Stable clamping driving device used for H-shaped steel

A technology of driving equipment and H-shaped steel, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve problems such as slipping, achieve the effects of solving slipping problems, ensuring stability, and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Now further illustrate how the present invention is implemented in conjunction with accompanying drawings:

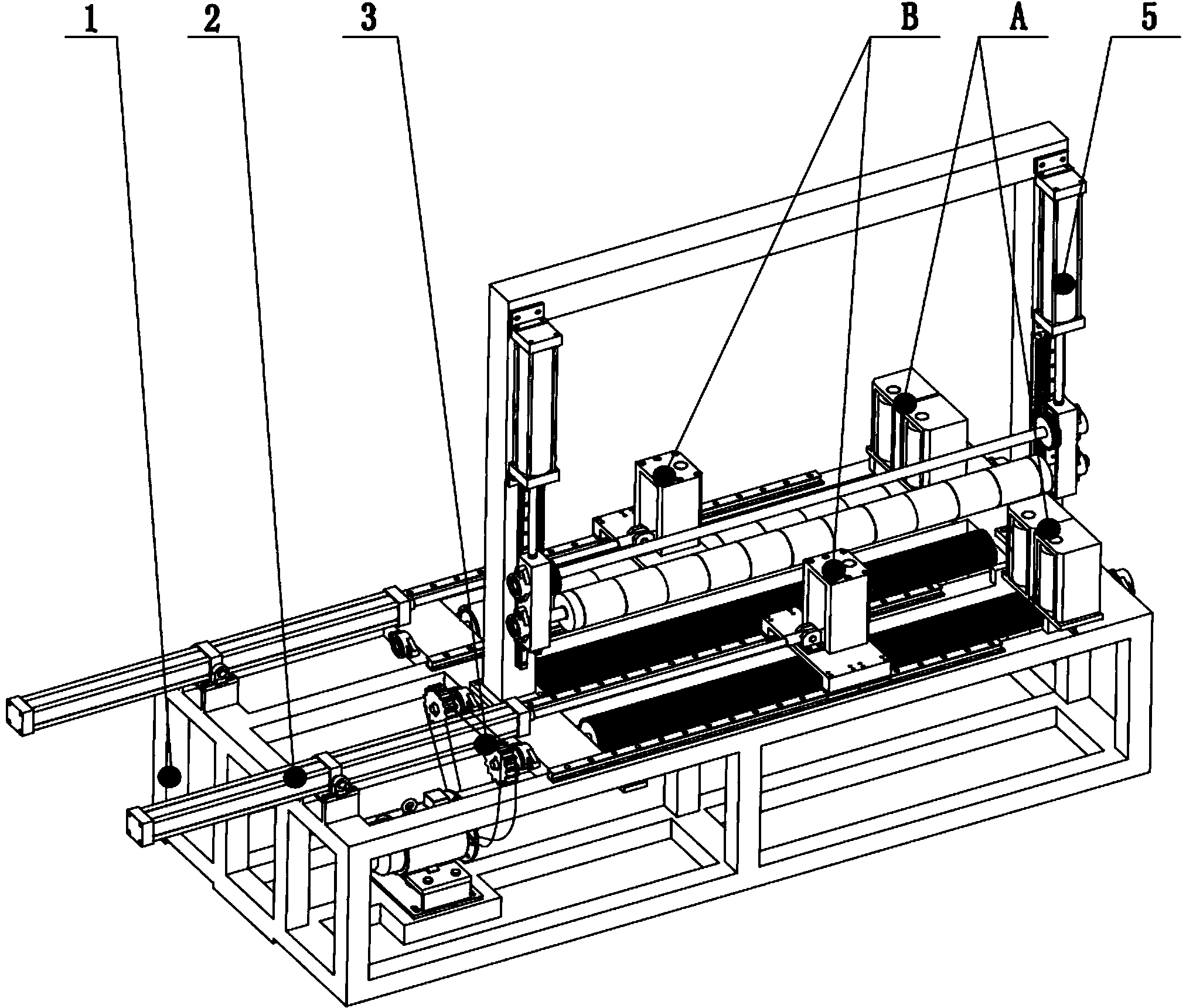

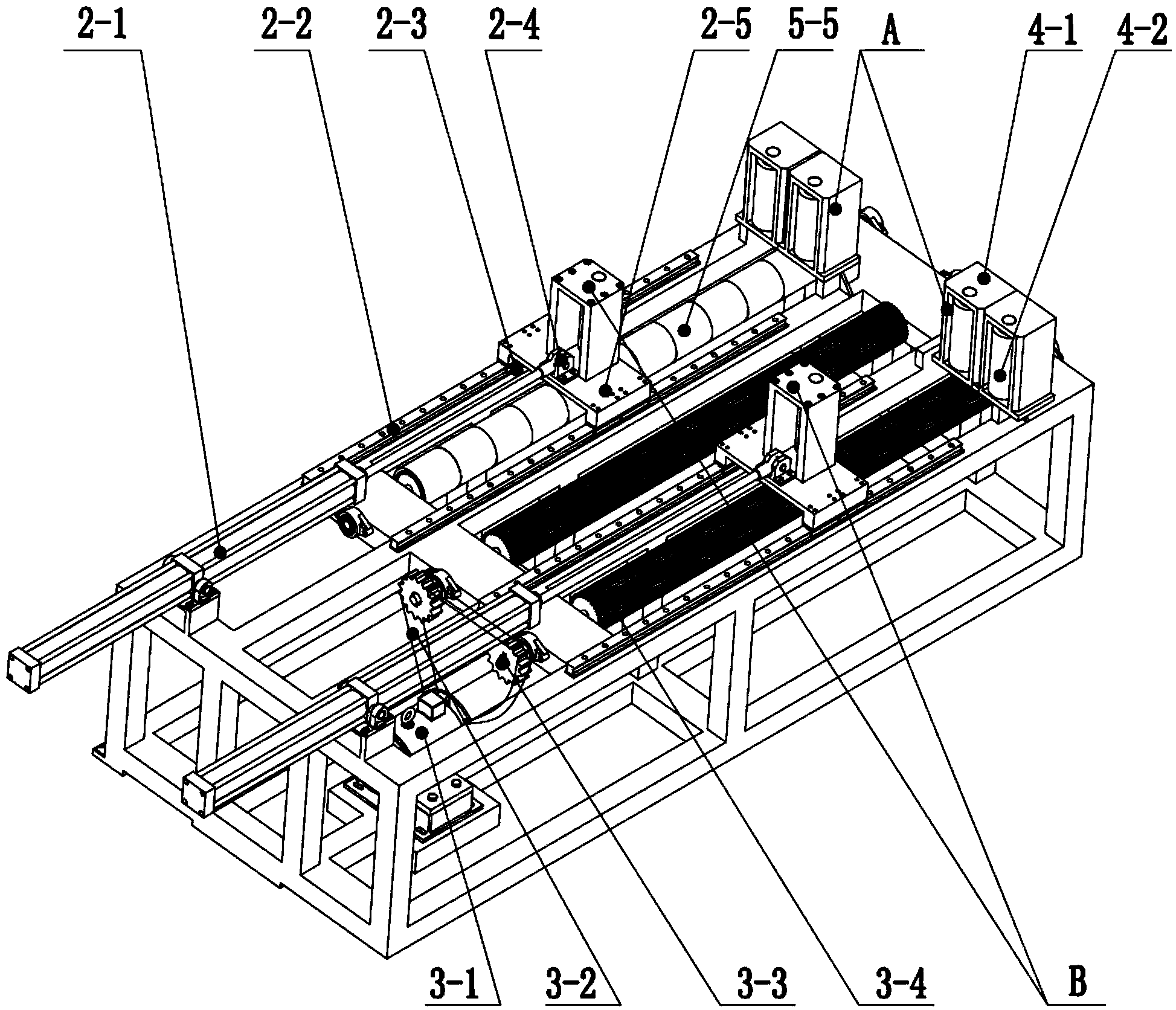

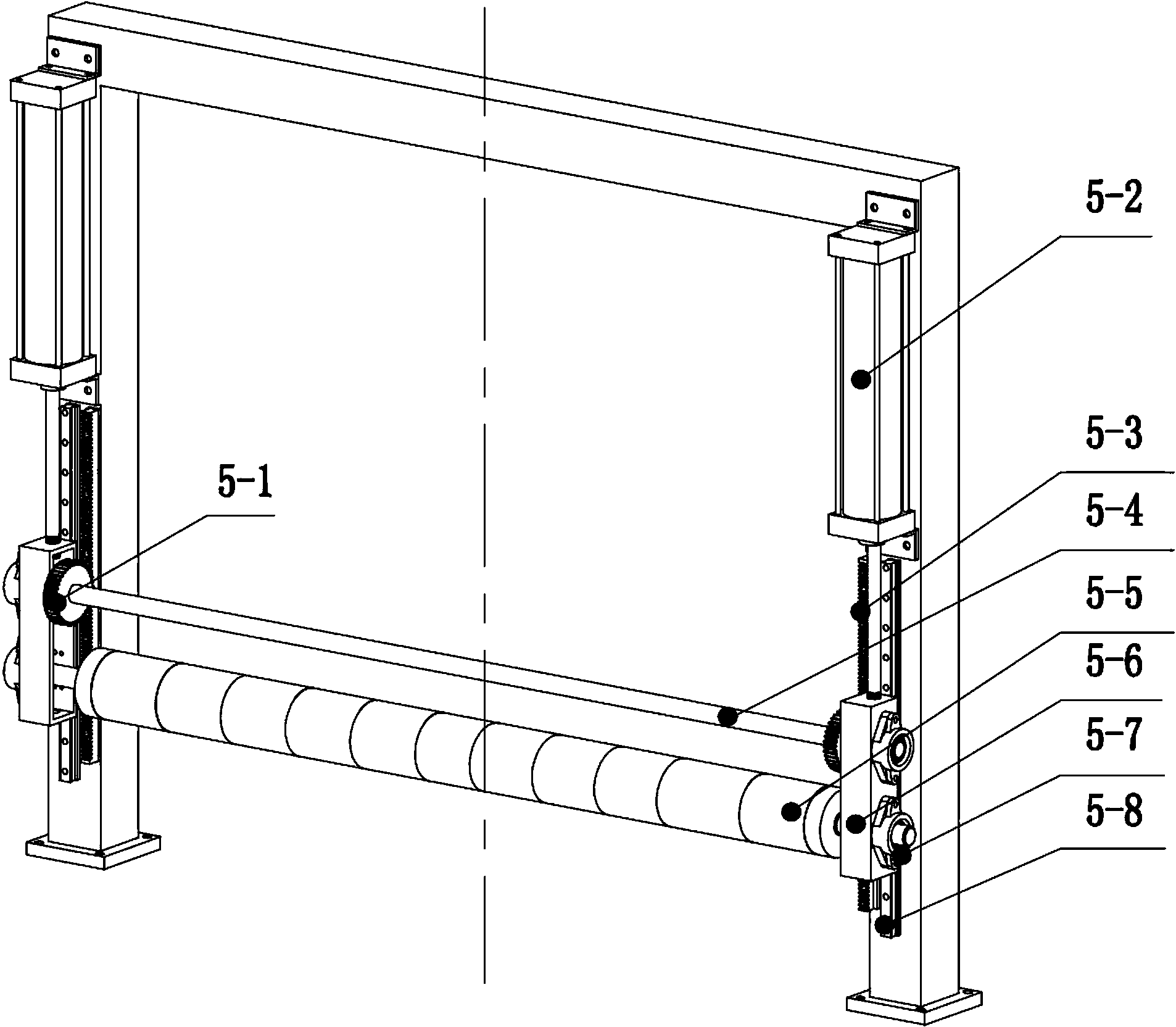

[0016] The present invention is a stable clamping driving device for H-shaped steel, which comprises a frame, a driving roller table, a horizontal clamping device and a vertical pressing device. The driving roller table 3 is arranged on the frame 1, and the horizontal clamping device consists of It is composed of fixed pinch roller set, mobile pinch roller set and horizontal push mechanism arranged on both sides of the frame. Two sets of pinch roller sets are installed on one side of frame 1 at intervals, which is the fixed pinch roller set A; the other There are two sets of mobile pinch roller groups B respectively connected to the push cylinder 2-1 of the horizontal push mechanism 2 through the connection bottom plate 2-5 of the horizontal push mechanism 2, and are arranged on the other side of the frame, which are mobile pinch roller groups, opposite to the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com