Sheet material double face precise forming method and apparatus based on laser blast wave effect

A technology of laser shock and precision forming, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems that it is difficult to complete the impact forming of complex workpieces, cannot be corrected, and the forming efficiency is low, so as to achieve large curvature local Fully plastic forming of micro-sheets, flexible three-dimensional impact, and the effect of three-dimensional impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

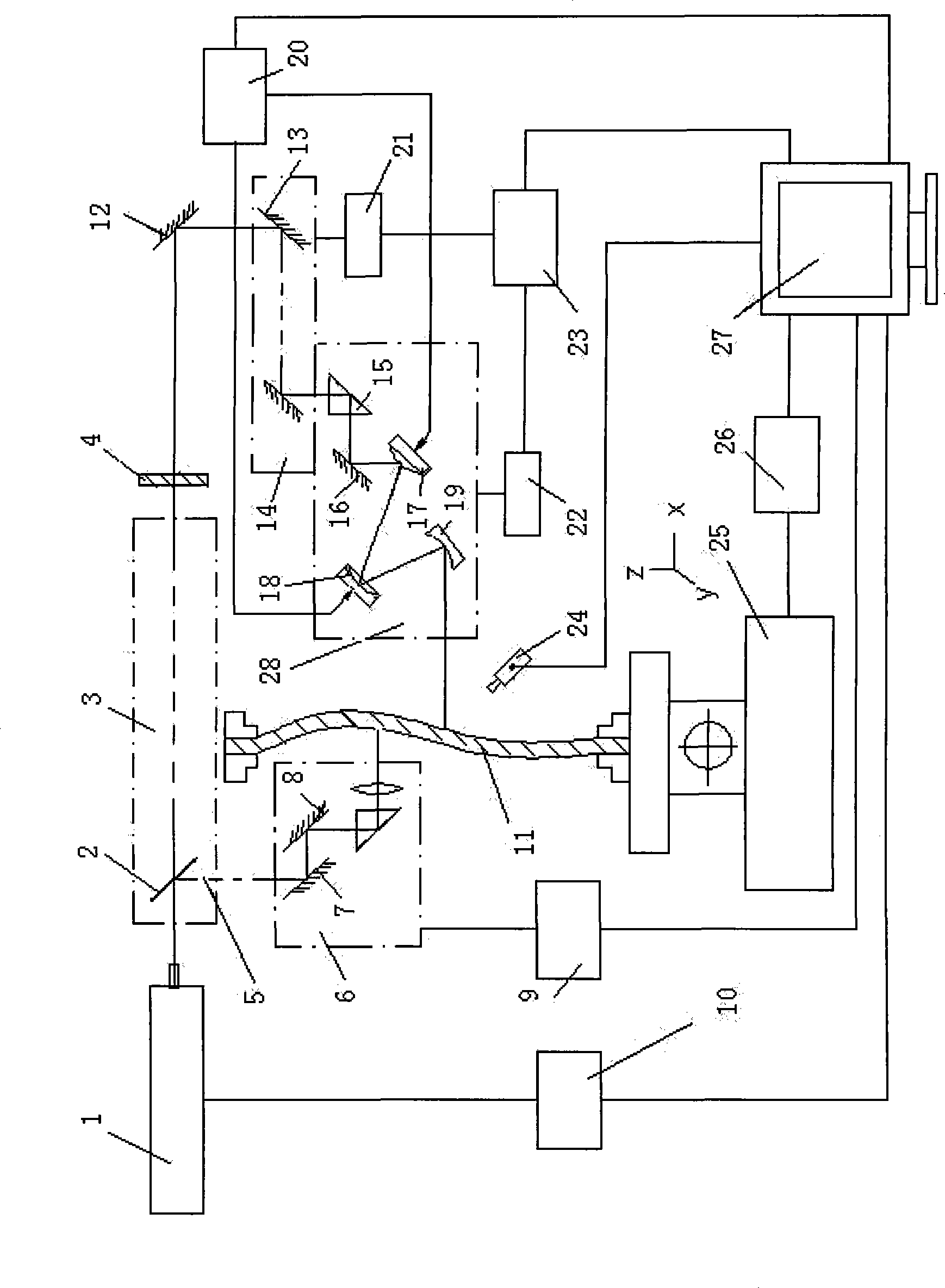

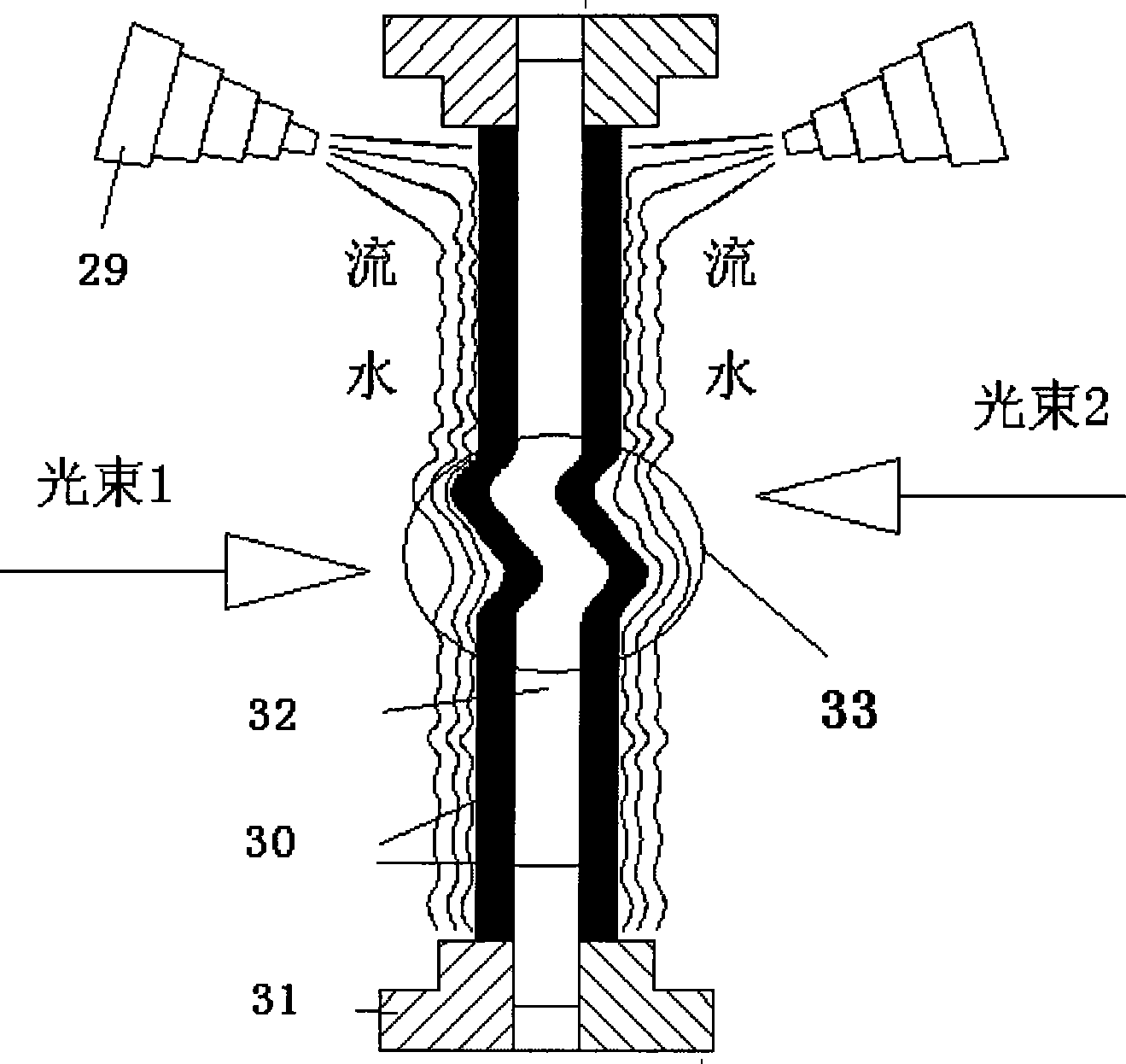

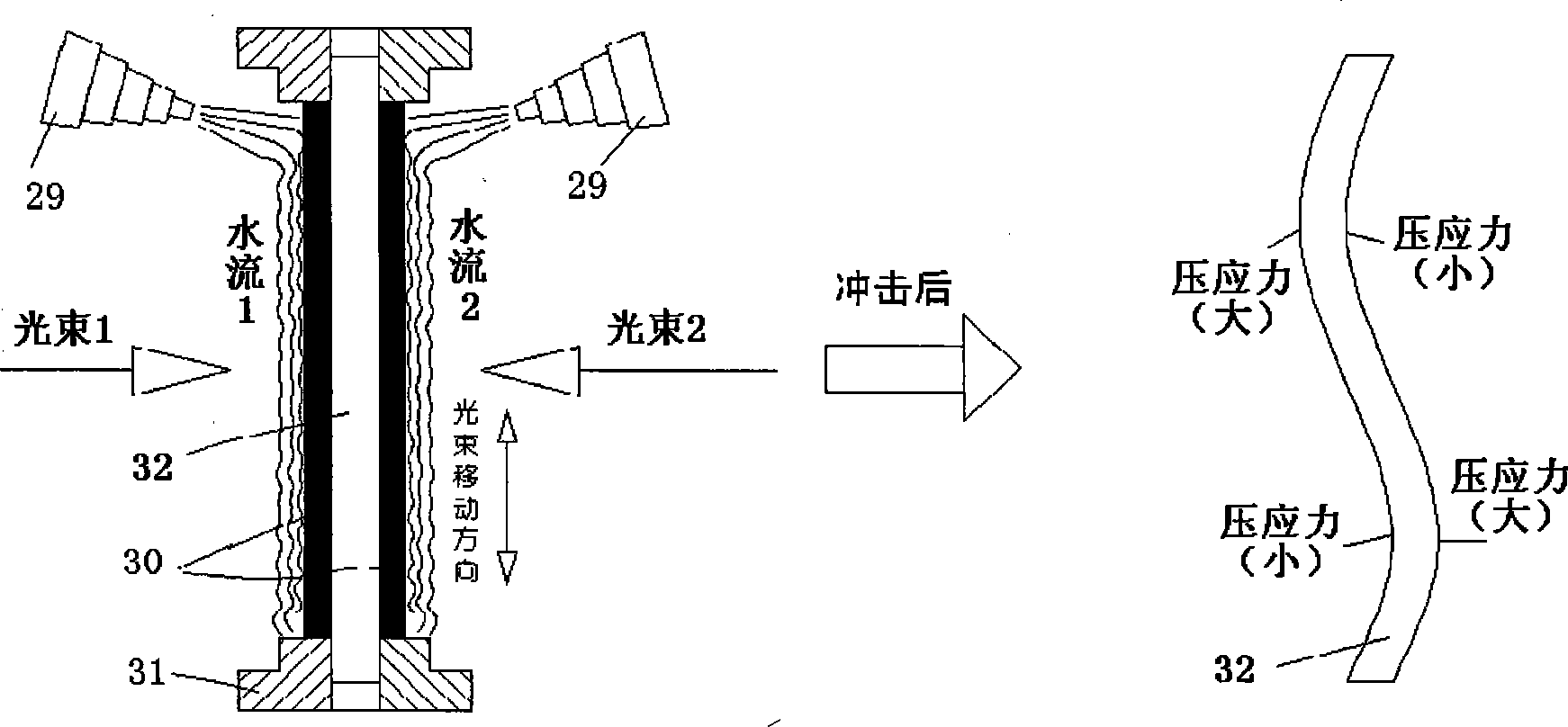

[0032] Combine below figure 1 , figure 2 Describe in detail the details and working conditions of the specific device proposed by the present invention.

[0033] figure 1 As shown, the laser shock double-sided precision forming device includes a laser (1), an external optical path system (3, 5), a laser shock head system A, B (6, 28), a sample system (11), and a detection feedback System (24), multi-axis linkage machine tool and fixture system (25), central control processor (27), control system (9, 10, 20, 23, 26), characterized in that the laser (1) passes through the external optical path system (3,5), respectively connected to the laser impact head system A, B (6, 28), then the laser acts on the sample system (11), and the detection feedback system (24) is controlled by the central control processor (27) The systems (9, 10, 20, 23, 26) are connected, and the sample system (11) is located on the multi-axis linkage machine tool and the fixture system (25).

[0034] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Laser pulse width | aaaaa | aaaaa |

| Beam diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com