Film sticking device for PVC plates

A film sticking device and plate technology, which is applied in the field of PVC plate film sticking devices, can solve the problems of PVC plate crushing, stripping, low efficiency of plate film sticking, etc., and achieve the effects of reducing labor intensity, improving efficiency and effect, and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

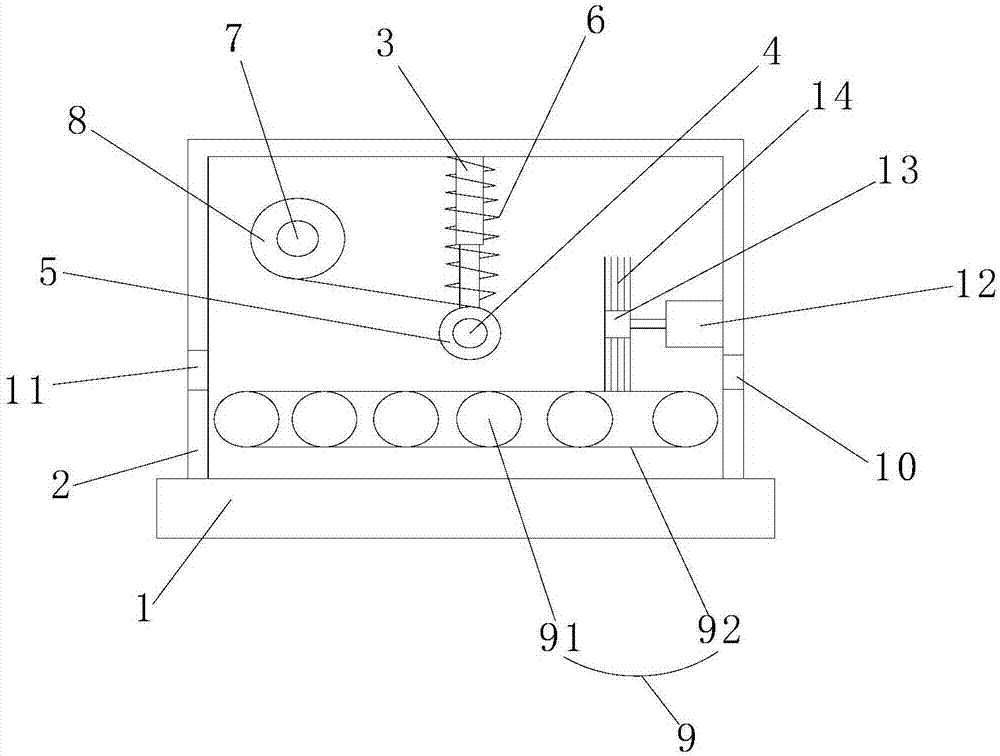

[0012] refer to figure 1 , a PVC plate film sticking device according to the present invention, comprising a base 1, a frame 2, a telescopic rod 3, a traction roller 4, an inflatable sleeve 5, a spring 6, a film roller 7, a film 8, a transmission device 9, a feed port 10, an outlet Feeding mouth 11, motor 12, runner 13 and bristle 14, the top of described base 1 is provided with frame 2, and the bottom of the transverse portion of described frame 2 is fixedly provided with vertical telescoping rod 3, and described telescopic The lower end of the rod 3 rotates and is provided with a traction roller 4 with the central axis facing the front. The circumferential surface of the traction roller 4 is fixedly provided with an inflatable sleeve 5, and the outer side of the telescopic rod 3 is provided with a spring 6. The traction roller The top right of 4 is rotated and provided with a film roll 7 whose central axis is facing the front. The side is provided with feed port 10, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com