Full-automatic efficient glass film sticking machine

A glass laminating, fully automatic technology, applied in the field of automatic high-efficiency glass laminating machine, can solve the problems of complex structure and huge volume, and achieve the effect of small size, small occupied area, fully automatic and efficient laminating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

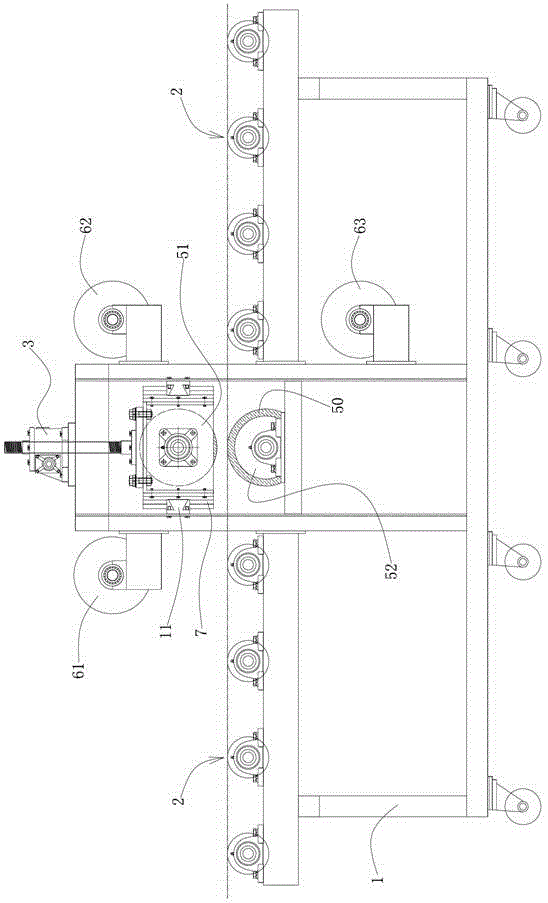

[0019] like figure 1 As shown, a fully automatic high-efficiency glass film laminating machine includes a frame 1, a conveying roller 2, a film covering roller, a film laminating roller, a lifting drive mechanism 3, and a film cutting mechanism (not shown in the figure).

[0020] The film laminating roller is arranged on the frame 1, and includes a first film laminating roller 51 positioned above the conveying roller 2, and a second film laminating roller 52 positioned below the first film laminating roller 51, the first film laminating roller 51 and the second film laminating roller 52 is provided with a rubber sleeve 50, which is used to draw and paste the film on the sleeve roll to the glass surface conveyed by the transfer roll.

[0021] The conveying rollers 2 are arranged on the frame 1 and include a plurality of conveying rollers located on the left and right sides of the first laminating roller 51 for conveying the glass to be laminated from left to right or from right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com