Device for soaking oil on steel rope surface

A steel wire rope and oil-immersed technology, which is applied to rope-making auxiliary devices, textiles and papermaking, textile cables, etc., can solve the problems of scattered on the ground, high labor intensity, environmental pollution, etc., to prolong the cooling time, solve pollution, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

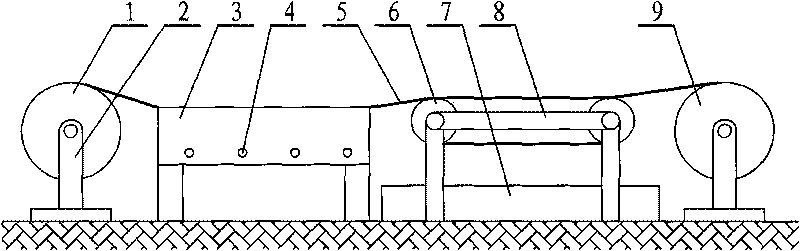

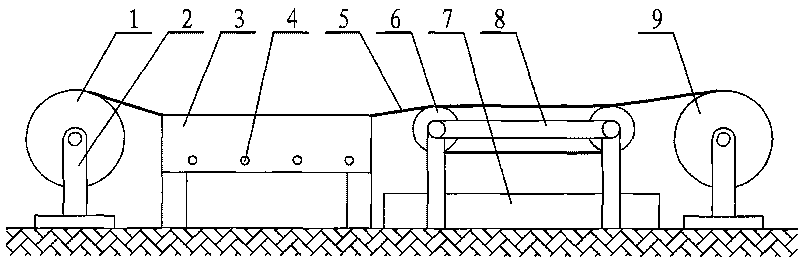

[0011] Such as figure 1 , 2 As shown, the steel wire rope that needs oil immersion treatment is wound on the reel 1 and the wire rope pay-off frame 2, and the steel wire rope 5 passes through the grease heating tank 3 and the pulley block 6, and is wound on the wire reel 9, and placed under the pulley block Oil receiving pan 7 is arranged.

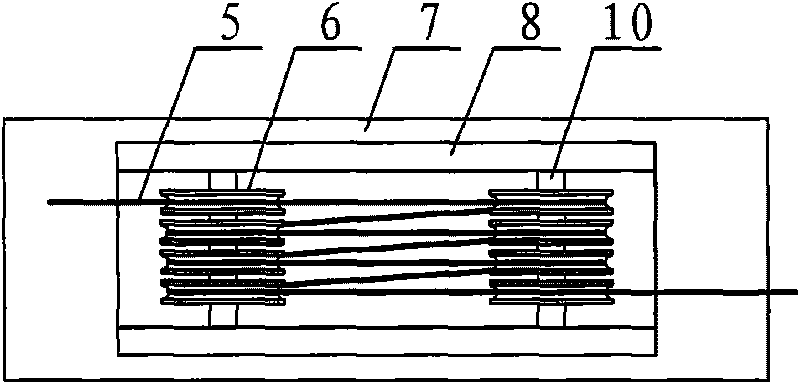

[0012] When in use, first start the electric heating device 4 installed in the grease heating tank through the control system, so that the temperature of the surface grease placed in the grease heating tank is constant at about 100 degrees, and it is in a melting state, and then the steel wire rope that needs to be immersed in oil Through the grease heating groove, the pulley block is wound on the winding wheel 9, and the pulley block is rotatably fixed on the support 8. The pulley block is installed on two shafts 10 parallel to the left and right, and the shaft is fixed on the bracket 8. Four pulleys are installed on each shaft. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com