Automatic furniture plate feeding and film pasting system with high machining efficiency

A processing efficiency and automatic feeding technology, which is applied in the field of furniture manufacturing, can solve the problems of slow operation speed, high labor intensity, and low processing efficiency, and achieve the effects of reducing work intensity, improving processing efficiency, and reducing air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

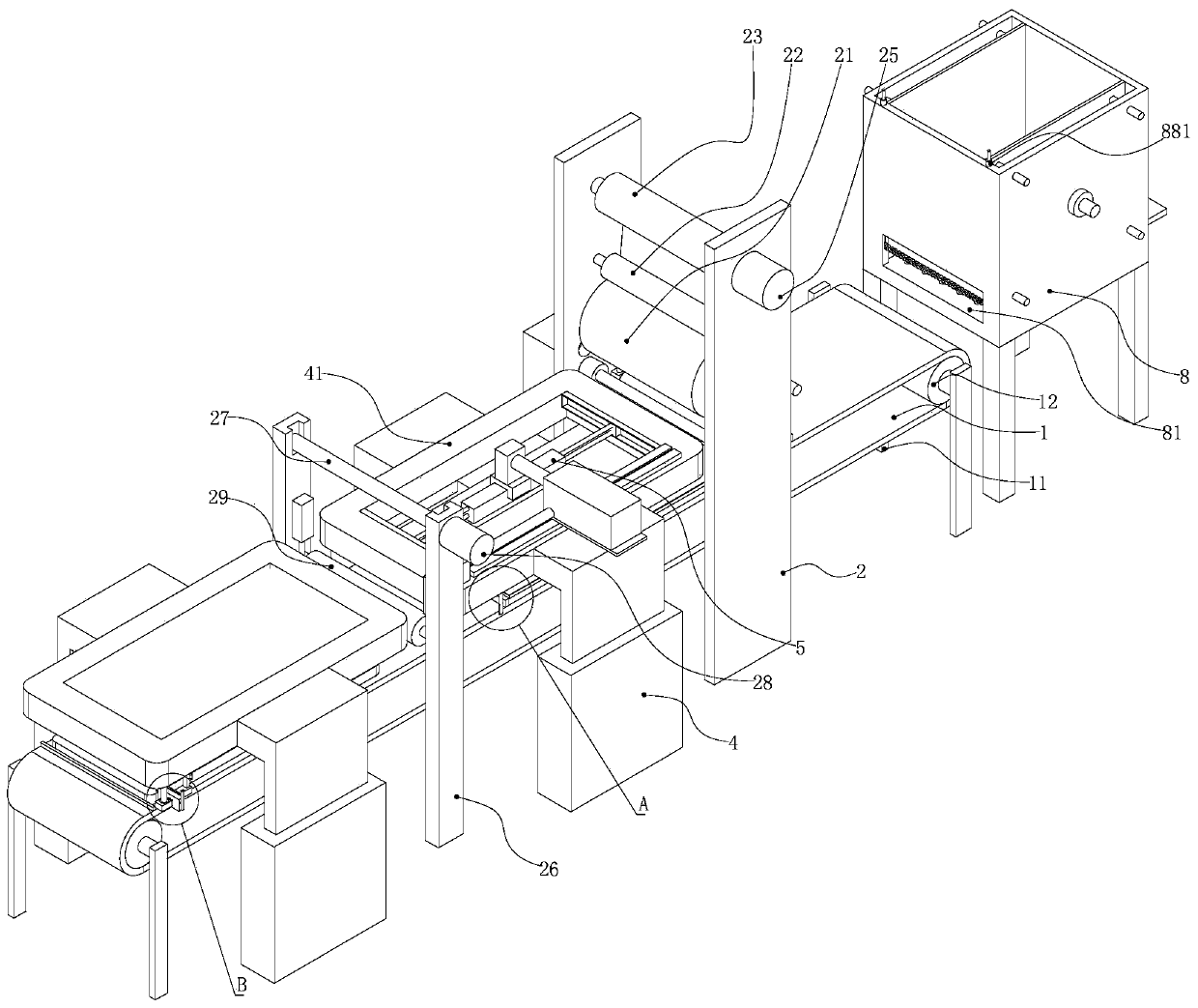

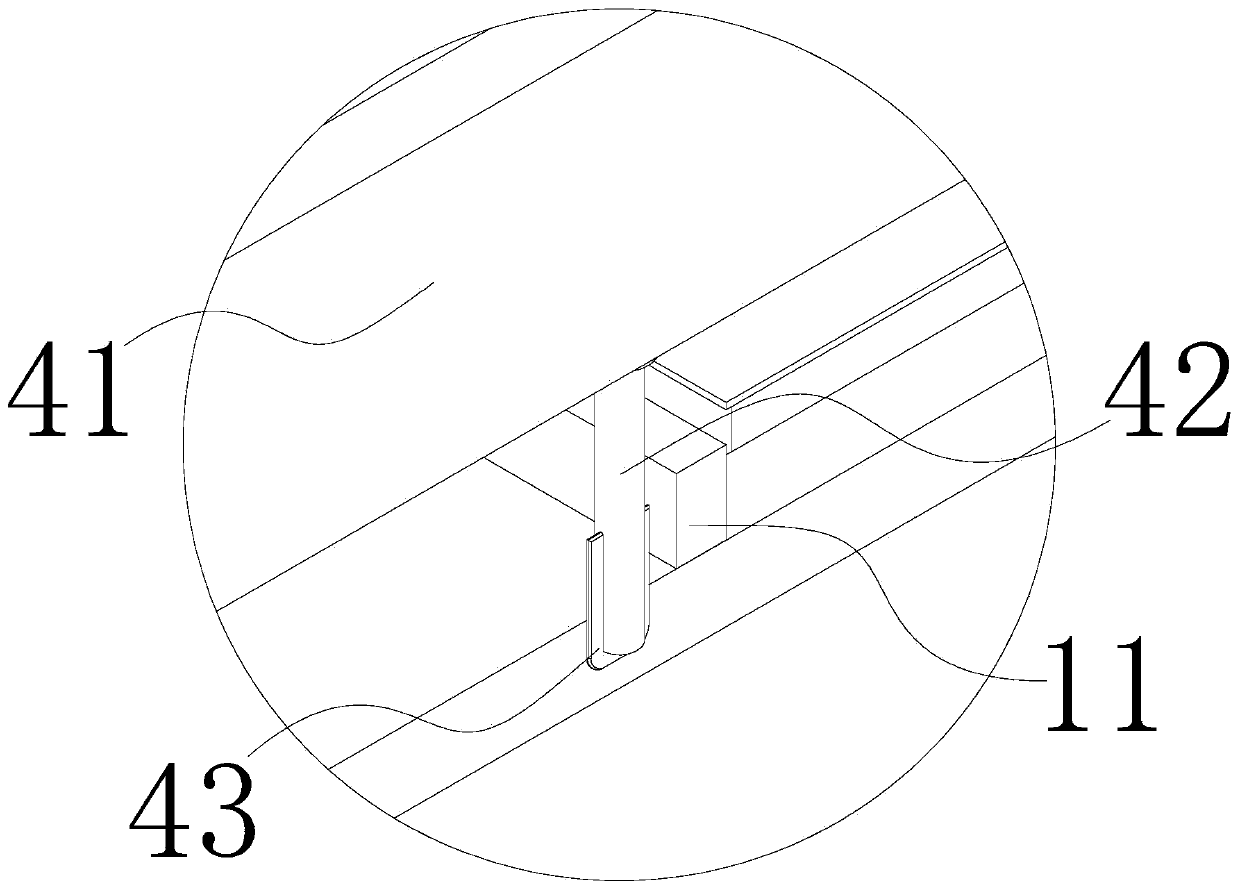

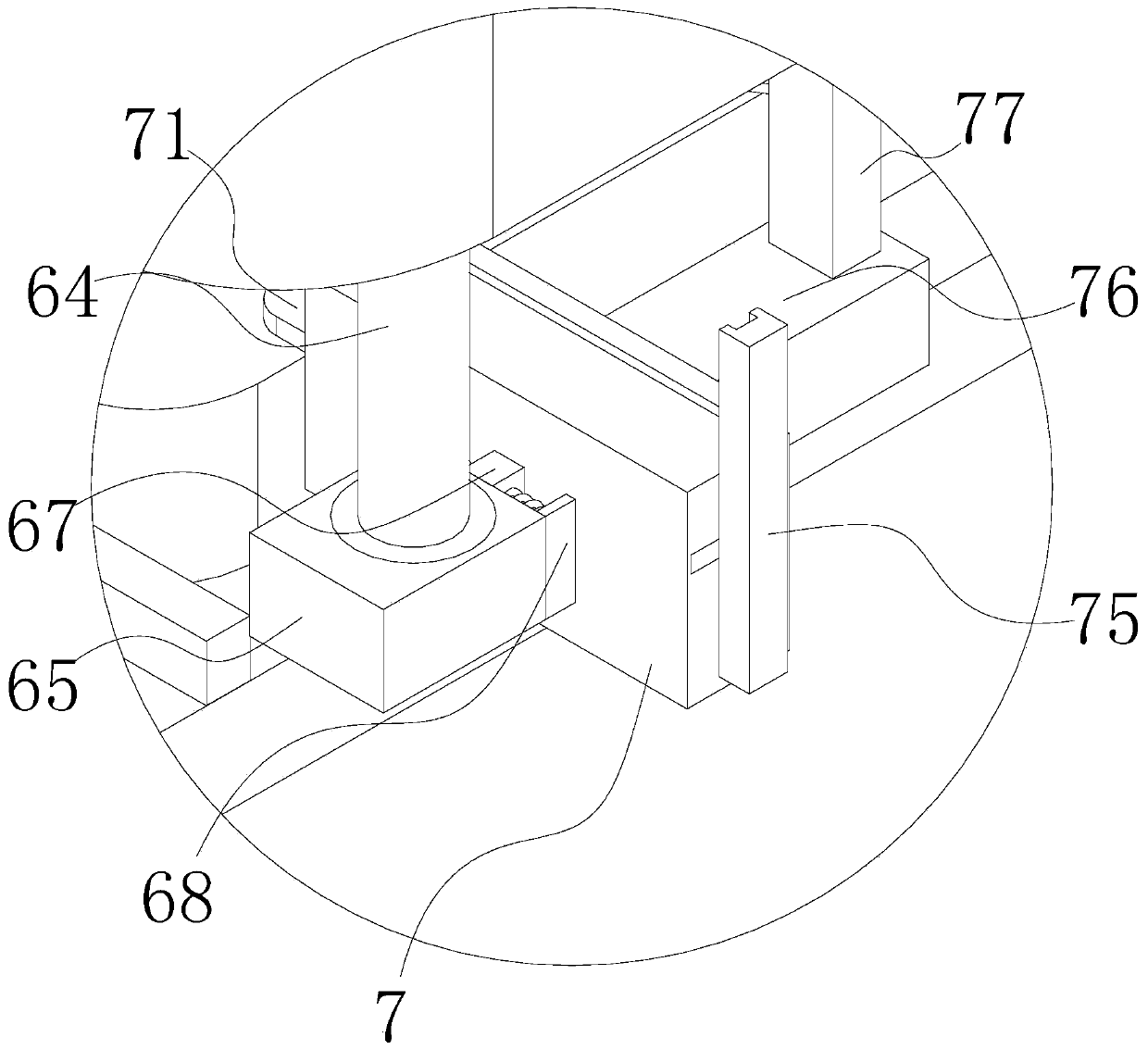

[0024] Such as Figure 1-13 As shown, a furniture board automatic feeding film sticking system with high processing efficiency includes a feeding device, a board conveying device stretching device, an air bubble processing device and a trimming device. The feeding device includes a material storage box 8, a material outlet 81, push plate 82, push plate driver 83, second chute 84, sliding block 85, rotating shaft 86, roller 87, second screw rod 88, second nut 881, insertion slot 89, insertion plate 891, connection Block and adjustment mechanism, the bottom of the storage box 8 is evenly provided with a plurality of balls, by setting the balls can reduce the friction when the push plate moves the plate, and reduce the damage of the plate; the discharge port 81 is opened in the storage box On the wall of the box, the push plate 82 can be inserted into the material storage box, the push plate driver 83 is an air cylinder, and its output end is fixed on the push plate, then the pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com