Hard alloy integral type expansion-extrusion countersink for machining deep hole

A cemented carbide, integral technology, used in metal processing equipment, manufacturing tools, drilling/drilling equipment, etc., can solve the problem of long process time, and achieve easy processing, good manufacturing process, and easy dimensional accuracy control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

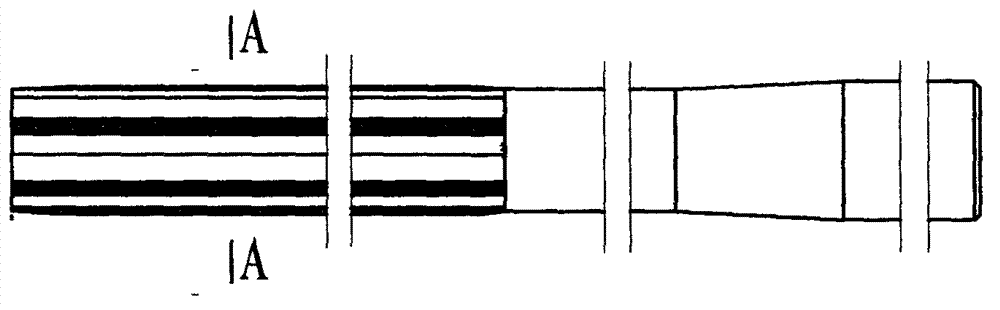

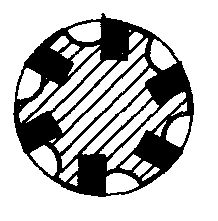

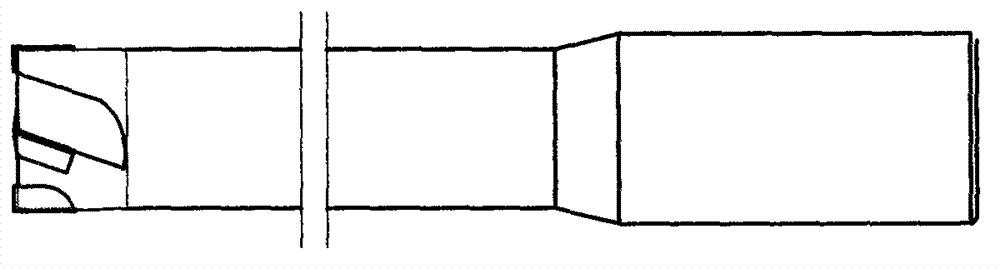

[0015] The structure of the present invention is: a round cutter bar 1 comprising cemented carbide, characterized in that: the first half of the round cutter bar 1 of cemented carbide is evenly provided with 4-6 twist drill-shaped spiral grooves 3, and the spiral grooves 3 The rise angle is 20-25°; the outer circular surface of the spiral body 5 between two adjacent spiral grooves 3 protrudes radially from the front surface of a spiral blade 2, and the circumferential bandwidth of the spiral blade 2 is 0.5-1.2mm. The radial protrusion height is 0.3-0.5mm, and the back angle is 0°; the central angles of the outer circular gap of the spiral groove 3 and the outer circular surface of the spiral body 5 are equal and equal to 180° divided by the number of spiral grooves 3 The front end surface of each helix 5 is concave, and the front end surface of each helix 5 is provided with a radial blade 4 on the front end surface of the helix 5 raised between the end of the helical blade band...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com