Cathode system for electric demisting device with conductive fiberglass reinforced plastic

A conductive glass fiber reinforced plastic and electrostatic demister technology, applied in the direction of electrode structure, electrostatic separation, etc., can solve the problems of difficult adjustment of cathode wire spacing, unstable operation of electric field, and increased size error, etc., to achieve small shaking, easy installation and disassembly Convenience and low gas resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

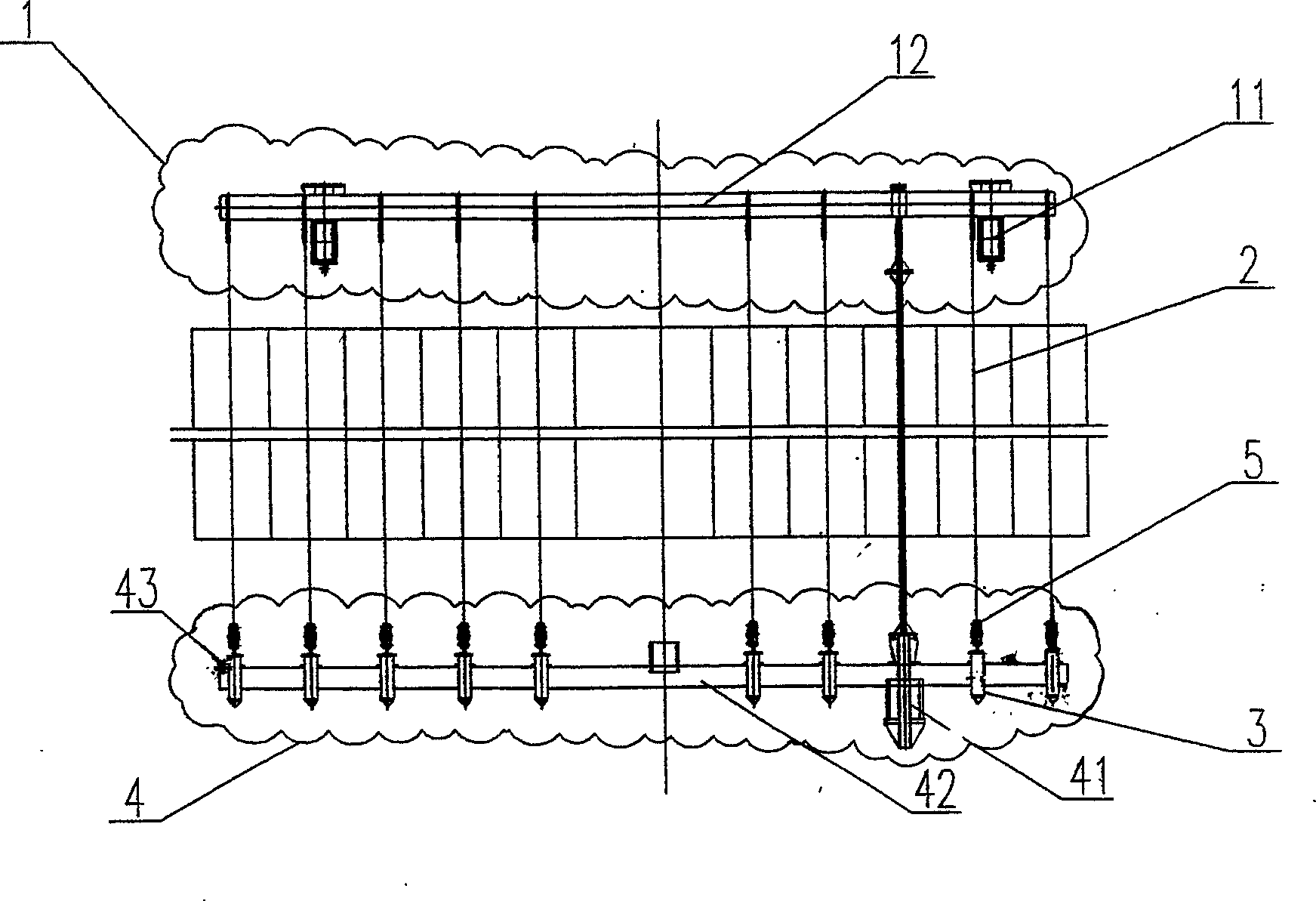

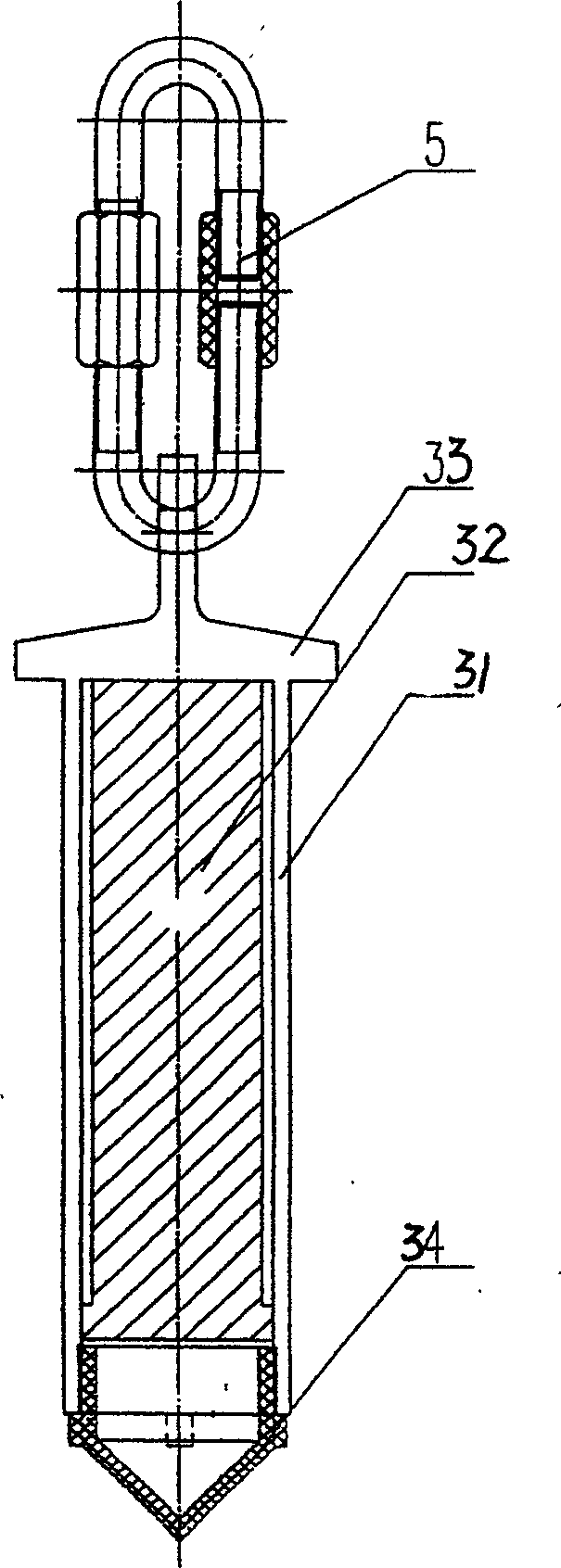

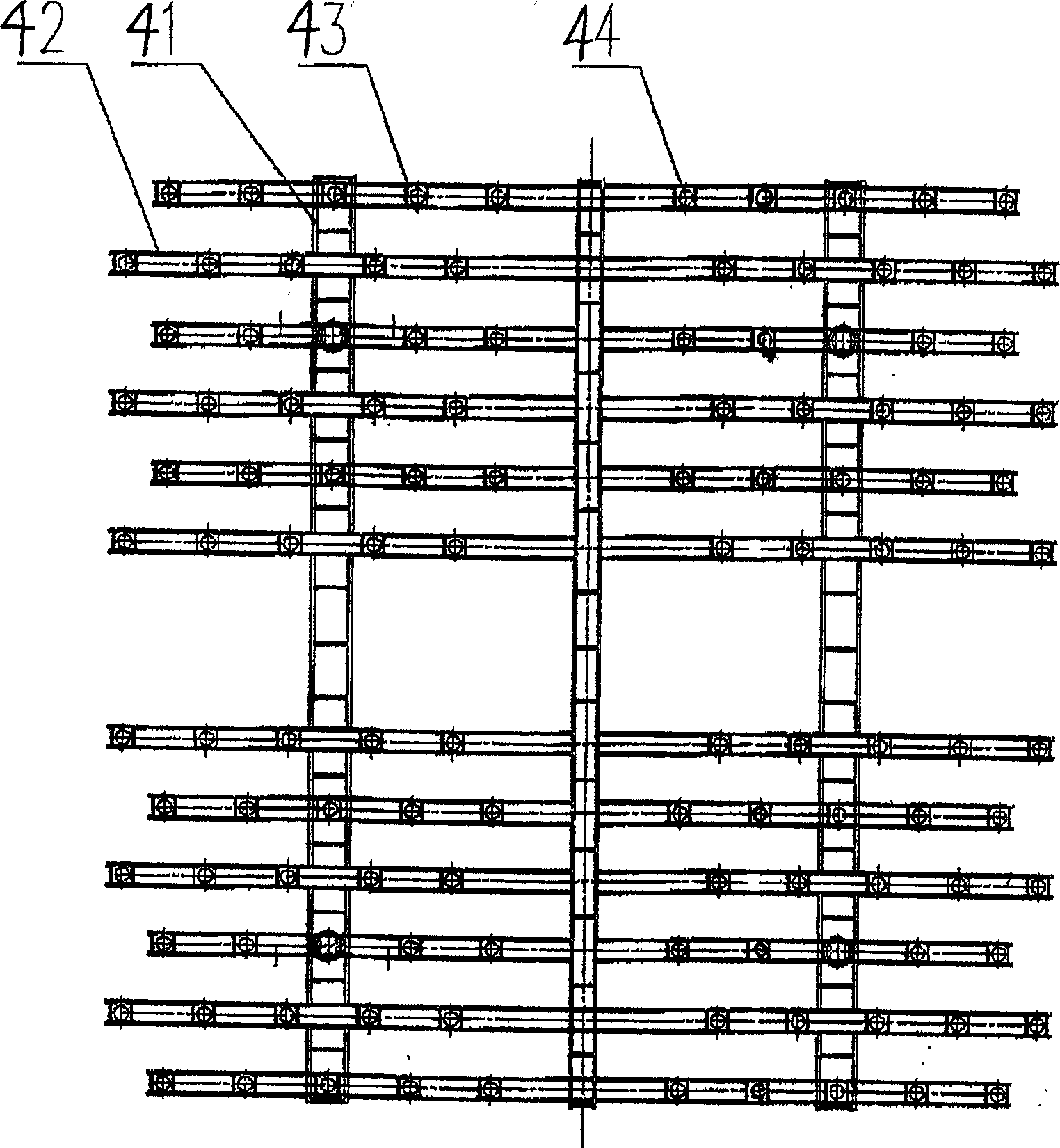

[0013] Embodiment 1, a cathode system for a conductive FRP electrostatic demister, consists of a cathode load beam (1), a cathode wire (2), a weight (3) and a lower cathode frame (4), the weight (3) is made of a closed plastic outer The cylinder body (31) and the plumb weight (32) inside it are composed, the upper cover of the outer cylinder body is a slope cover (33), the bottom is closed with a conical nut (34), and the upper end of the cathode wire (2) is hooked to the cathode load. On the beam, the lower end is connected on a hook (5) formed by double U-shaped bolts into an O-type, and the other end of the hook (5) is screwed on the slope cover ( 33) The upper and lower cathode frames (4) are composed of plastic main beams (41) and support beams (42), and the support beams (42) are correspondingly provided with opening adjustment plates (43), and the outer cylinder of the weight (3) (31) pass through the adjustment plate (43) hole (44).

Embodiment 2

[0014] Embodiment 2, with reference to Example 1, the main beam and support beam of the lower cathode frame are made of glass fiber reinforced plastics, and each beam slat is placed sideways, and the cathode load beam (1) is directly connected to the small beam by two main beams (11). Beams (12) consist of beams (12), small beams and main beams are fastened by beam clips (13), and the cross section of the main beams (11) is tapered, and each beam is coated with carbon fiber glass fiber reinforced plastics and lead plates in turn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com