Electric rail sawing machine

A technology for electric saws and racks, which is applied in sawing machine devices, metal sawing equipment, metal processing equipment, etc., can solve the problems affecting the service life of cutting tools and high cutting costs, so as to improve cutting quality, reduce cutting density, and improve use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

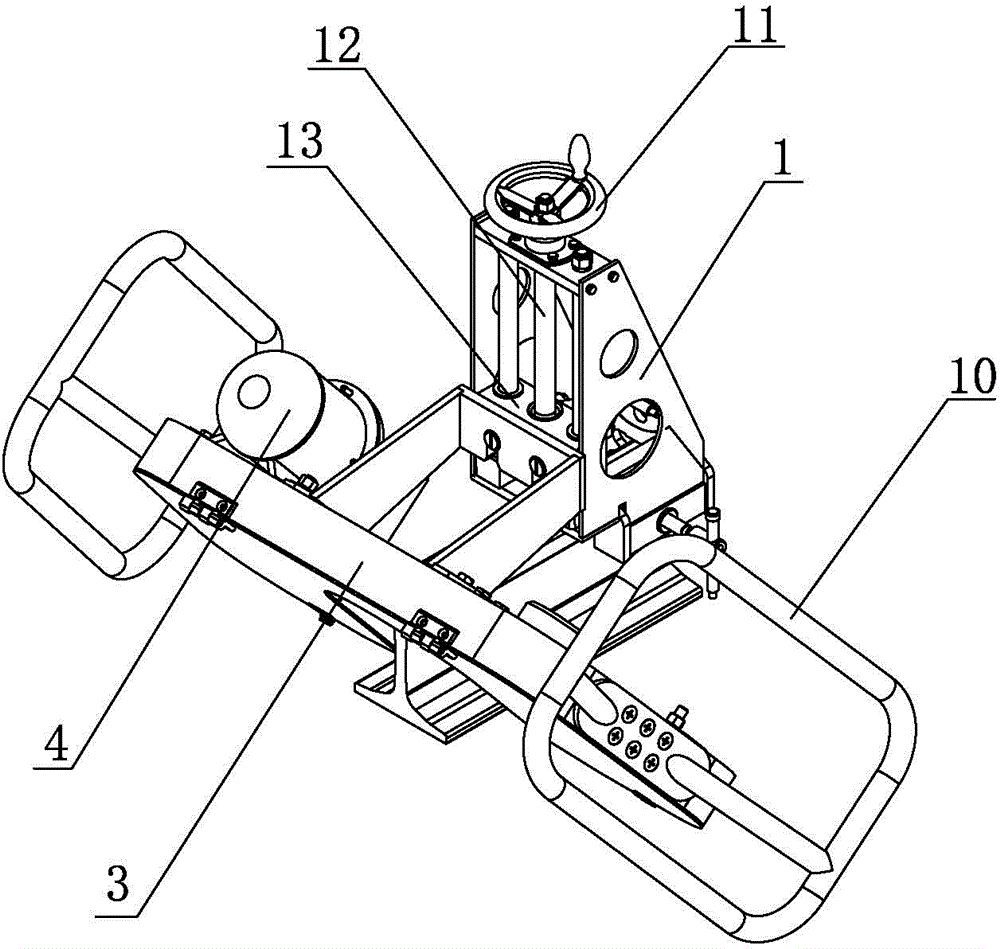

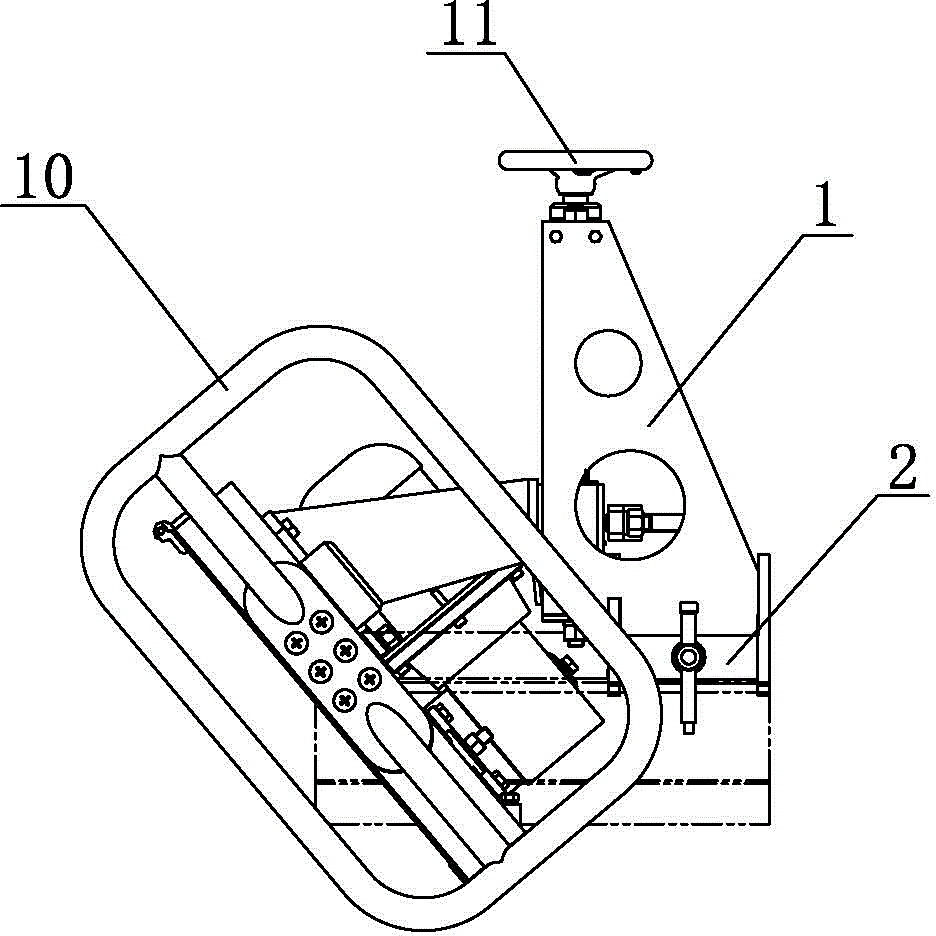

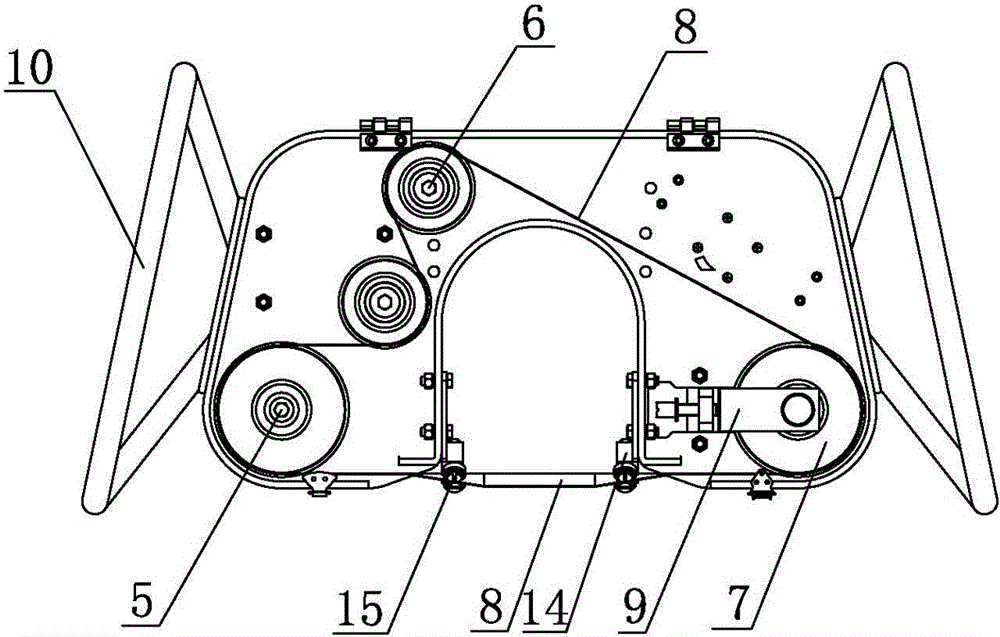

[0021] Embodiment 1: An electric rail sawing machine, including a rail clamping mechanism and a cutting mechanism, the cutting mechanism is installed on the rail clamping mechanism, the rail clamping mechanism includes a frame 1, a rail clamp 2 and a lifter, and the rail clamp 2 is fixed on the frame 1 bottom, the lifter is connected to the top of the frame 1, and the cutting mechanism is connected and installed with the lifter; the cutting mechanism includes the box body 3, the motor 4, the driving wheel 5, the tensioning wheel 6, the driven wheel 7 groups and the cutting saw blade 8, the driving wheel 5 and the tensioning pulley 6 are respectively arranged on the left and right sides of the inside of the box body 3, the motor 4 is installed on the back of the box body 3 and connected with the driving wheel 5, and 7 groups of driven wheels are arranged between the driving wheel 5 and the tensioning pulley 6 Inside the box body 3, the cutting saw blade 8 passes through the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com