Construction method for grooving and punching on concrete

A construction method and concrete technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of labor-intensive and time-consuming, unguaranteed construction quality, complicated construction methods, etc., to achieve convenient removal, save manpower, The effect of easy control of dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

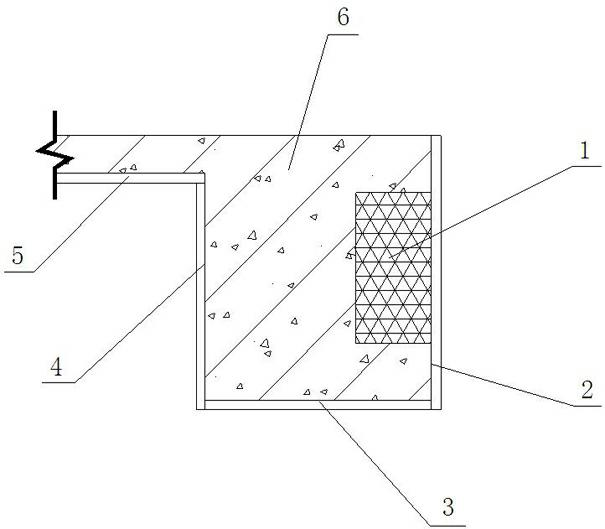

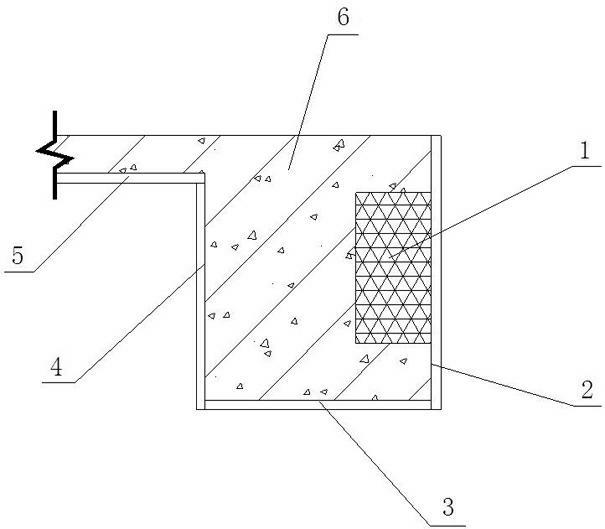

[0007] 1. Make a foam strip 1 with the same size as the slot or hole.

[0008] 2. Fix the foam strip 1 on one side of the template 2.

[0009] 3. The formwork 2 and other formworks 3, 4 and 5 are surrounded to form a concrete pouring cavity and relatively fixed.

[0010] 4. Pour concrete mortar 6 into the cavity.

[0011] 5. After maintenance, after the concrete mortar 6 is cured, remove all formworks 2, 3, 4, and 5, and remove the foam strip 1, leaving the groove or hole required for the design at the position where the original foam strip 1 was located.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com