Light partition board and preparation method thereof

A lightweight partition board and mass fraction technology, which is applied in building materials and other directions, can solve the problems of high cost of lightweight partition boards, poor function of finished boards, low performance of wall boards, etc., and achieves good water reduction effect and environmental protection. High performance and enhanced thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

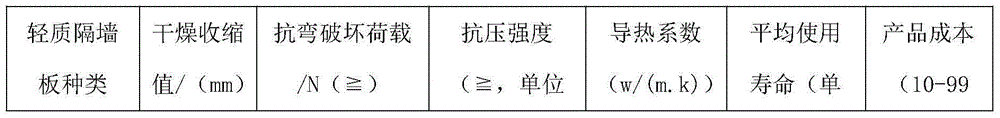

Examples

Embodiment 1

[0017] A lightweight partition board made of the following raw materials in parts by mass: 10 parts of glass fiber, 58 parts of iron slag powder, 22 parts of fly ash, 30 parts of quartz sand, 180 parts of magnesium oxide, and 13 parts of calcium carbonate , 15 parts of sodium carbonate, 2 parts of ferrous sulfate, 32 parts of modified sawdust powder;

[0018] The modified sawdust powder is prepared from the following raw materials in parts by mass: 108 parts of sawdust powder, 15 parts of plant ash, 10 parts of waste oil, 12 parts of starch, 2 parts of sodium dodecylbenzenesulfonate, and 0.5 parts of aluminum powder , appropriate amount of water.

[0019] The preparation method of this product adopts following steps:

[0020] (1) Add 10-12 parts of starch and 1-2 parts of sodium dodecylbenzenesulfonate to an appropriate amount of water, and heat to form a paste mixture, and add 100-120 parts of sawdust powder to the paste mixture , 15-20 parts of plant ash, 0.4-0.7 parts of ...

Embodiment 2

[0025] The steps and principles of this embodiment are basically the same as in Example 1, the difference being: 10 parts of glass fiber, 55 parts of iron slag powder, 20 parts of fly ash, 30 parts of quartz sand, 180 parts of magnesium oxide, calcium carbonate 12 parts, 15 parts of sodium carbonate, 2 parts of ferrous sulfate, 30 parts of modified sawdust powder;

[0026] The modified sawdust powder is prepared from the following raw materials in parts by mass: 100 parts of sawdust powder, 15 parts of plant ash, 10 parts of waste oil, 10 parts of starch, 1 part of sodium dodecylbenzenesulfonate, and 0.4 part of aluminum powder , appropriate amount of water.

Embodiment 3

[0028] The steps and principles of this embodiment are basically the same as in Example 1, the difference being: 12 parts of glass fiber, 60 parts of iron slag powder, 24 parts of fly ash, 35 parts of quartz sand, 200 parts of magnesium oxide, calcium carbonate 15 parts, 20 parts of sodium carbonate, 3 parts of ferrous sulfate, 35 parts of modified sawdust powder;

[0029] The modified sawdust powder is prepared from the following raw materials in parts by mass: 120 parts of sawdust powder, 20 parts of plant ash, 12 parts of waste oil, 12 parts of starch, 2 parts of sodium dodecylbenzenesulfonate, and 0.7 parts of aluminum powder , appropriate amount of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com