Maintaining equipment for ink-jet printer

A technology for inkjet printers and maintenance equipment, applied in printing and other directions, which can solve problems such as dislocation of the top cover and nozzles, smaller internal space, and increased size of inkjet printers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the present invention will be described below with reference to examples in the accompanying drawings, in which the same reference numerals denote the same components throughout. The embodiments are described in order to explain the present invention with reference to the figures.

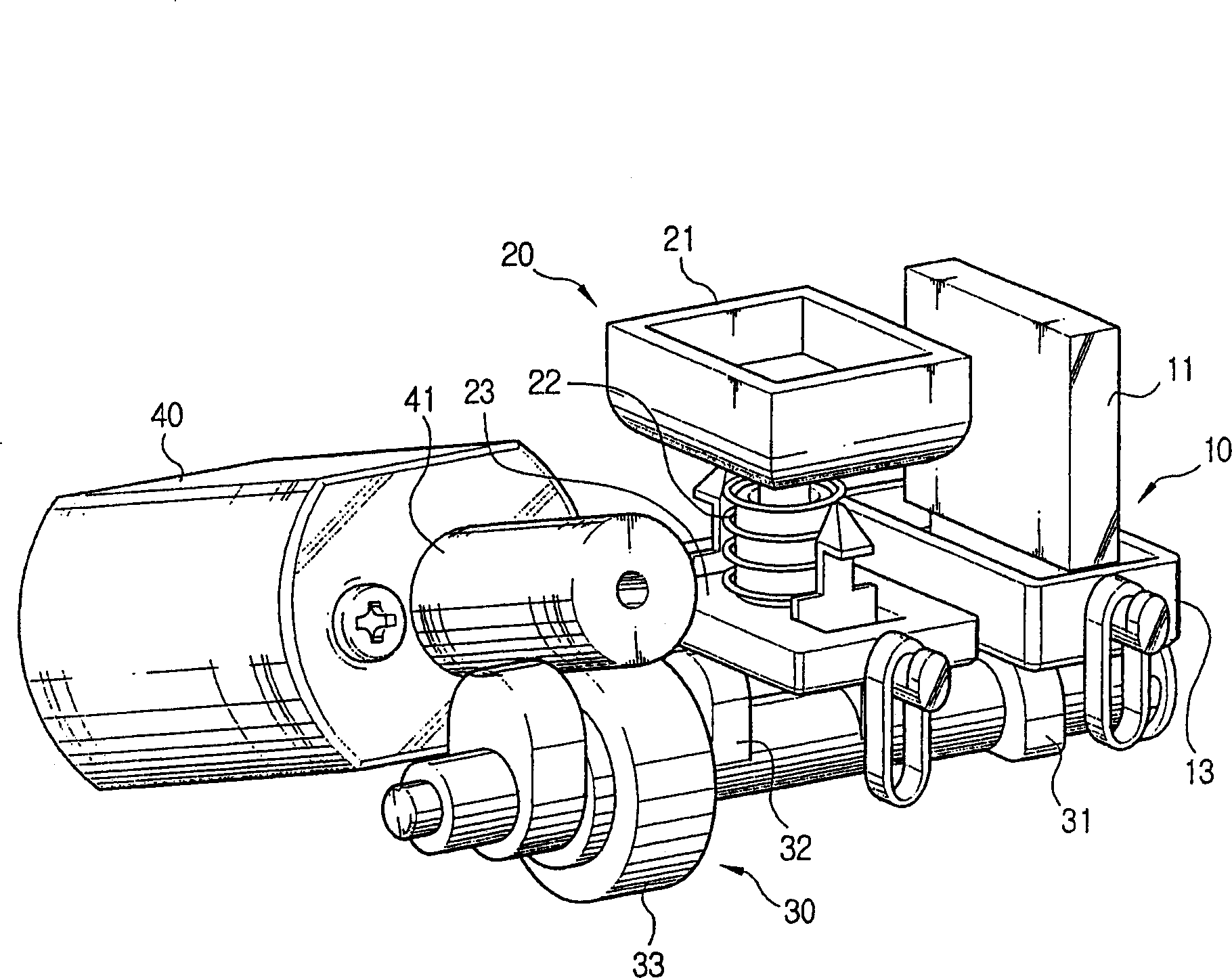

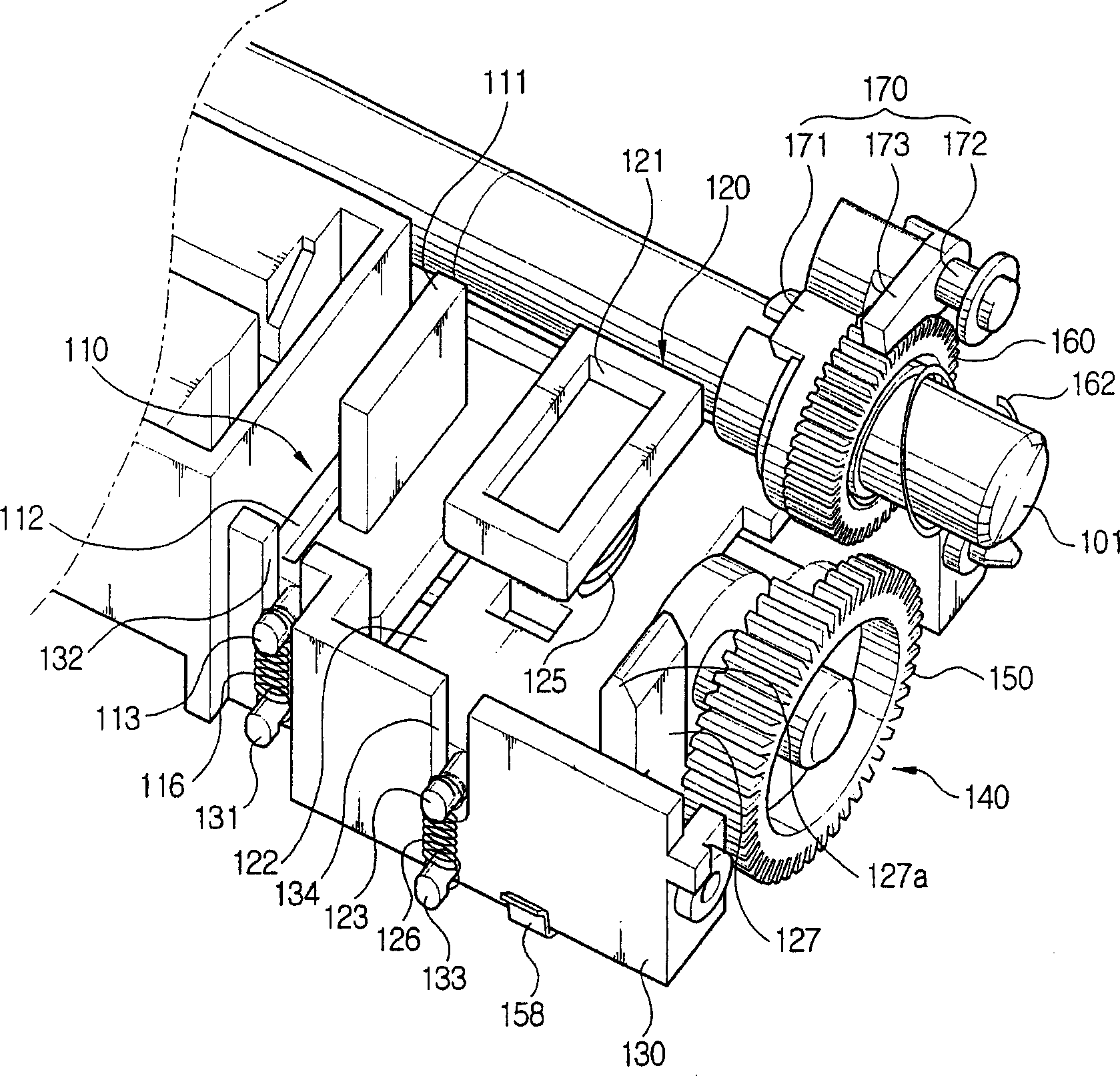

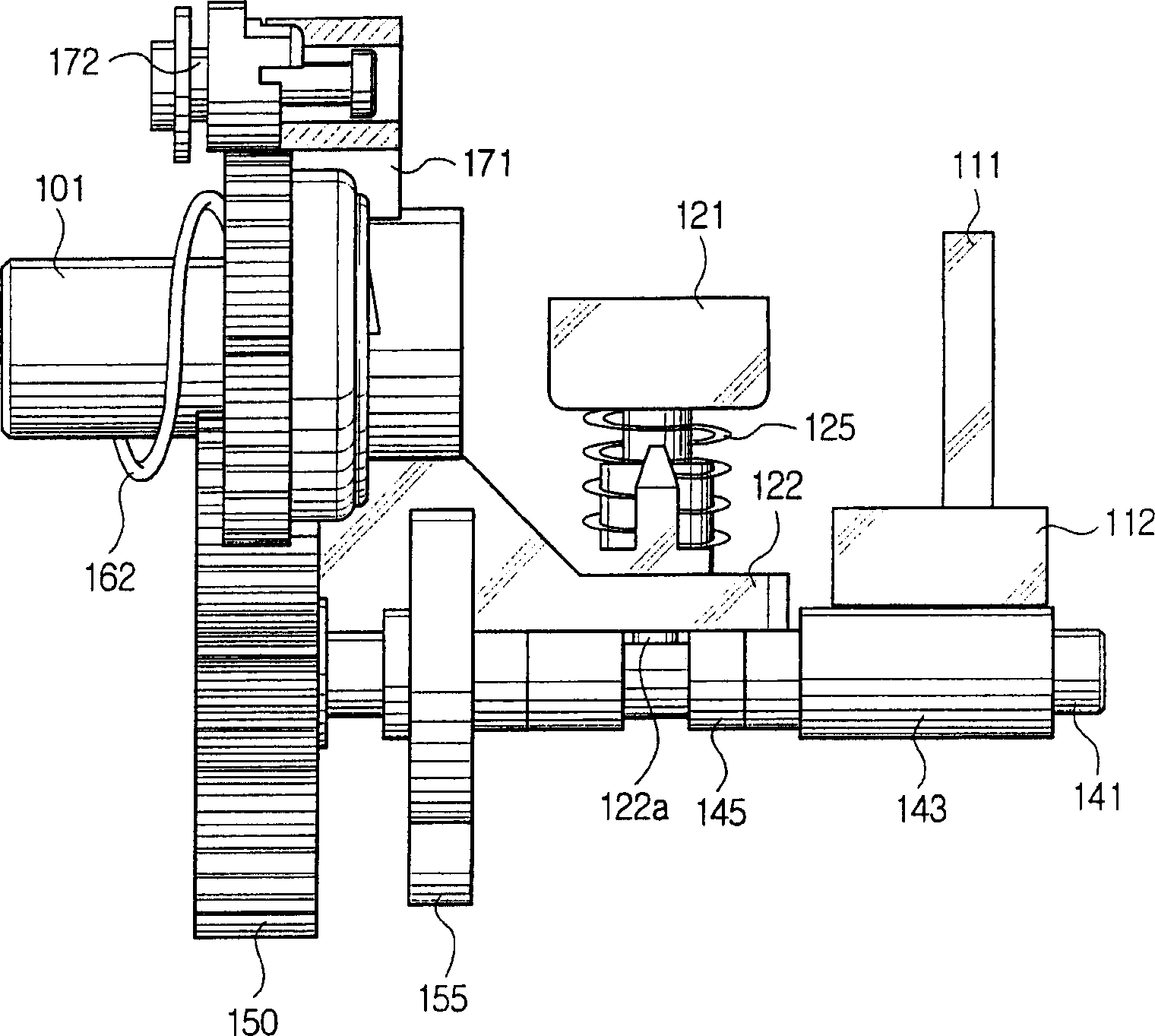

[0050] see Figure 2-6 , the maintenance device for an inkjet printer of the present invention includes: maintenance pieces 110 , 120 , 130 ; maintenance cams 140 ; and connection units 150 , 160 .

[0051] Maintenance members 110 , 120 , 130 maintain one or more nozzles of printheads mounted on carriage 105 . In this embodiment, the maintenance member includes a wiper unit 110 , a top cover unit 120 , and a frame 130 .

[0052] During printing, when the carriage 105 reciprocates relative to the wiper 111 of a predetermined width, the wiping unit 110 wipes ink on the nozzles of the print head. The wiper unit 110 includes a wiper 111 , a wiper guide portion 112 , and a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com