Method and device of shot peening for surface of metal component by means of light-water complex

A metal component, shot peening technology, applied in the field of laser processing and material surface modification, can solve the problem of insufficient restraint strength, achieve overall grain refinement, improve the mechanical properties and mechanical properties of materials, and uniform residual compressive stress distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

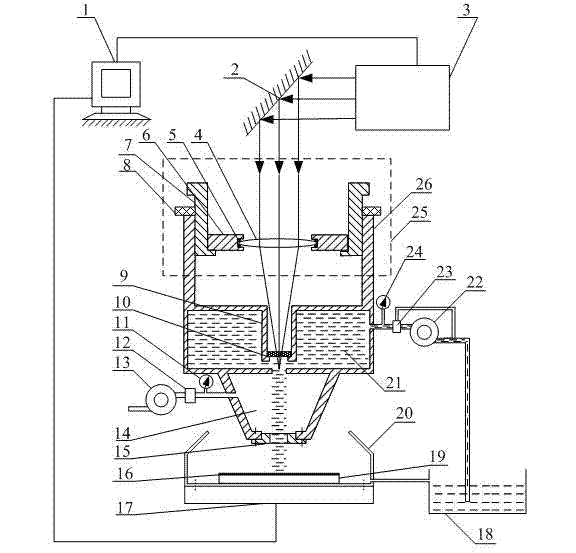

[0039] Such as figure 1 , 3 shown.

[0040] A device for shot-peening the surface of metal components using a light-water complex, including: a water storage chamber 21 and a hydraulic pump 22; a high-pressure air chamber 14 and an air pump 13; a five-axis linkage numerical control workbench 17; a focusing lens focusing system 25 ; Nd:YAG solid-state laser 3; mirror 2; hydraulic indicator plate 24; computer control system 1.

[0041] A focusing lens focusing system 25, a water storage chamber 21 and a high-pressure air chamber 14 are arranged in the cavity 26. A cylindrical light guide cavity 9 is built in the water storage cavity 21, and a high-voltage resistant Glass 10, 3 mm below the high-pressure resistant glass 10 is the water outlet of the water storage chamber 21, and the high-pressure deionized water is sprayed out through the water outlet to reach the inside of the high-pressure air chamber 14; the laser beam emitted by the Nd:YAG solid-state laser 3 passes through...

example

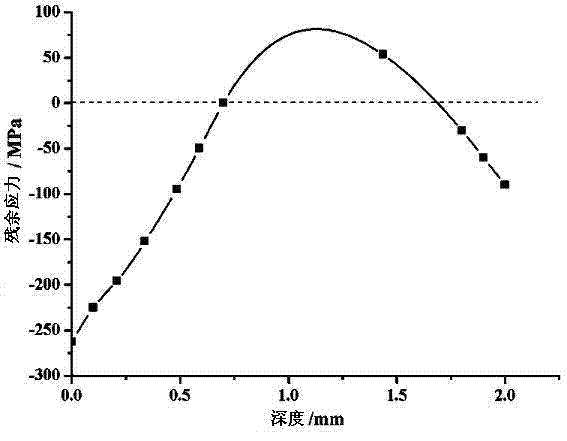

[0045] Example: Light-water complex shot peening strengthened 6061-T6 aluminum alloy

[0046] Place a 6061-T6 aluminum plate 19 with a size of 20 mm×20 mm×4 mm in the splash-proof chamber 20, coat the surface of the 6061-T6 aluminum plate 19 with an energy absorbing layer 16, turn on the hydraulic pump 22, and adjust the hydraulic pressure regulating valve 23 When the pressure reaches 60 MPa, the water column impacts the surface of the 6061-T6 aluminum plate 19 at this pressure; at the same time, the air pump 13 is turned on, the gas pressure is adjusted to 15 MPa, and the purified air at this pressure is sent to the high-pressure air chamber 18, and the gas is sprayed through the nozzle at the lower end. Turn on the computer control system 1 to issue instructions to the Nd:YAG solid-state laser 3, and the Nd:YAG solid-state laser 3 emits a laser beam that passes through the cylindrical light-guiding cavity 9 through the reflection of the mirror 2 and the focusing of the focu...

Embodiment 2

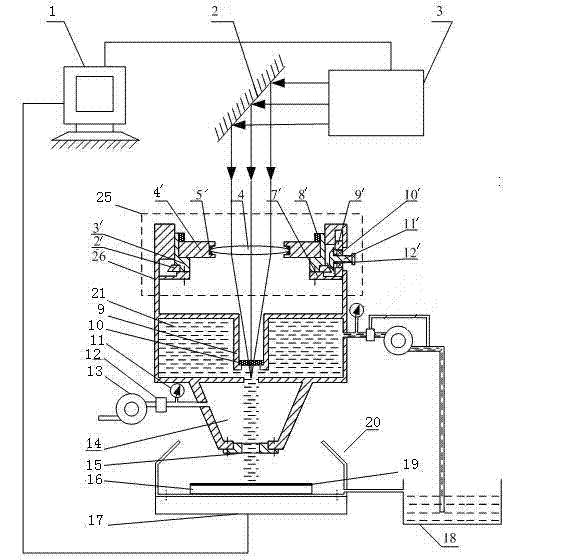

[0049] Such as figure 1 , 4 shown.

[0050] A device for shot-peening the surface of a metal component using a light-water complex, which includes a computer control system 1, a Nd:YAG solid-state laser 3, a mirror 2, a five-axis linkage numerical control work platform 17, a focusing lens focusing system 25, Water storage chamber 21, high pressure resistant glass 10, hydraulic pump 22, high pressure air chamber 14, air pressure pump 13 and nozzle 15; focusing lens focusing system 25 is installed on the top of water storage chamber 21, and it can adopt figure 1 The focusing device shown can also be used Figure 4 The focusing device shown, figure 1 The focus lens focusing system 25 shown includes a moving sleeve 7, a lock nut 8, a focus lens holding ring 6, a washer 5, and a focus lens 4. The focus lens 4 is placed on the focus lens holding ring 6, and the washer 5 will It is fixed, the focus lens clamping ring 6 is in interference fit with the moving sleeve 7, and the movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com