Method for improving corrosion resistance of ZL303 aluminum alloy film

A ZL303, corrosion resistance technology, applied in the field of improving the corrosion resistance of the ZL303 aluminum alloy film layer, can solve the problems of ZL303 aluminum alloy micro-arc oxidation without research, achieve high thickness and hardness, improve corrosion resistance, and increase thickness and the effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

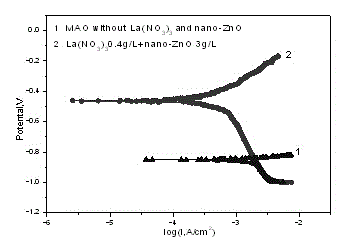

Image

Examples

Embodiment

[0016] The experiment uses ZL303 aluminum alloy as the base material. Prepare Na 2 Si0 3 Basic electrolyte, which consists of Na 2 Si0 3 10g / L,Na 2 WO 4 2g / L, NaOH 2g / L, H 2 0 2 4 ml / L, and then add ZnO to the corresponding electrolyte in a certain proportion. The amount of ZnO added is shown in Table 1.

[0017] Table 1 List of samples of mixed additives

[0018] Sample serial number Nano ZnO additive content (g / L) 0 # 0 1 # 2 2 # 3 3 # 4 4 # 2 5 # 3 6 # 4 7 # 2 8 # 3 9 # 4

[0019] The experiment was carried out by self-made double-pulse micro-arc oxidation equipment. The experimental voltage is 550V, the time is 50 minutes, the frequency is 400Hz, and the duty cycle is 30%. During the experiment, the temperature of the solution was kept at about 30°C.

[0020] Measure the average thickness of the ceramic layer with a TT230 cladding thickness gauge: measure the thickness of 5 points on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com