Piston rod and crosshead body connection adjusting structure

A technology of crosshead body and adjustment structure, which is applied to liquid fuel engines, parts of pumping devices for elastic fluids, parts of variable capacity pumps, etc. Affect the aesthetics of the assembly and other issues, and achieve the effect of no hidden safety hazards, convenient processing technology, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

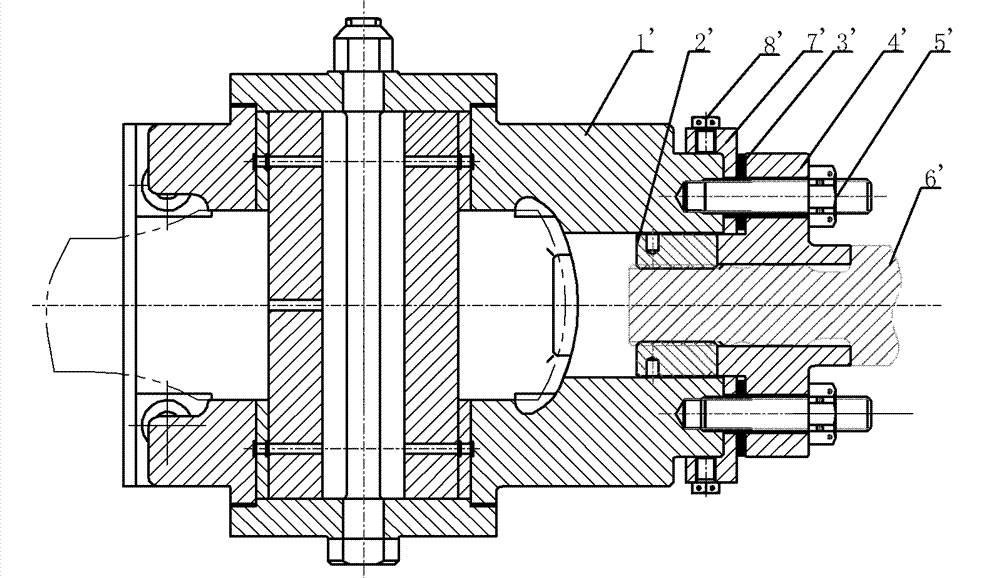

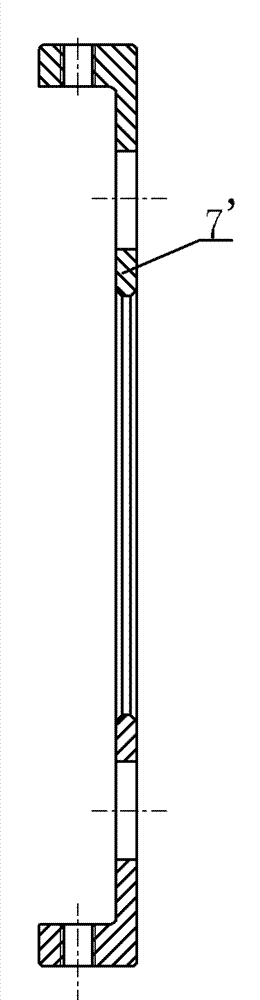

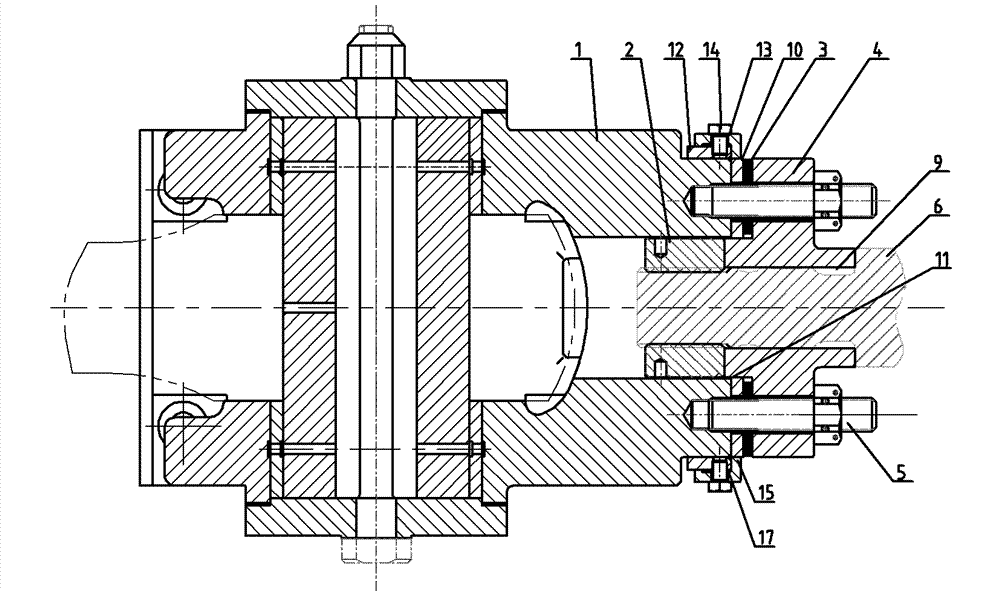

[0017] A connection adjustment structure between a piston rod and a crosshead body, see Figure 3 ~ Figure 7 : It includes a crosshead body 1, a hydraulic nut 2, a piston rod 6, a gasket 3, and a flange 4. A hydraulic nut 2 is arranged in the inner hole of the front end of the crosshead body 1, and the piston rod 6 runs through the center hole 9 of the flange 4. After positioning on the hydraulic nut 2, a gasket 3 is arranged between the axial outer end surface of the crosshead body 1 and the positioning surface of the flange 4, and the inner end surface of the gasket 3 and the axial outer end surface of the crosshead body 1 The plug is equipped with an adjustable gasket 10. The adjustable gasket 10 is an adjustable gasket in the shape of a flange. The adjustable gasket 10 is set on the inner side of the flange 4. The surface cover is equipped with an adjustable ring 12, and the pressing piece 13 is evenly distributed on the outer ring surface of the adjustable ring 12 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com