Drawing forming process of aluminum alloy deep paraboloid cylindrical part

A forming process and paraboloid technology, applied in forming tools, metal processing, metal processing equipment, etc., can solve the problems of difficult control of surface quality and dimensional accuracy of parts, poor product consistency, low drawing efficiency, etc., and achieve dimensional accuracy. , Simple design, high drawing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

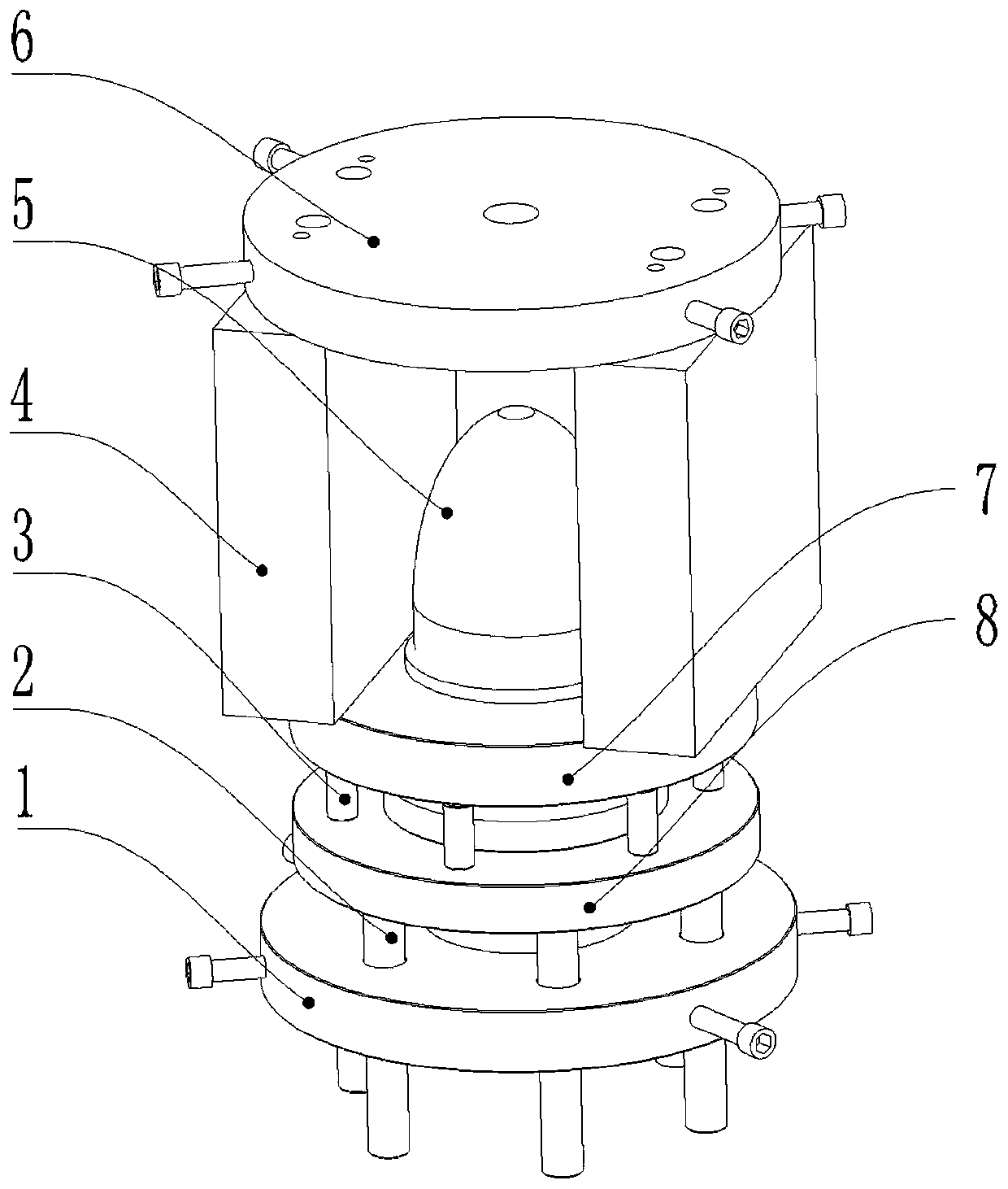

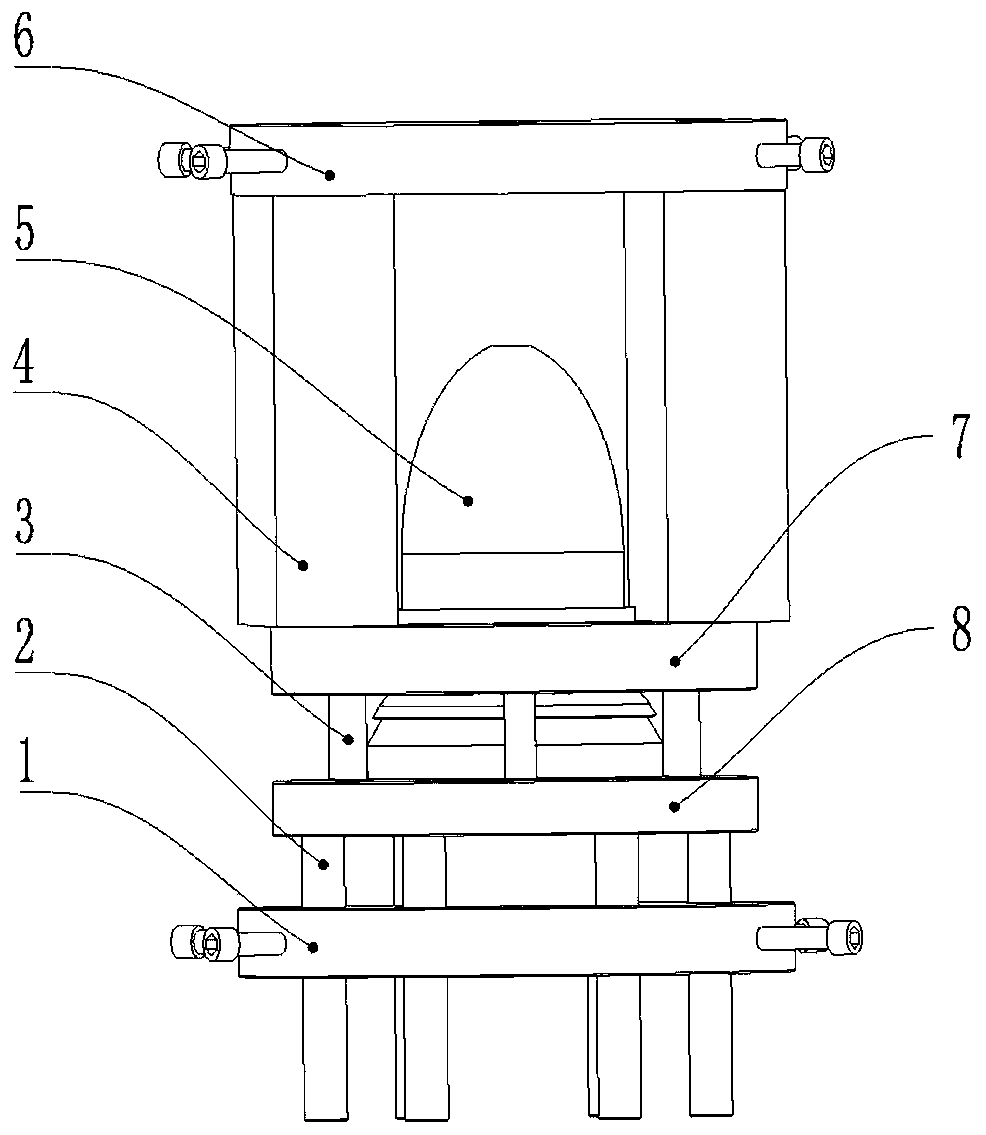

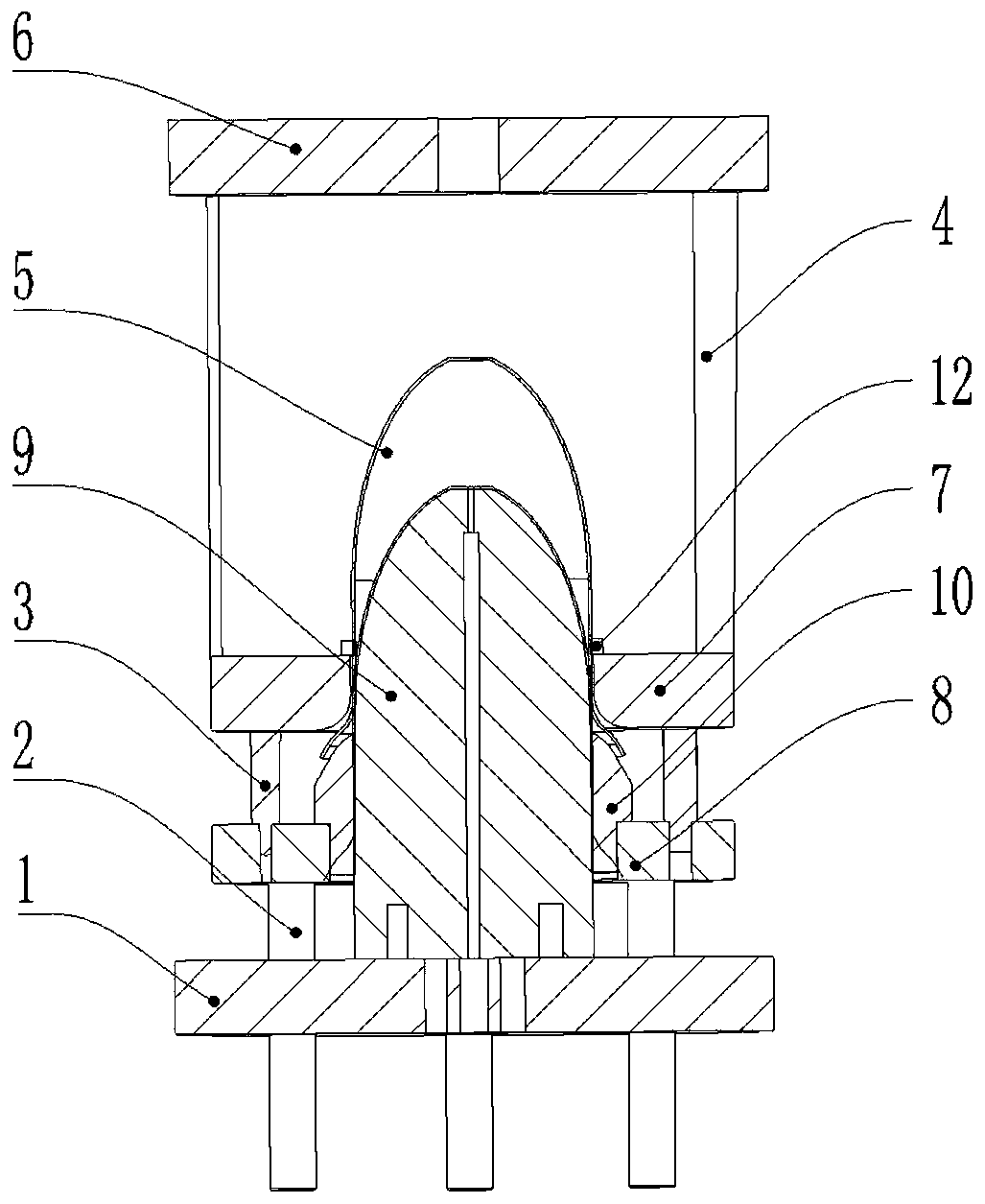

[0042] Such as Figure 1-9 As shown, a deep drawing forming process of an aluminum alloy deep parabolic cylindrical part comprises the following steps:

[0043] Step 1: Calculate and determine the diameter D of the blank, and determine the diameter of the blank according to the principle of equal surface area. The blank here can be a circular plate with a thickness of 2 mm;

[0044] Step 2: Deep drawing the blank into a large cylinder 51 whose diameter is equal to the cylinder diameter of the deep paraboloid 111. The shape of the blank, the diameter of the blank and the minimum drawing coefficient of the aluminum alloy sheet determine the number of drawing. Under the premise that the diameter of the large cylinder 51 is equal to the diameter of the deep paraboloid 111 and the large end 52 has an oblique flange edge, calculate Determine the size and drawing process diagram of each drawing process;

[0045] Step 3: Take the inclined flange edge of the big end 52 as the stress ...

Embodiment 2

[0051] Such as Figure 1-9 As shown, on the basis of the above-mentioned embodiments, this embodiment provides a more specific deep-drawing process. That is, in step 1, the calculation and determination of the diameter of the blank is based on the surface area of the blank equal to the surface area of the qualified part 11 plus the trimming allowance, and the diameter D of the blank is calculated.

[0052] Preferably, in step 2, the drawing coefficient is calculated according to the formula m=d / D, and the drawing process diagram and size are determined; wherein, d is the diameter of the neutral layer of the deep paraboloid 111 cylinder, in millimeters, and D is the diameter of the blank , in millimeters. Calculate the drawing diameter of this process according to the drawing coefficient of each time and the diameter of the previous process, determine the arc radius of drawing, and then calculate the drawing height according to the principle that the surface areas before a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com