Combination method and apparatus for laser shock processing of engine blade

A technology of engine blades and laser shock, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of reduced processing efficiency, fatigue fracture, large blades, etc., and achieve the effects of avoiding fatigue fracture, improving fatigue life, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better illustrate the implementation details of the present invention, a combined process and device for laser shock treatment of engine blades according to the present invention will be described in detail below in conjunction with the accompanying drawings.

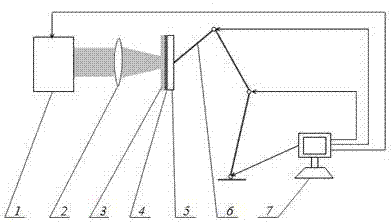

[0016] A combined process device for laser shock treatment of engine blades of the present invention is composed of a laser generator 1 , a focusing lens 2 , deionized water 3 , aluminum foil 4 , engine blades 5 , a six-degree-of-freedom manipulator 6 and a control system 7 .

[0017] The aluminum foil 4 in the combined process device for laser shock treatment of engine blades is pasted on the surface of the engine blade 5 to be treated; the deionized water 3 is covered on the aluminum foil 4; the engine blade 5 is clamped on the six-degree-of-freedom manipulator 6; The control system 7 is connected with the six-degree-of-freedom manipulator 6 and the laser generator 1 respectively.

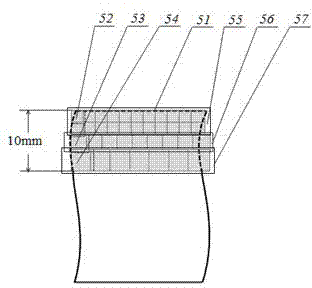

[0018] The mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com