Wafer laminating device

A film sticking device and wafer technology, applied in transportation and packaging, conveyor objects, electrical components, etc., can solve the problems of film size smaller than wafer, material waste, etc., to achieve improved film sticking effect, wide application range, and strong adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

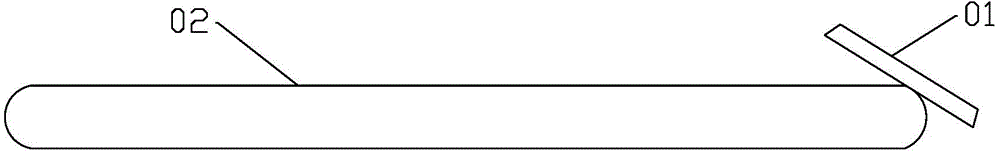

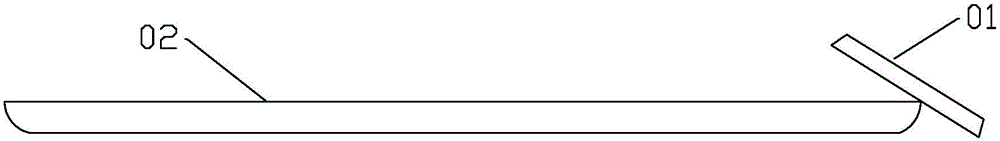

Image

Examples

Embodiment 1

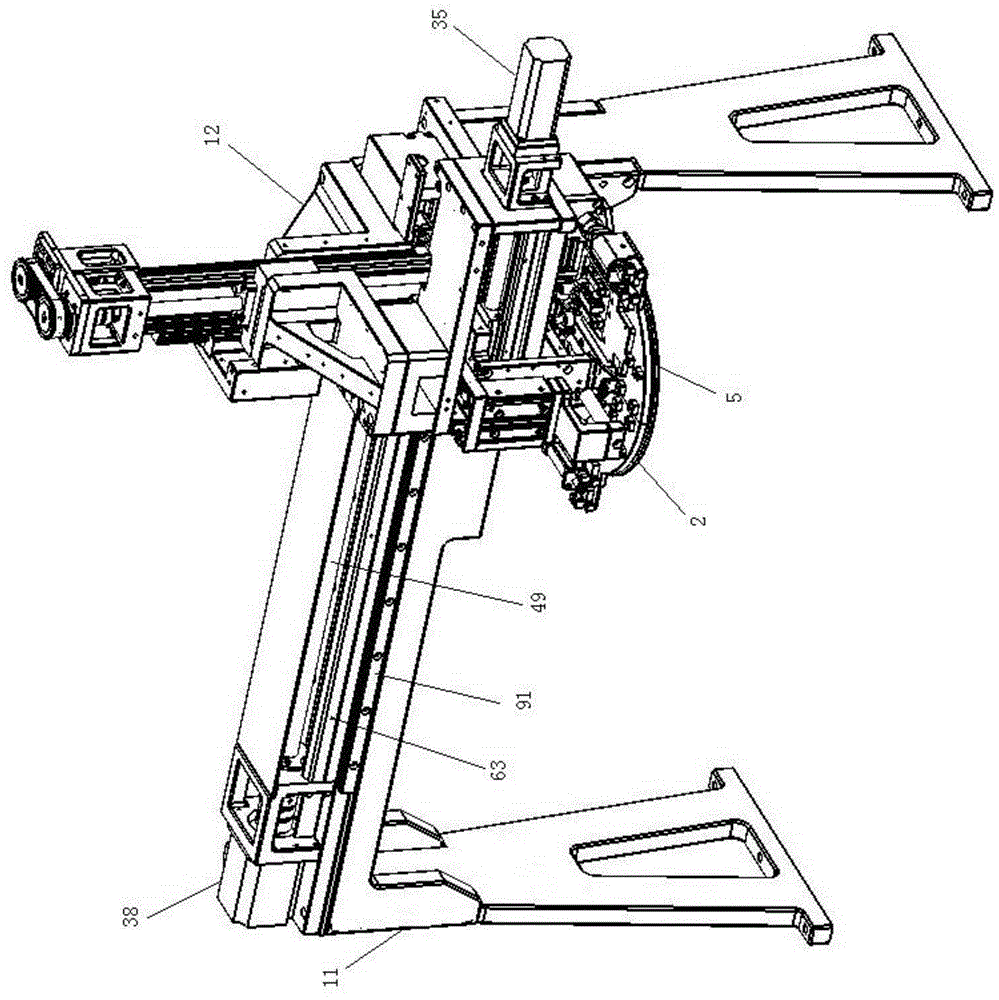

[0054] Such as Figure 3-13 As shown, the wafer attaching device includes a support frame 11 and a support arm 12 . The support arm 12 is mounted on the support frame 11 so as to move left and right. A first bracket 13 is also included, and the first bracket 13 is installed on the support arm 12 in a liftable manner. A second bracket 14 is also included, and the second bracket 14 is mounted on the first bracket 13 so that it can move left and right.

[0055] The wafer attaching device also includes a first fixing device 2 . The first fixing device 2 includes a first adsorption plate 21 . The first adsorption plate 21 is reversibly mounted on the first bracket 13 via the first rotating shaft 22 . The first adsorption plate 21 tilts after turning over. A first driving device is installed on the first support 13 , and the first driving device is a first air cylinder 31 . The first cylinder 31 drives the first adsorption plate 21 to turn over through the first transmission d...

Embodiment 2

[0084] Different from Embodiment 1, the wafer attaching device in this embodiment does not include the first clamping plate 23 and the second clamping plate 53, and only absorbs the film through the first adsorption plate 21 and the second adsorption plate 51, and also It can achieve the clamping function of the film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com