Film sticking method and equipment

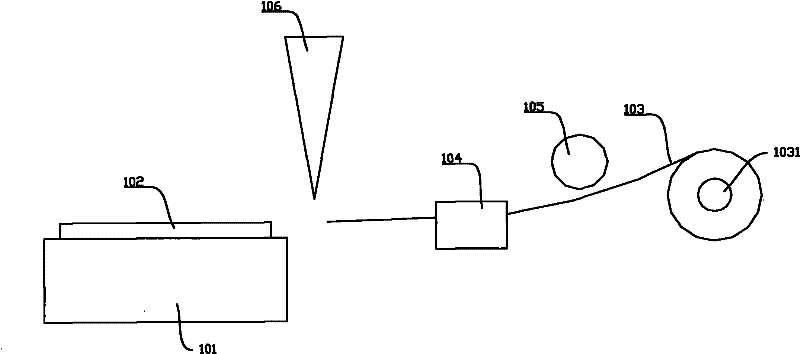

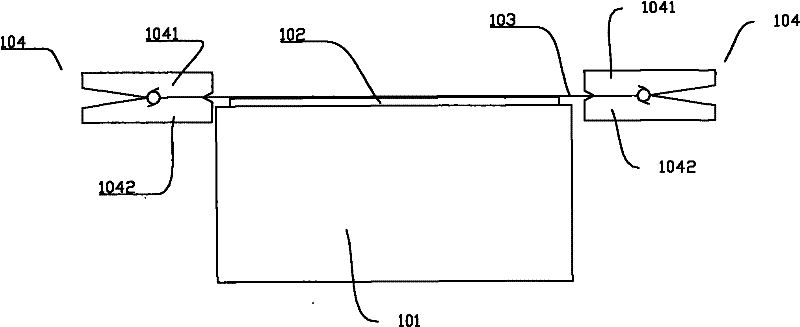

A film sticking equipment and film sticking technology, applied in the fields of electrical components, packaging, semiconductor/solid-state device manufacturing, etc., can solve problems such as the inability to clamp the film 103 smoothly, direct stretching or shrinking of the wafer, waste in the width direction, etc., to achieve deformation Small size, save film, improve film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the drawings:

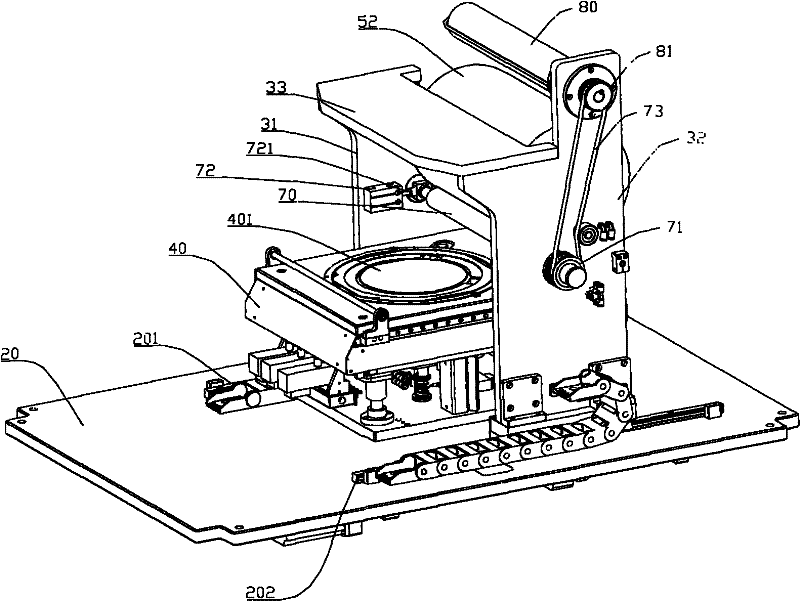

[0047] Such as image 3 , Figure 4 , Figure 5 As shown, the film sticking device includes a base plate 20. Two parallel guide rails (201, 202) are provided on the upper surface of the base plate 20.

[0048] The bracket plate 31 and the bracket plate 32 are arranged on the base plate 20 in parallel. Two sliding blocks 311 are installed at the bottom of the support plate 31. The two sliding blocks 311 are respectively provided with grooves (not shown in the figure) to cooperate with the guide rail 201, so that the support plate 31 can only move along the guide rail 201 when it moves. The mounting method of the support plate 32 is the same as that of the support plate 31. The upper ends of the support plate 31 and the support plate 32 are both connected with the cover plate 33. The bracket plate 31, the bracket plate 32 and the cover plate 33 form a movable gantry.

[0049] A guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com