Continuous online coating and coiling process for color-coated steel coils

A color coating, steel coil technology, applied in the direction of winding strips, packaging, thin material processing, etc., can solve the problems of prone to heart roll, prone to collapse, film deformation, etc., to achieve good film effect and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The color-coated steel strip is sent through the conveyor belt to be pasted by the cold film, (strip width 1200mm, film thickness 0.06mm, film width 1202mm) the machine controls the pressure of the film roller on the cold film laminating machine at 9N / mm, and controls the film tension at 300- 400 Newtons, the pressure sensor is used to detect the film tension online in real time, and the information is sent to the tension controller. The tension controller converts, compares and judges the information, and then outputs the control signal to the core with the cold film roll on the cold film decoiler. The electronic braking device on the shaft controls the rotation speed of the mandrel (with cold film roll) through the electronic braking device. After testing, the film sticking effect is good, smooth and free of bubbles, and there is no deformation and wrinkle on the film surface.

Embodiment 2

[0031] Send the color-coated steel strip through the conveyor belt to the cold film laminating machine for film lamination (strip width 1100mm, film thickness 0.04mm, film width 1106mm), control the pressure of the film laminating roller on the cold film laminating machine at 11N / mm, and control the film tension at 60- 100 Newton, all the other are with embodiment 1. After testing, the film sticking effect is good, and there is no deformation and wrinkle on the film surface.

Embodiment 3

[0033] Send the color-coated steel strip through the conveyor belt to the cold film laminating machine for film lamination (strip width 1200mm, film thickness 0.08mm, film width 1204mm), control the pressure of the film laminating roller on the cold film laminating machine at 10N / mm, and control the film tension at 500- 600 Newton, all the other are with embodiment 1. After testing, the effect of the film is good, smooth and free of bubbles, and the film has no deformation and wrinkle problems.

[0034] Coiling Example

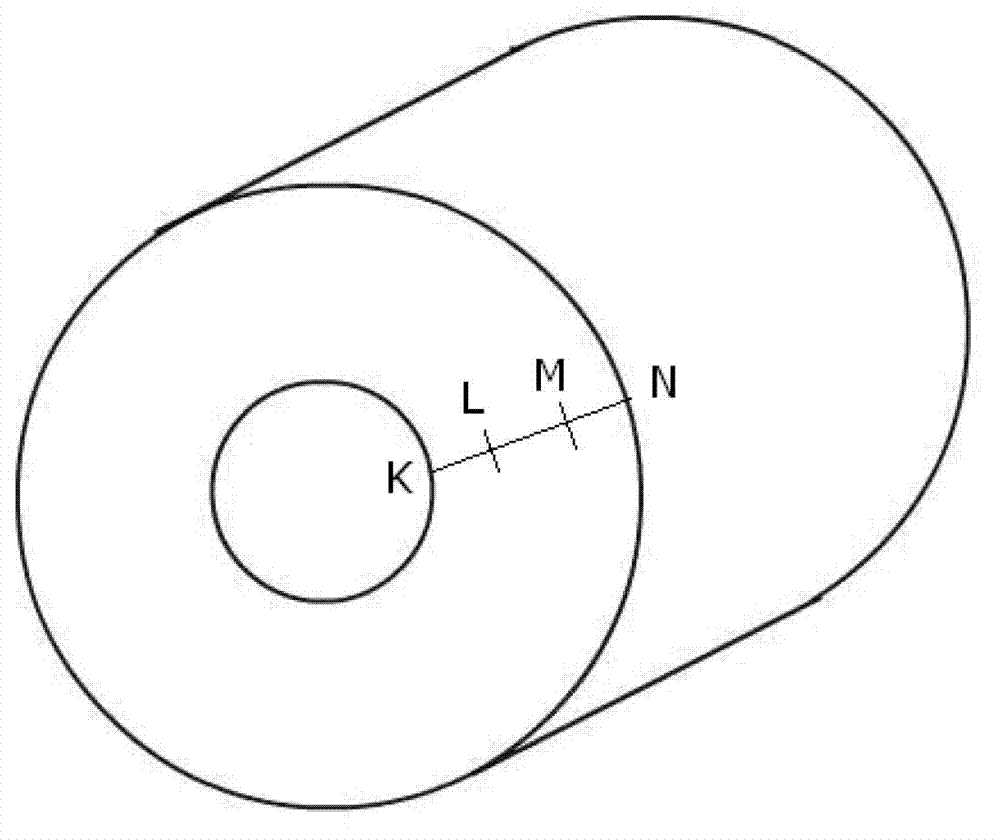

[0035] The color-coated steel strip after the cold film coating in Example 1 is sent to the coiler through the feeding roller to be coiled into a color-coated steel coil, and the specific parameters are controlled according to the different thicknesses of the steel strip as follows (wherein, refer to figure 1 , within 10cm of the inner circle is indicated as the distance of K-L, within 10-20cm of the inner circle is indicated as the distance of L-M, and if th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com