One-dimensional magnetic assembly array with single nanoparticle precision and its preparation method and application

A nanoparticle and magnetic nanoparticle technology, applied in the field of one-dimensional arrays, can solve the problems of complex preparation method and uneven morphology, and achieve the effects of simple preparation method, uniform morphology and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

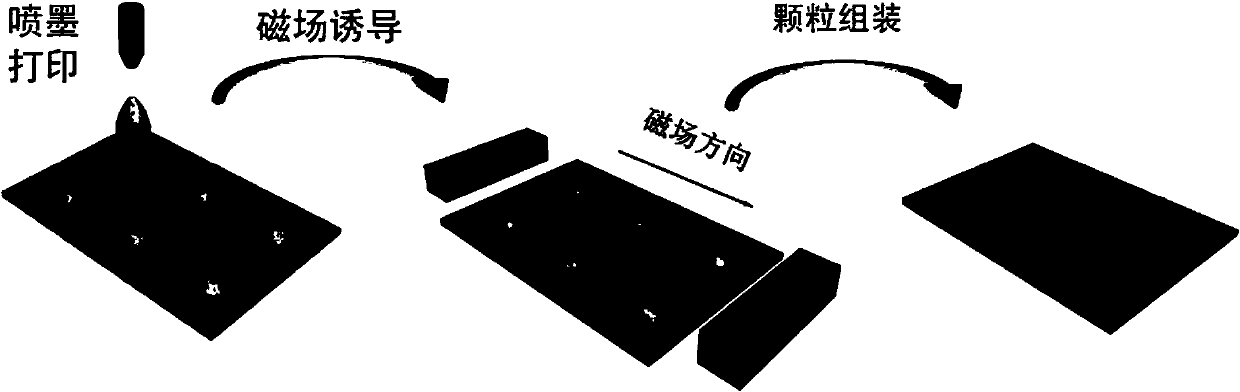

[0021] According to a method for preparing a one-dimensional magnetic assembly array provided by the present invention, the method comprises the following steps:

[0022] (1) jetting aqueous ink containing magnetic nanoparticles onto the surface of the substrate in the form of an array by inkjet printing, the receding angle of the surface of the substrate is 3-30°; and

[0023] (2) Under the magnetic field induction, the ink array printed on the surface of the substrate is dried and assembled.

[0024] The concentration of the ink of the present invention reflects the number of particles in the droplet, and determines the distance and interaction between particles. Due to the fact that the distance between particles of the same concentration is also different in the liquid droplets of phase bodies with different spreading areas. Therefore, in the region of the receding angle (RCA) of 3-30°, the RCA is smaller, and the spreading area of the droplet is small at this time, and...

Embodiment 1

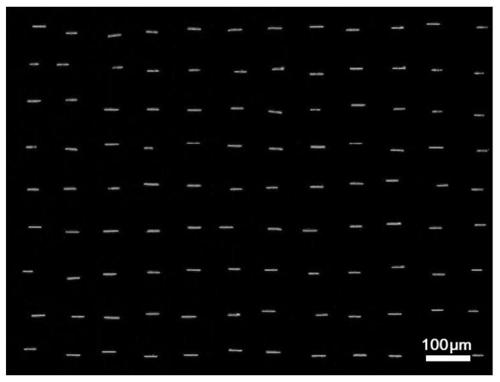

[0069] 1. The preparation of a one-dimensional magnetic assembly array with single nanoparticle precision, including the following steps:

[0070] (1) The RCA of the cut untreated polished silicon wafer (thickness: 380±10 μm, purchased from Tianjin Semiconductor Research Institute) is 15.3°, and set aside;

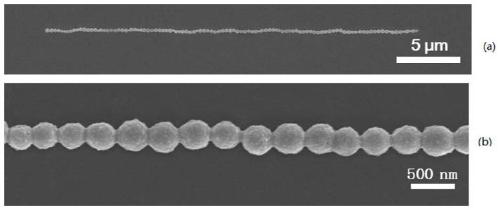

[0071] (2) iron ferric oxide-benzenesulfonic acid maleic anhydride copolymer magnetic ball, namely poly(styrenesulfonic acid maleanic anhydride) sodium salt-coated iron ferric oxide nanometer microsphere is to utilize hydrothermal method to prepare and obtain, will 0.5 Dissolve gPSSMA in 20ml ethylene glycol, then add 0.54g FeCl 3 ·6H 2 O and 1.5g Na 3 C 6 h 5 o 7 Stir the mixed liquid magnetically at room temperature for 3 hours, then transfer it to a 25ml reaction kettle, and react for 12 hours at 200°C; when it reaches room temperature, wash it with deionized water and ethanol mixture for 3 times to obtain superparamagnetic nano Particles, the saturation magnetic ...

Embodiment 2

[0081] The preparation of a one-dimensional magnetic assembly array with single nanoparticle precision includes the following steps:

[0082] (1) Sputter the cut mica sheet with oxygen plasma, the power of sputtering is 20W, and the time of sputtering is 10s, to obtain a highly adherent substrate with a receding angle of 7.3°, for subsequent use;

[0083] (2) 0.25mmol ZnCl 2 , 0.5mmol FeCl 3 ·6H 2 O, 1.5mmol C 6 h 5 Na 3 o 7 2H 2 O and 3mmol uric acid were dissolved in 20mL distilled water, and then 0.3g polyacrylamide was added to the above solution. The mixed liquid was magnetically stirred at room temperature for 3 hours, then transferred to a 25 ml reaction kettle, and reacted at 200° C. for 12 hours. After reaching normal temperature, wash three times with deionized water and ethanol mixture to obtain monodisperse polyacrylamide-coated zinc iron ferrite Zn 0.41 Fe 0.59 Fe 2 o 4 The magnetic ball, that is, zinc iron ferrite-polyacrylamide nano magnetic ball, is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com