Touch screen laminating equipment

A technology of laminating equipment and touch screen, applied in the directions of external support, transportation and packaging, winding strips, etc., can solve the problems of unstable attachment effect, offset size of lamination, low work efficiency, etc., and achieve good filming effect, Guarantee the film position and increase the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

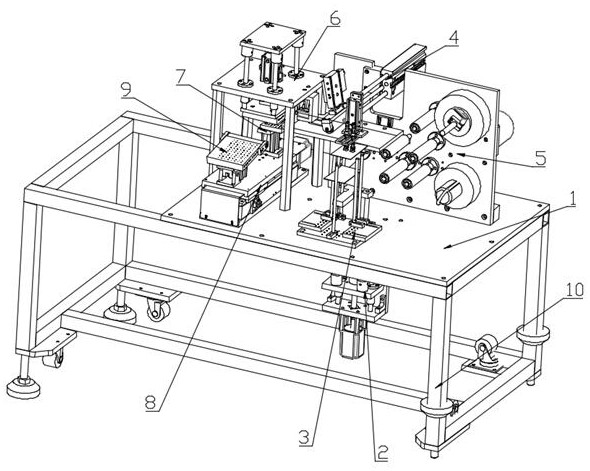

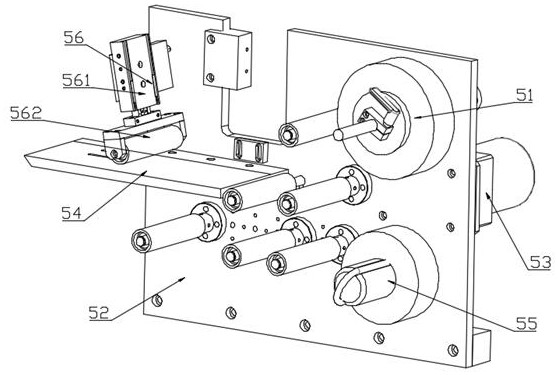

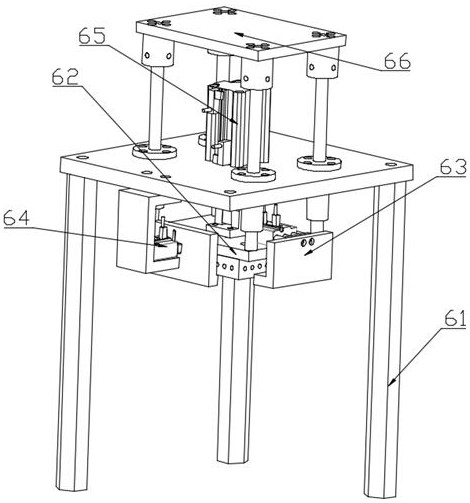

[0031] Such as figure 1 As shown, Embodiment 1 of the present invention: a touch screen bonding equipment, including a frame 10, a bottom plate 1, a feeding mechanism 2, a feeding auxiliary assembly 3, a retrieving mechanism 4, a film conveying mechanism 5, and a correction and pressing mechanism 6 , a hot compress mechanism 7, a longitudinal conveying mechanism 8 and a smoothing mechanism 9, the bottom plate 1 is arranged on the upper part of the frame 10, the film coating conveying mechanism 5 is arranged transversely on the right end rear side of the bottom plate 1, the The feeding mechanism 4 is longitudinally arranged on the top of the film conveying mechanism 5, the feeding auxiliary assembly 3 is arranged on the right front side of the bottom plate 1, and the feeding mechanism 2 is arranged on the right front back of the bottom plate 1 , and pass through the bottom plate 1 upwards and are located at the lower part of the auxiliary feeding assembly 3, the longitudinal co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com