Coating device of automotive interior part

A technology for automotive interior parts and film sticking equipment, which is applied to lamination devices, lamination auxiliary operations, lamination, etc., can solve problems such as difficult gas removal, protective film peeling off, and large bubbles, so as to increase speed and The quality of the film, the effect of improving production efficiency and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below in conjunction with accompanying drawing:

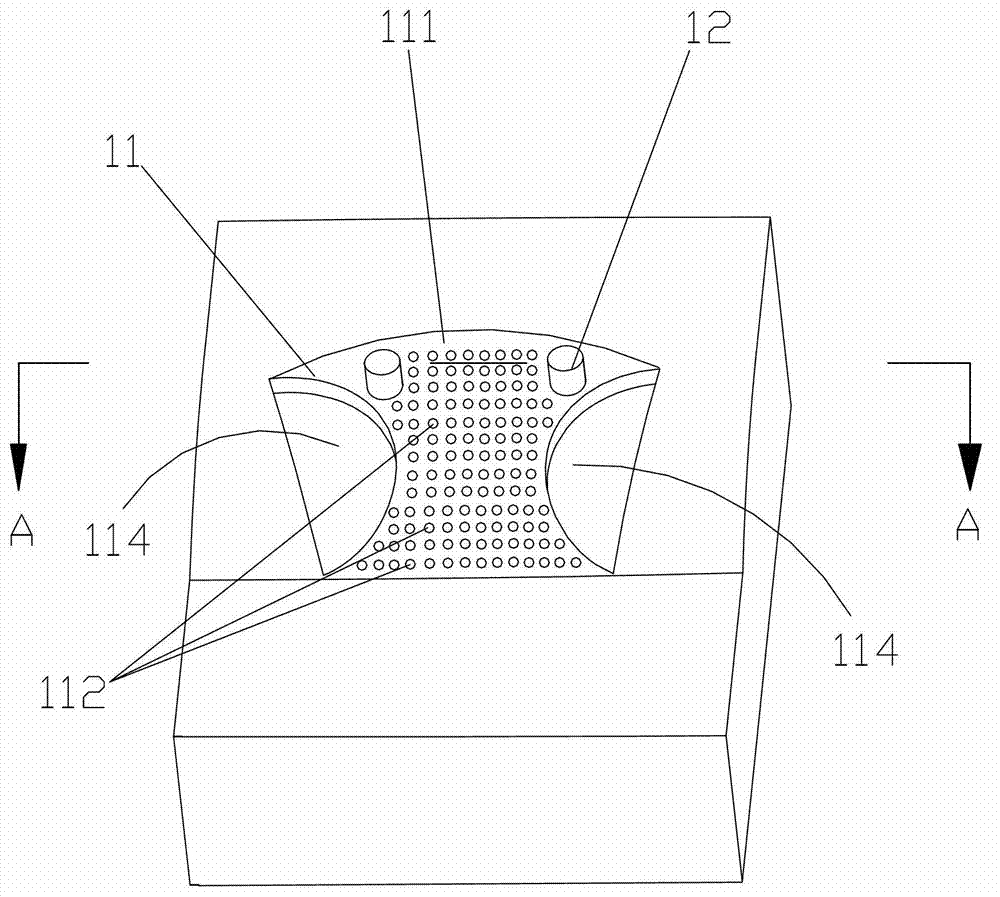

[0028] like figure 1 and figure 2 Shown: the film sticking equipment for automotive interior parts, including a bottom mold assembly 1 and a rolling assembly 2 for placing the film 3 and the automotive interior parts 4 . The bottom mold assembly 1 is used in cooperation with the rolling assembly 2.

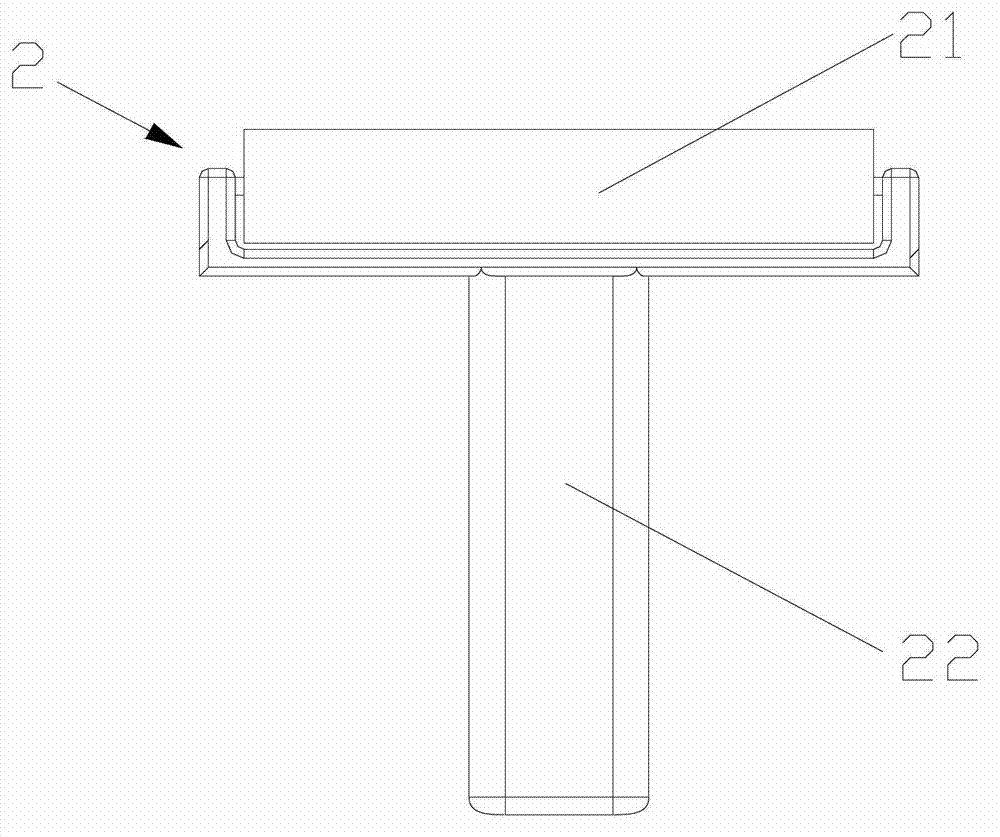

[0029] like figure 1 As shown, the rolling assembly 2 includes a roller 21 and a handle frame 22 , and the roller 21 is rotatably arranged on the handle frame 22 . Handle frame 22 is " T " font.

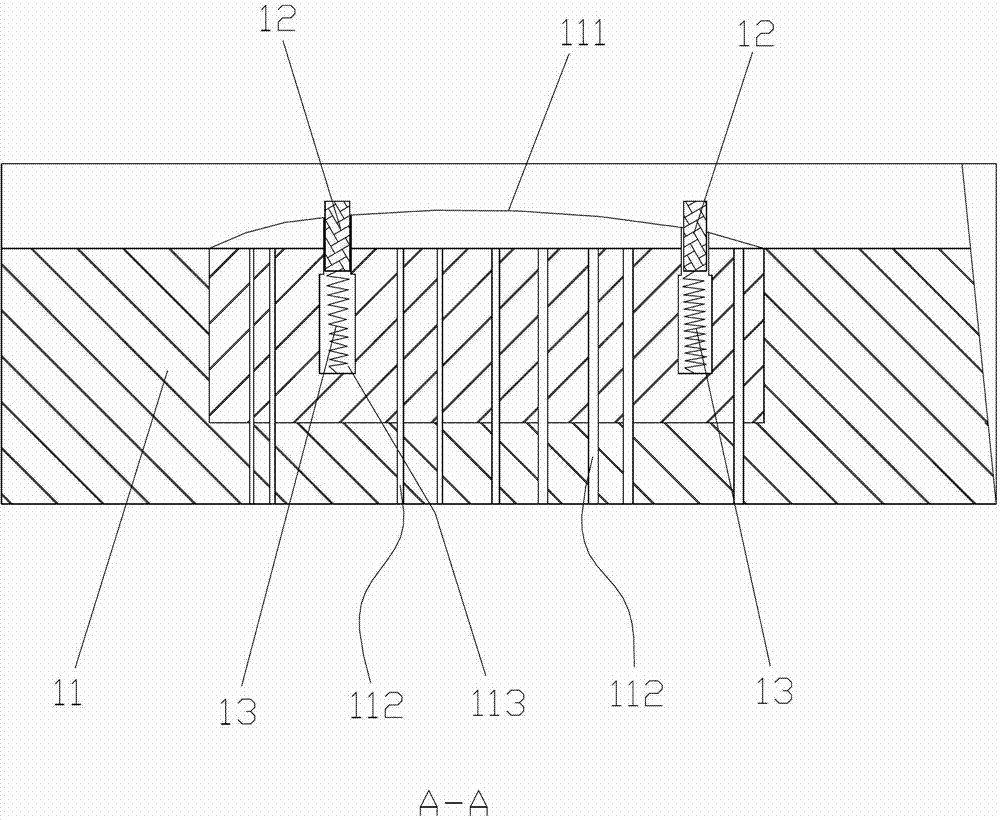

[0030] like figure 2 and image 3 As shown, the bottom mold assembly 1 includes a silicone base 11 , a positioning post 12 and a compression spring 13 . The base 11 has a film-attaching surface 111, and the shape and size of the film-attaching surface 111 are compatible with the film to be attached to the automotive interior part 4. Vent holes 112 are formed through the base 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com