A stress-controlled 3D printing remanufacturing method for metal parts

A metal parts, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of reducing the fatigue strength and wear resistance of parts, combining interface fatigue, shortening the fatigue life of parts, etc., to improve the service life and save operating costs. , the effect of the overall intensity balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

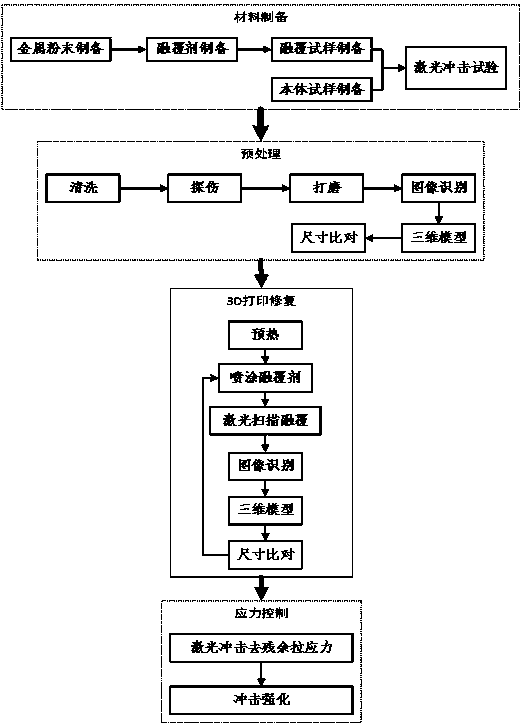

[0027] Such as figure 1 As shown, a stress control 3D printing remanufacturing method of a metal part of the present invention includes a material preparation stage: preparing a metal part body sample and a fused sample, and performing a stress test on the sample with laser shock to obtain the same residual compressive stress. laser parameters;

[0028] Pretreatment stage: Pretreatment of the metal parts to be repaired to make the surface meet the repair requirements, and use image recognition methods to determine the repair area and repair margin of the parts;

[0029] 3D printing repair stage: Install the pretreated metal parts to be repaired on the laser 3D printer, and use the laser 3D printer to repair the metal parts layer by layer, so that the size of the repaired part reaches the original design size of the part;

[0030] Stress control stage: After the repair is completed, laser shock is used to eliminate the residual tensile stress in the repaired part and its surro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com