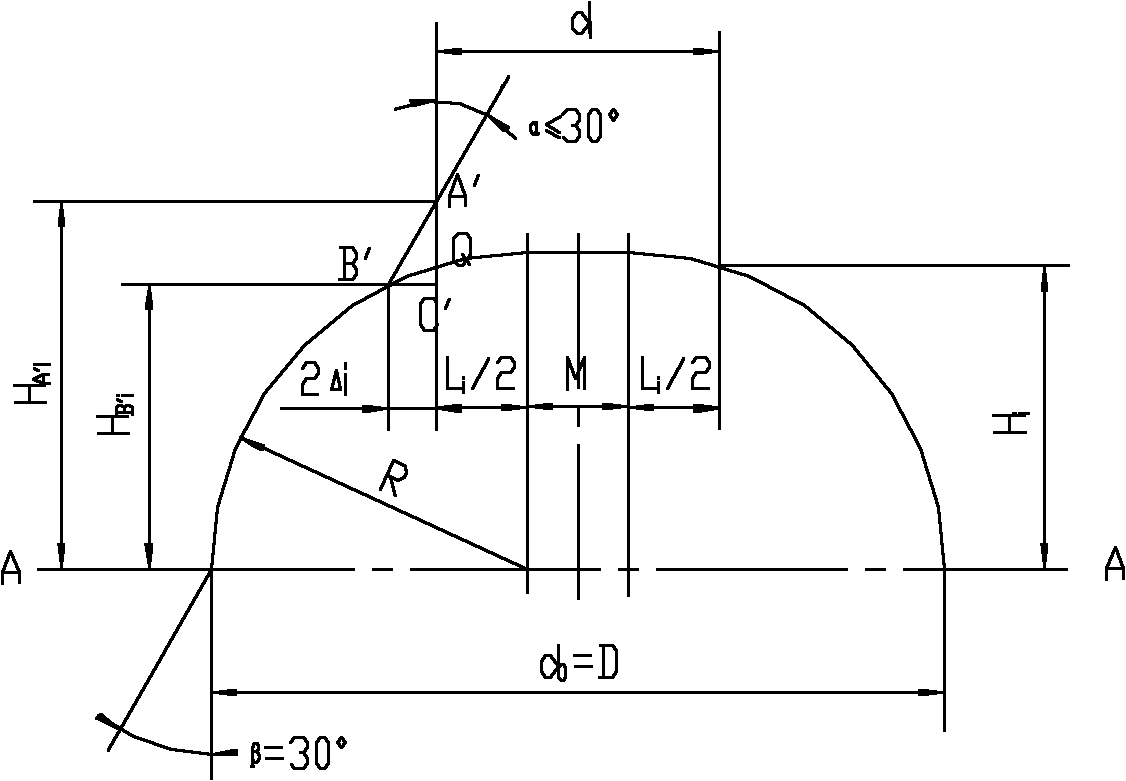

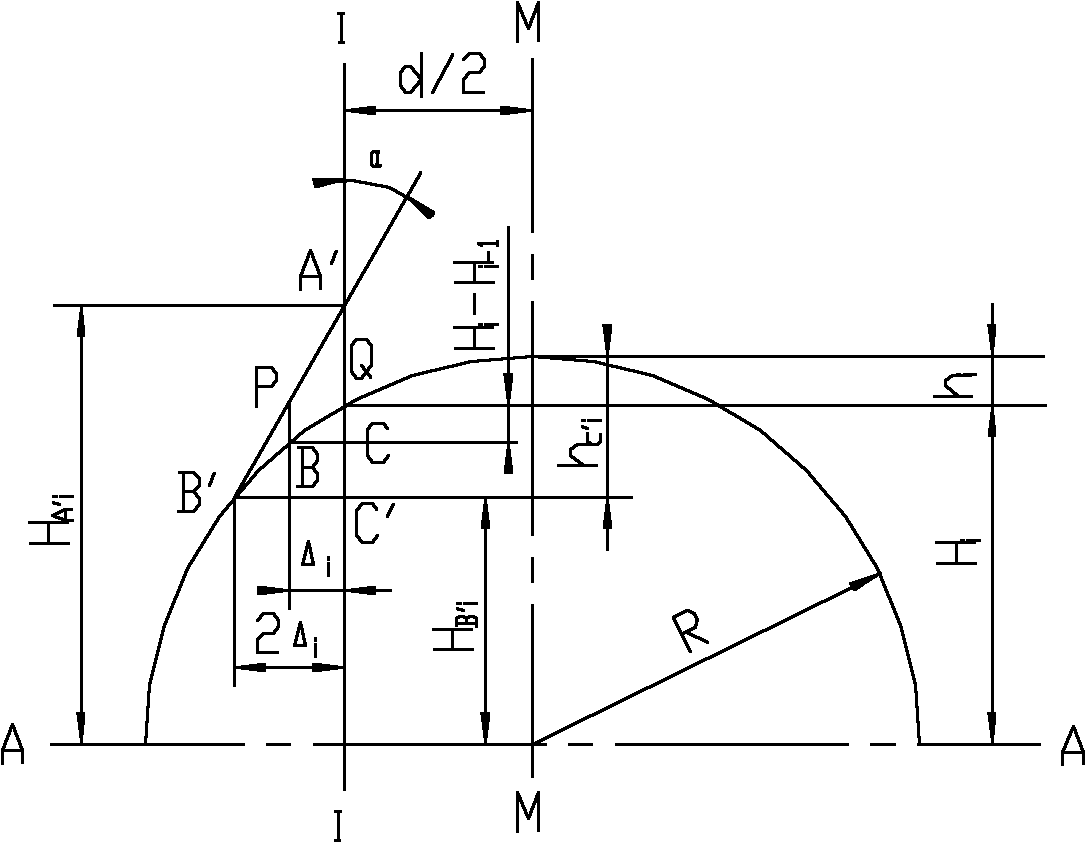

[0109] In a specific example, the necking coefficient and the necking pass are calculated with nine-pass necking parameters.

[0110] There is a cylindrical aluminum workpiece with a wall thickness of 2mm and a diameter of Φ80mm (M=0), which is required to be necked to Φ50mm. Calculate and determine the number of shrinking passes n and the shrinking coefficient mi of each pass and the shrinkage of each pass. Diameter di after the mouth.

[0111] calculation steps:

[0112] 1. Find the total shrinkage coefficient: known: D = Φ80; d = Φ50;

[0113] According to the formula:

[0114]

[0115] 2. Find the average shrinkage coefficient:

[0116] According to the empirical data m level = 0.945 ~ 0.960; according to the selection principle of m level, a. The material is thicker; b. The cylinder diameter is small. so choose m 平 = 0.945.

[0117] 3. Find the total number of shrinking passes n:

[0118] According to the formula: where: m 总 =0.625; m 平 = 0.945.

[0119] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com