Dual oil supply pump

a technology of oil supply pump and pump body, which is applied in the direction of piston pump, positive displacement liquid engine, liquid fuel engine, etc., can solve the problems of pump drawing a greater amount of oil and consuming the other pump, and the packaging efficiency of the pump is large, so as to reduce the flow pulsation, prevent flow imbalance and cavitation during operation, and maximize the packaging efficiency of the pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

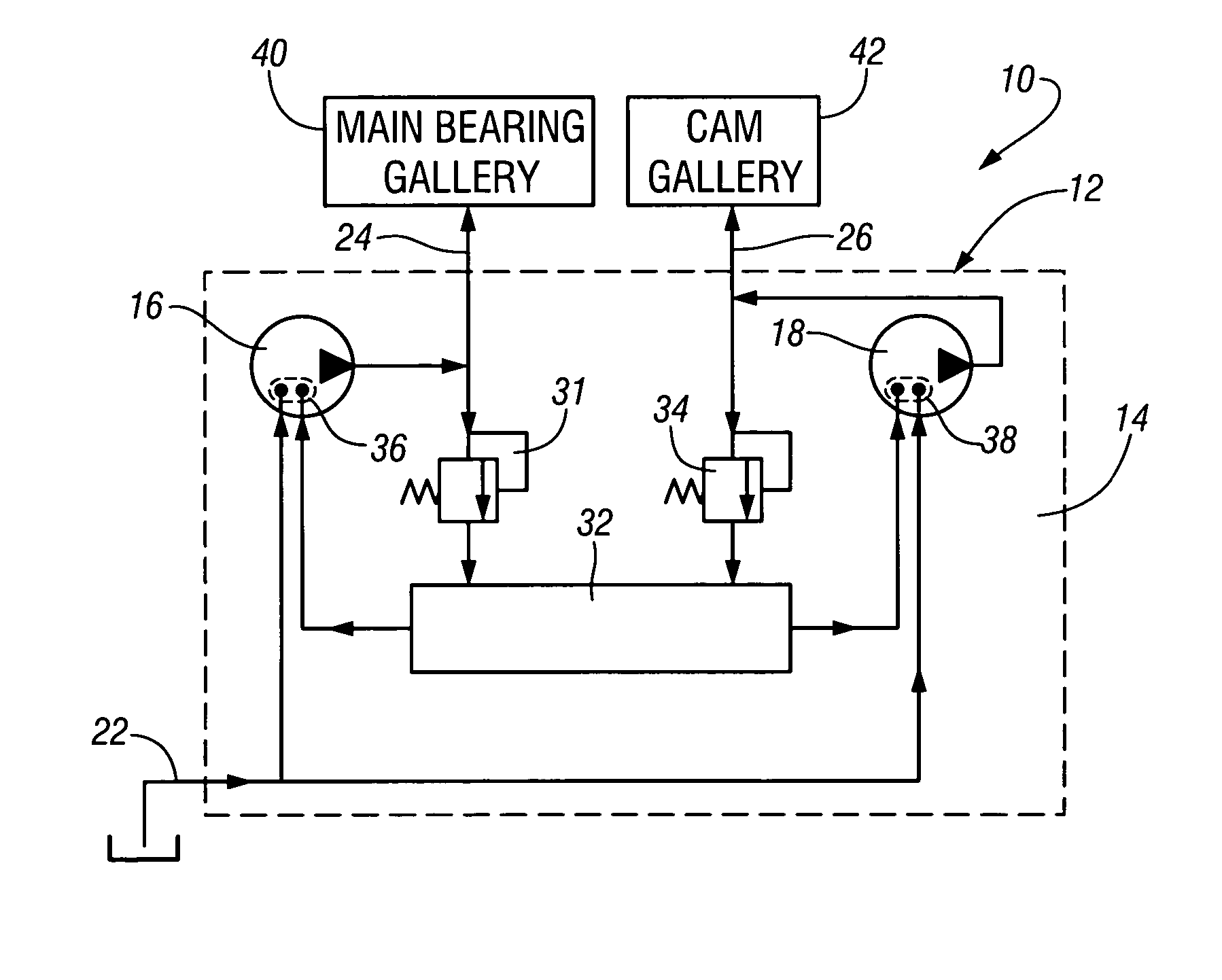

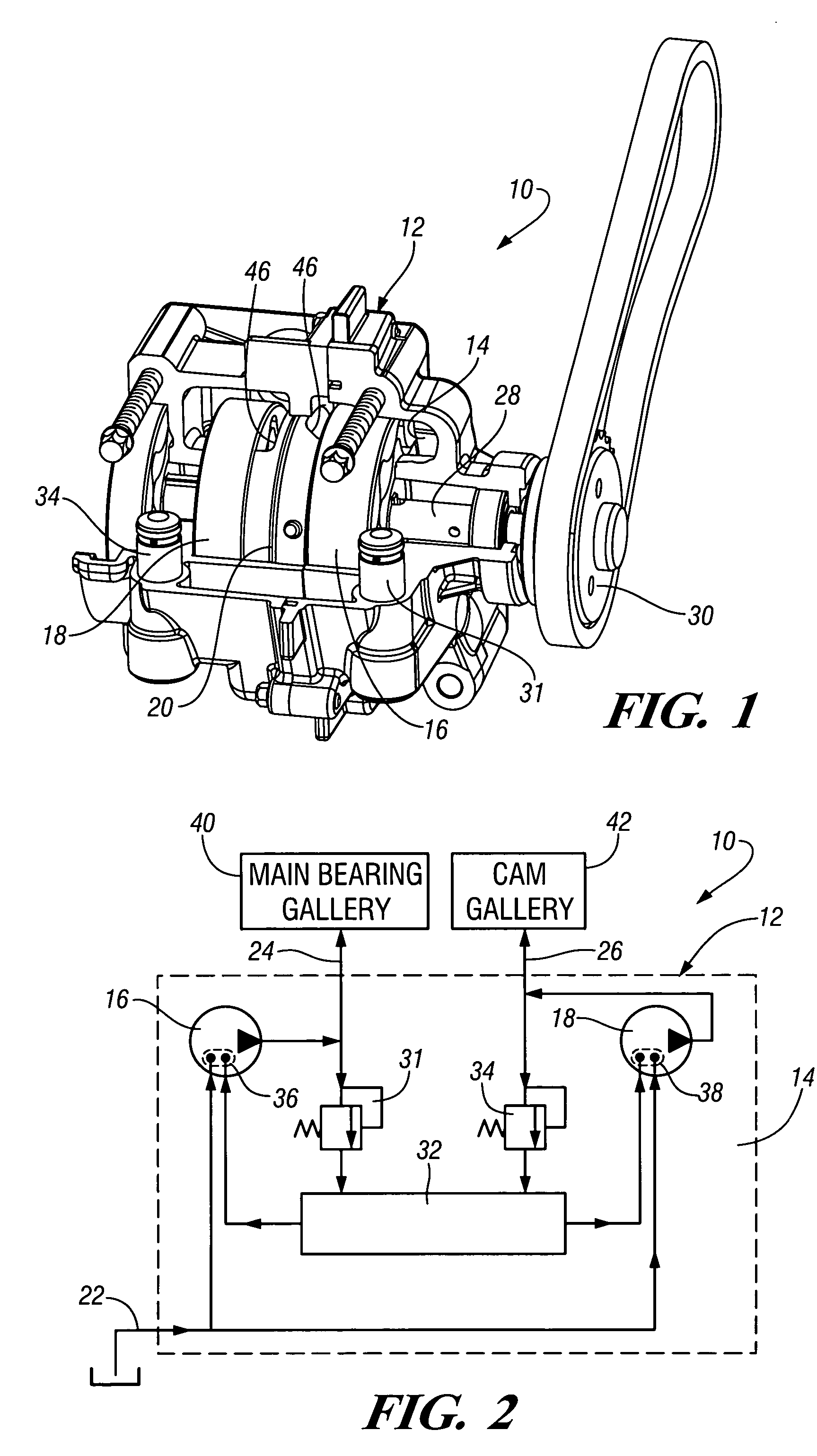

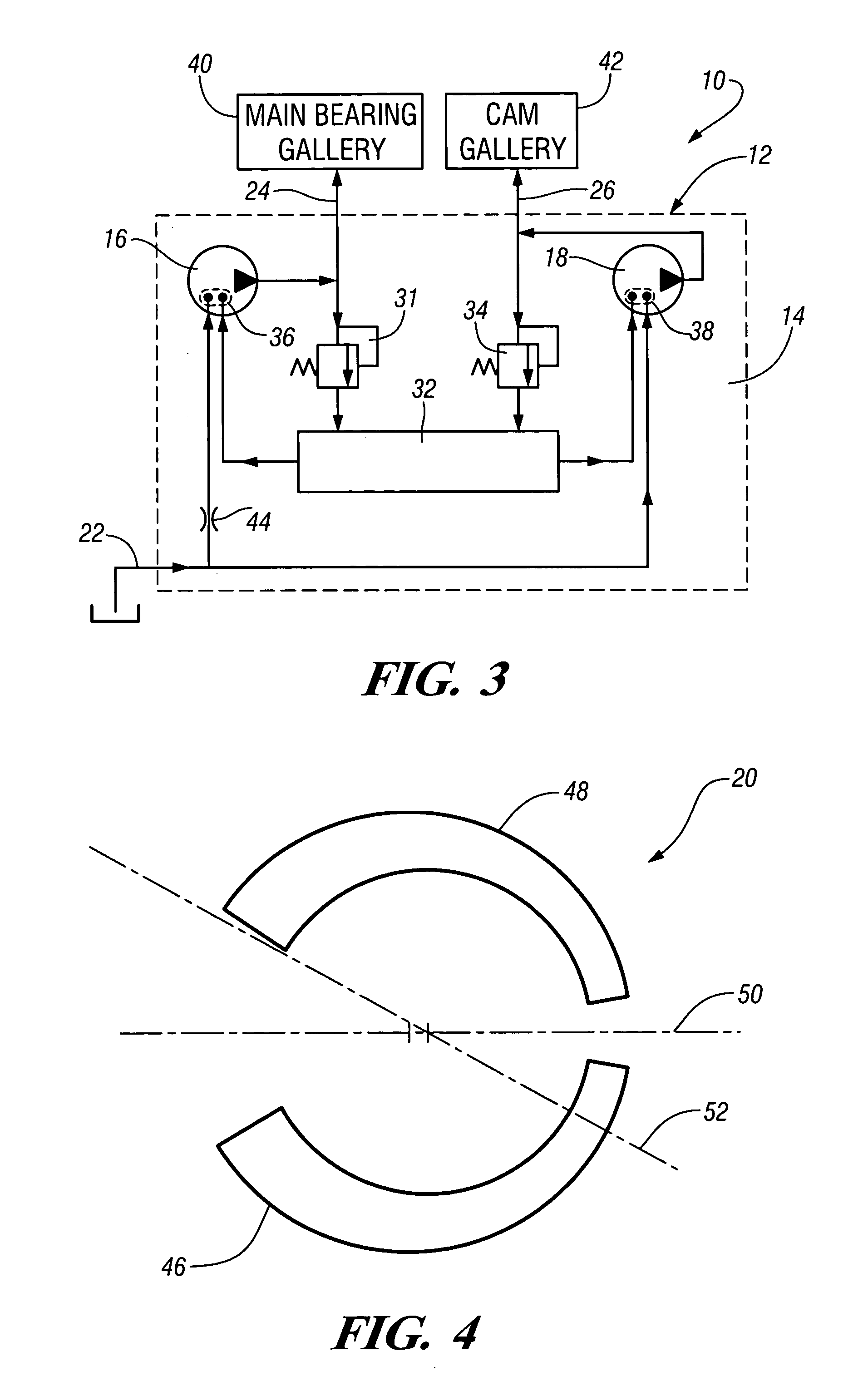

[0011] Referring now to FIGS. 1 and 2 of the drawings in detail, numeral 10 generally indicates an engine oil pump assembly. The pump assembly 10 includes a housing 12 defining an interior cavity 14 containing first and second pump mechanisms 16, 18 and a central port plate 20. The housing includes a common inlet 22 for feeding both pump mechanisms 16, 18, and first and second outlets 24, 26 connected with the separate pump mechanisms 16, 18. A shaft 28 having an external drive member 30 extends longitudinally through the housing 12 and drives both pump mechanisms 16, 18 at the same rotational velocity. Preferably, the pump mechanisms 16, 18 are positive displacement pumps such as gerotors. If desired, the first pump mechanism 16 may be advanced on the shaft 28 relative to the second pump 18 so that the pumps operate out of phase to reduce pulsation and vibration of the oil pump assembly 10. In addition, the pump mechanisms 16, 18 may have different displacements or flow rates if de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com