A structure and method for adjusting the natural frequency of a turbine integral blisk blade

An integral blisk and natural frequency technology, applied in the direction of blade support components, engine components, machines/engines, etc., can solve the problems of long design and processing cycle, affecting aerodynamic performance, small range, etc., and achieve large engineering practical value, size Easy to control precision and good workmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through specific embodiments:

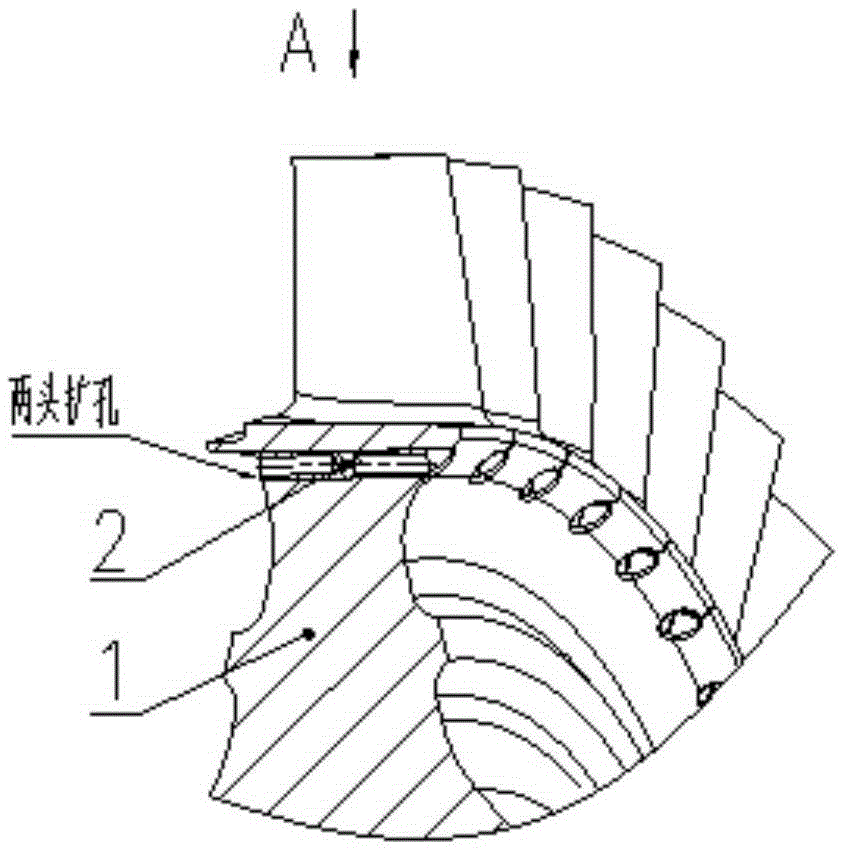

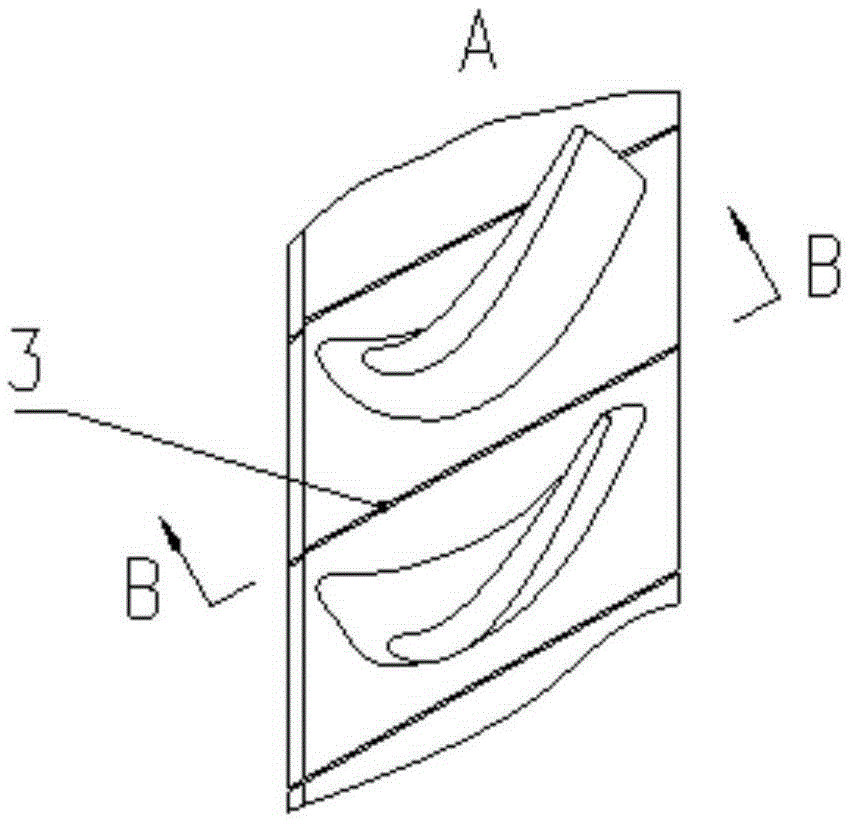

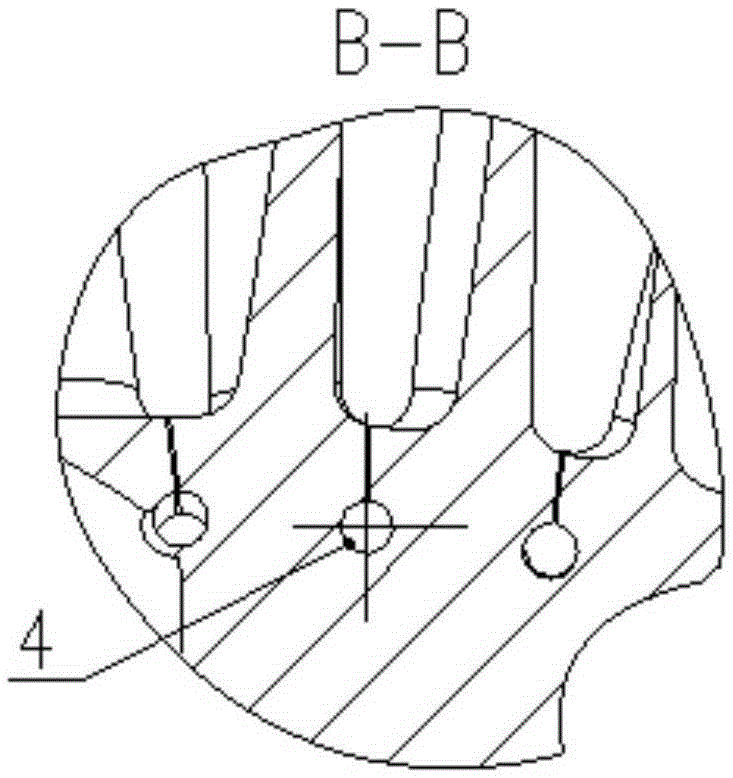

[0019] See also figure 1 , figure 2 with image 3 ,among them, figure 1 It is a schematic diagram of the natural frequency adjustment structure of the integrated turbine blisk blade of the present invention. figure 2 Yes figure 1 Schematic diagram of A direction, image 3 Yes figure 2 Section B-B. There is a slit 3 of a certain width between each blade of the integrated turbine blisk 1 of the present invention. The slit forms a certain angle α with the axis of the engine. The radial depth of the slit is determined by the frequency value that needs to be adjusted. The width is 0.2~0.4, and the depth is 3~7mm from the rim. The greater the frequency of adjustment, the greater the depth value. The included angle range can better contain the root leaf shape. The end of each slit is processed with an anti-cracking hole 4. The crack arrest hole is circular with a diameter of 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com