Curved-surface display screen, and bearing framework and forming method thereof

A technology of display screen and curved surface, applied in the direction of supporting machine, machine/stand, static indicator, etc., can solve the problems of poor display effect and difficult manufacturing of curved LED screen, and achieve easy processing, easy control of dimensional accuracy, elimination of The effect of cumulative error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

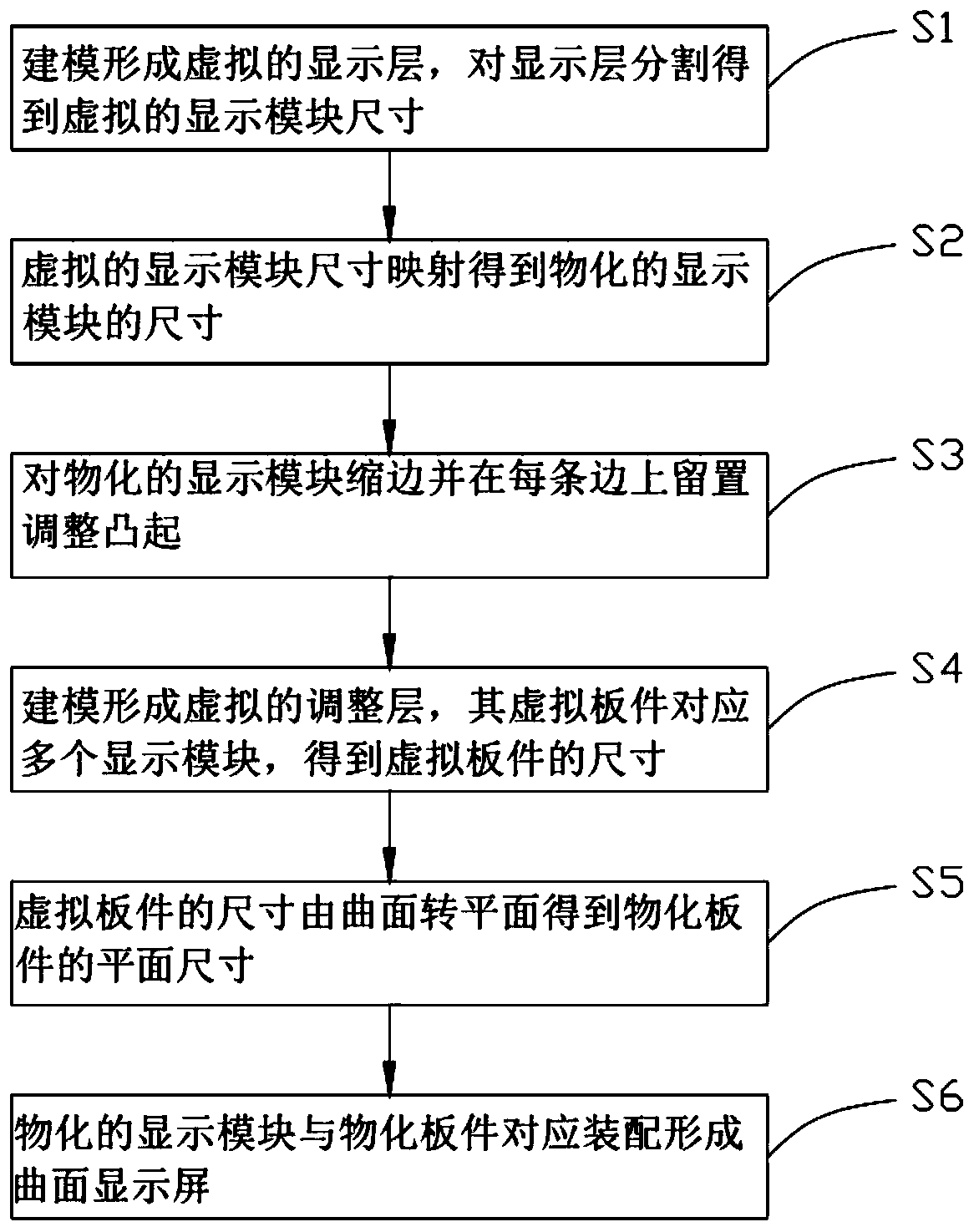

[0063] like figure 1 and 13 As shown, this embodiment provides a method for forming a curved display screen, comprising the following steps:

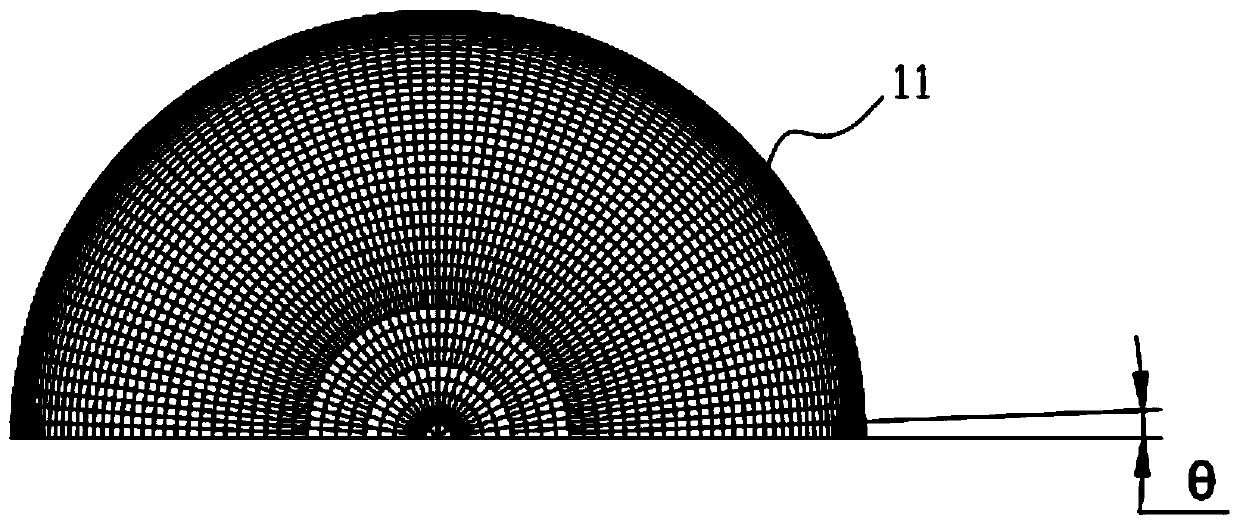

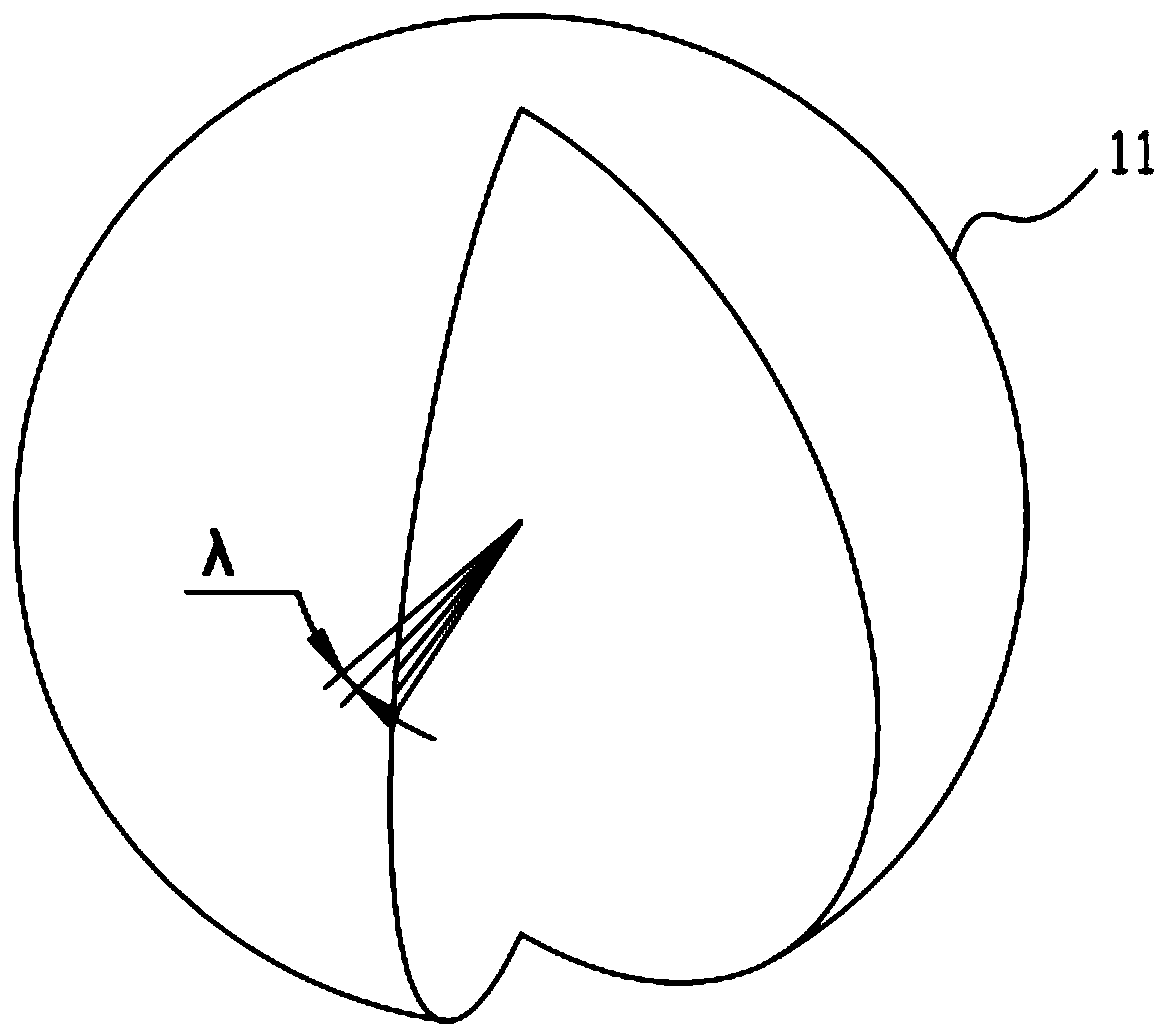

[0064] S1: use modeling software to model and form a virtual display layer 11 in the form of a curved surface, carry out average virtual segmentation of the display layer 11 along the horizontal and vertical directions respectively, and obtain a plurality of virtual display modules 111, see Figure 2-3 In this embodiment, the spherical screen-shaped display layer 11 is taken as an example, and the display layer 11 is segmented horizontally and vertically with fixed angles θ and λ, respectively, to carry out average virtual segmentation.

[0065] Then calculate the size of each virtual display module 111, the calculation method of the size of the virtual display module 111 is as follows, see Figure 4 , define the plane where the cross-sectional circle with a diameter of D is the equatorial plane, symmetrically divide the display layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com