Locking nut

A technology of locking nut and parent body, applied in the direction of nuts, locking fasteners, screws, etc., can solve the problems of difficulty in tightening and assembling nylon self-locking nuts, shock and vibration of nuts, and difficult access of bolts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

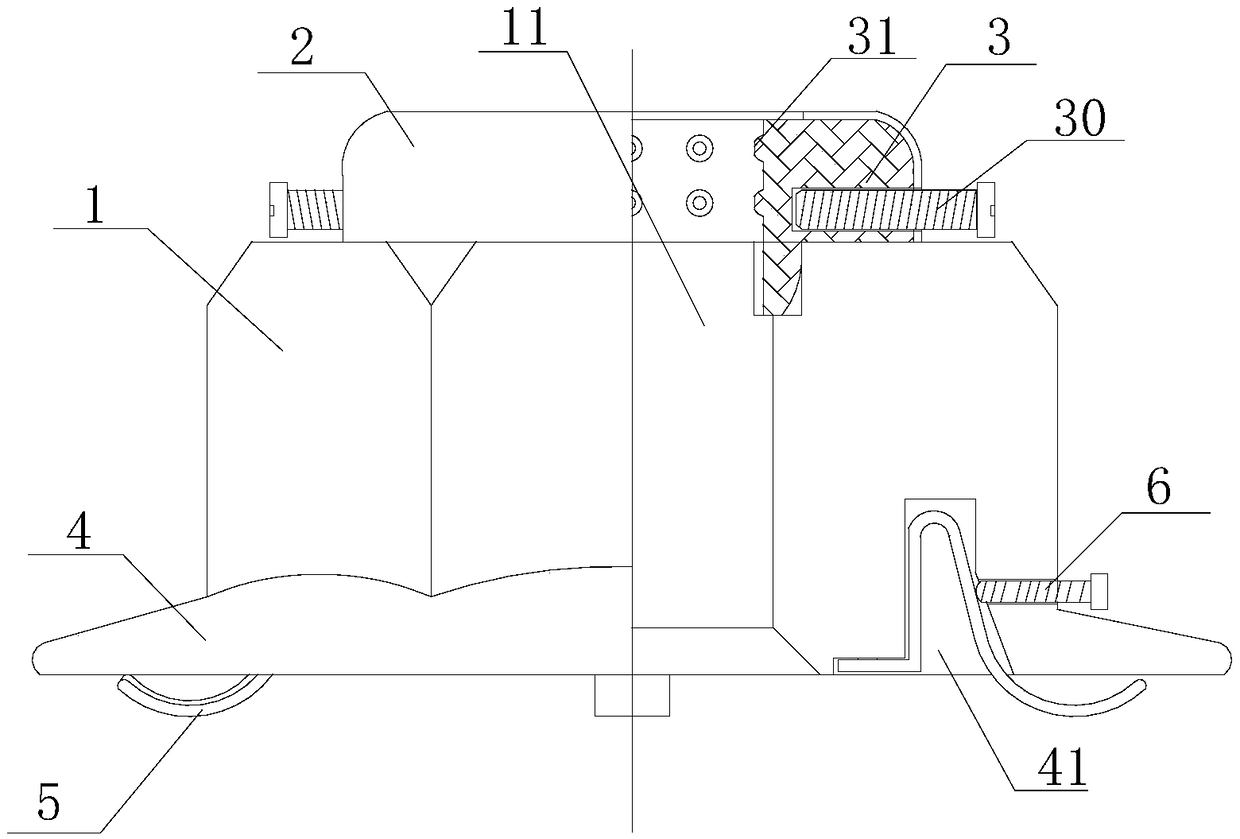

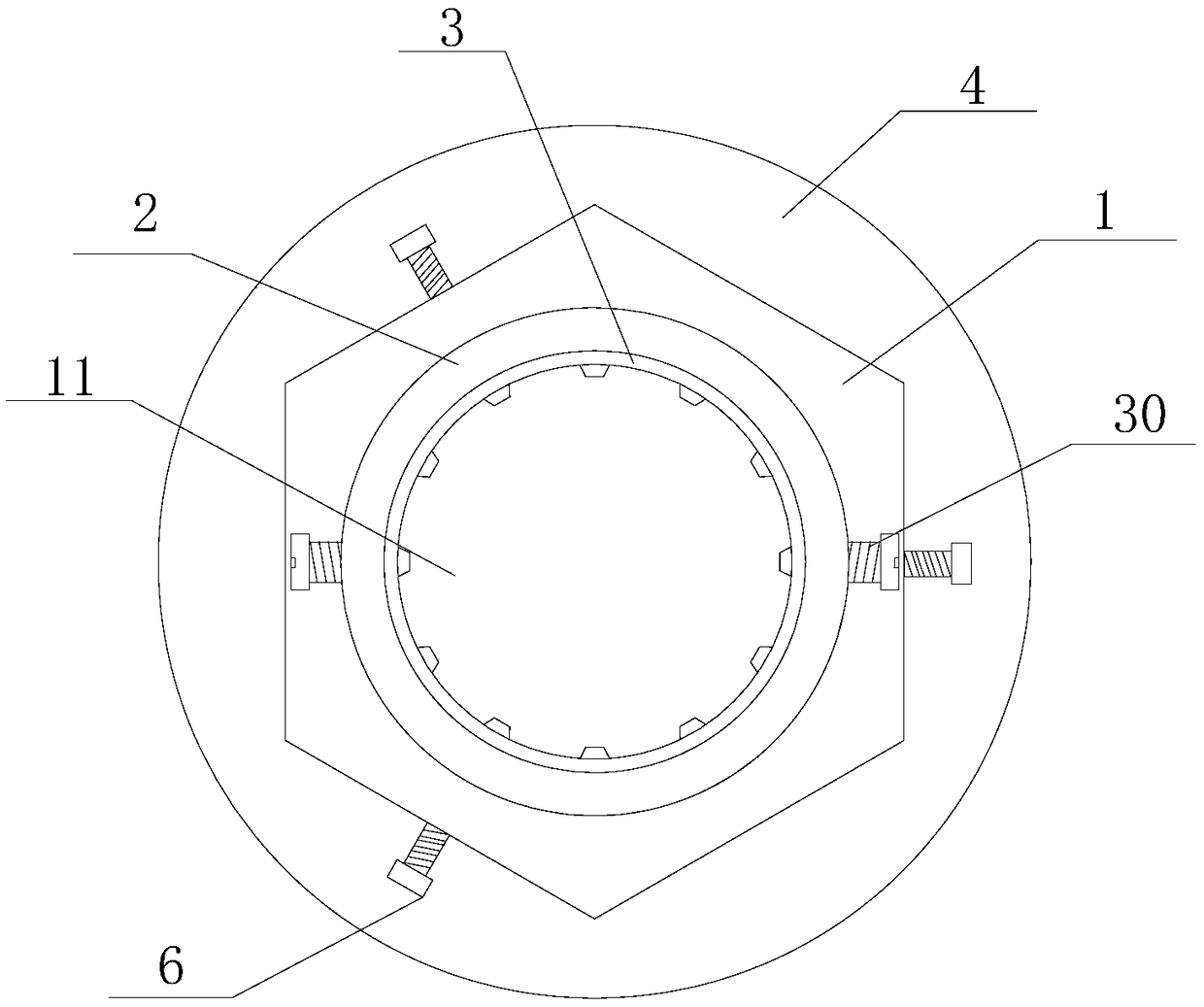

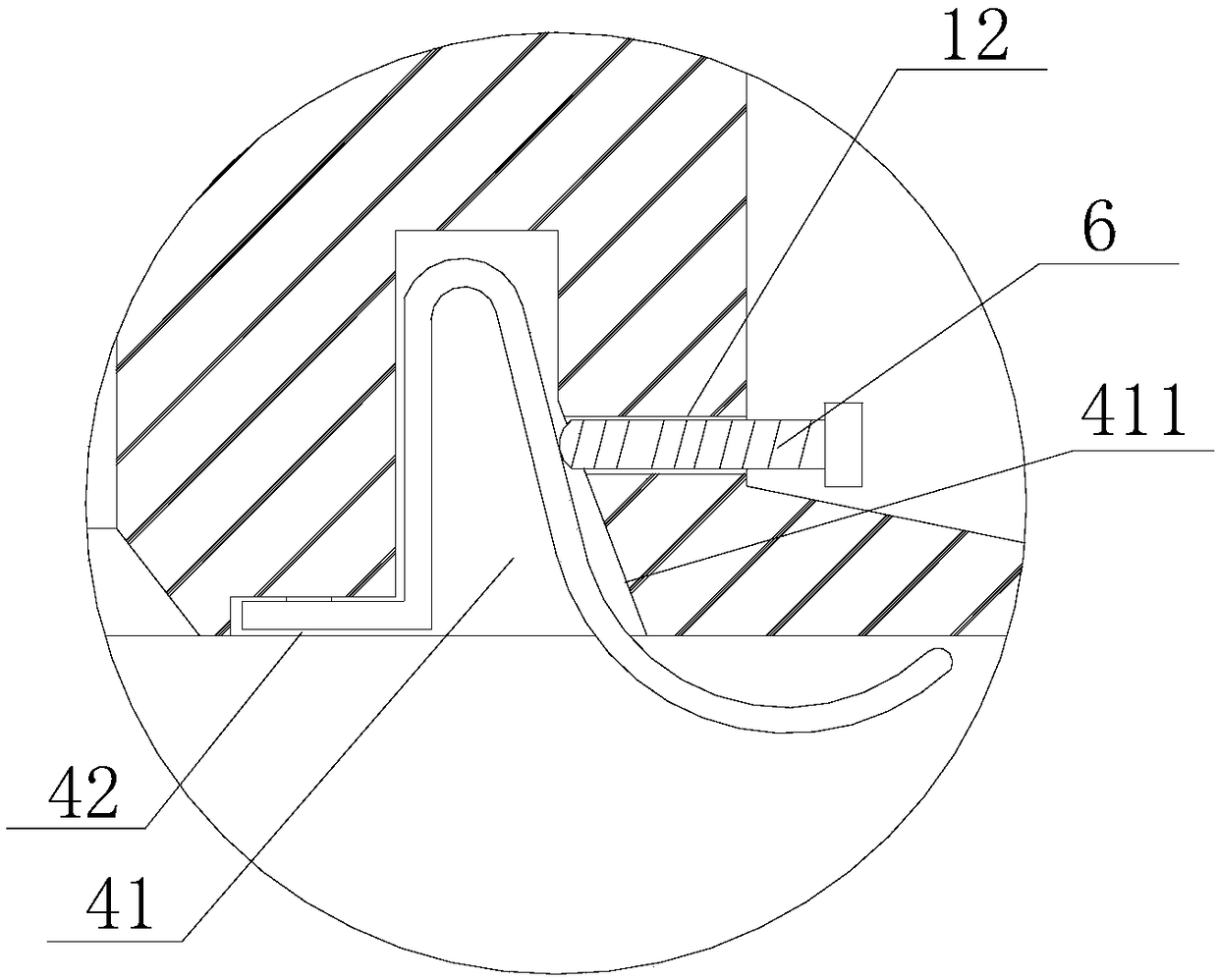

[0017] refer to Figure 1 to Figure 5 , a lock nut according to the present invention is characterized in that: a lock nut is characterized in that it includes a hexagonal nut body 1, an annular boss 2, a nylon ring 3, a flange pad 4, an anti-loose shrapnel 5 and an adjusting screw 6. The upper end surface of the hexagonal nut body 1 is provided with an annular boss 2, and the annular boss 2 is provided with an installation ring groove, and a nylon ring 3 is embedded in the installation ring groove, and the hexagon nut body 1 There is a central threaded hole 11 at the midline of the center line, the axis of the nylon ring 3 coincides with the central threaded hole 11, the lower end surface of the hex nut body 1 is connected with a flange pad 4, and the lower end surface of the flange pad 4 is opened There are several accommodation slots 41 , the anti-loosening shrapnel 5 is installed in the accommodation slots 41 , the adjusting screw 6 is installed on the side wall of the hex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com