Factory equipment processing system, equipment database server and method

A technology for factory equipment and processing systems, applied in transmission systems, instruments, electrical components, etc., can solve the problems of high labor costs and low maintenance efficiency, and achieve the effect of reducing labor costs, improving production efficiency, and improving maintenance efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

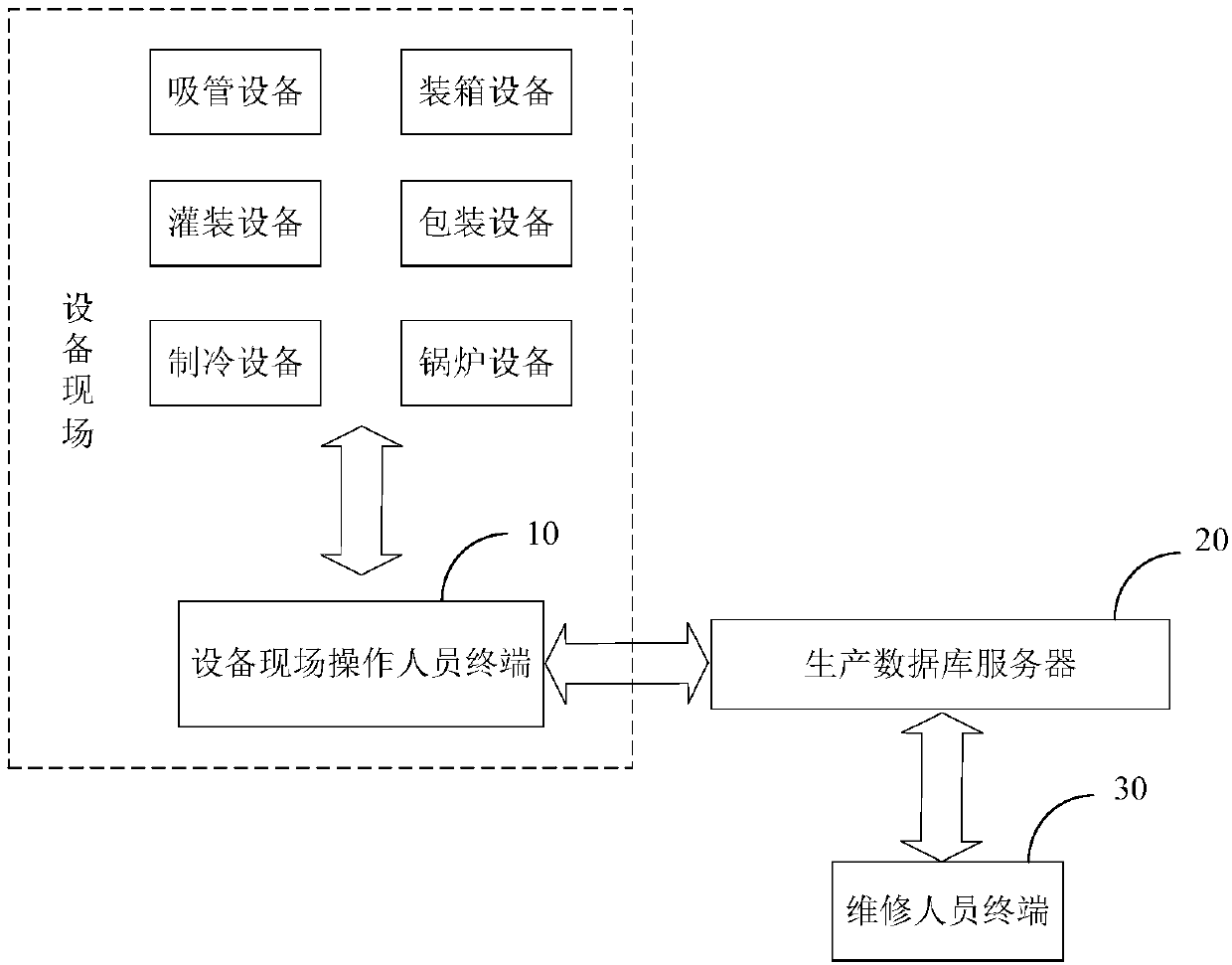

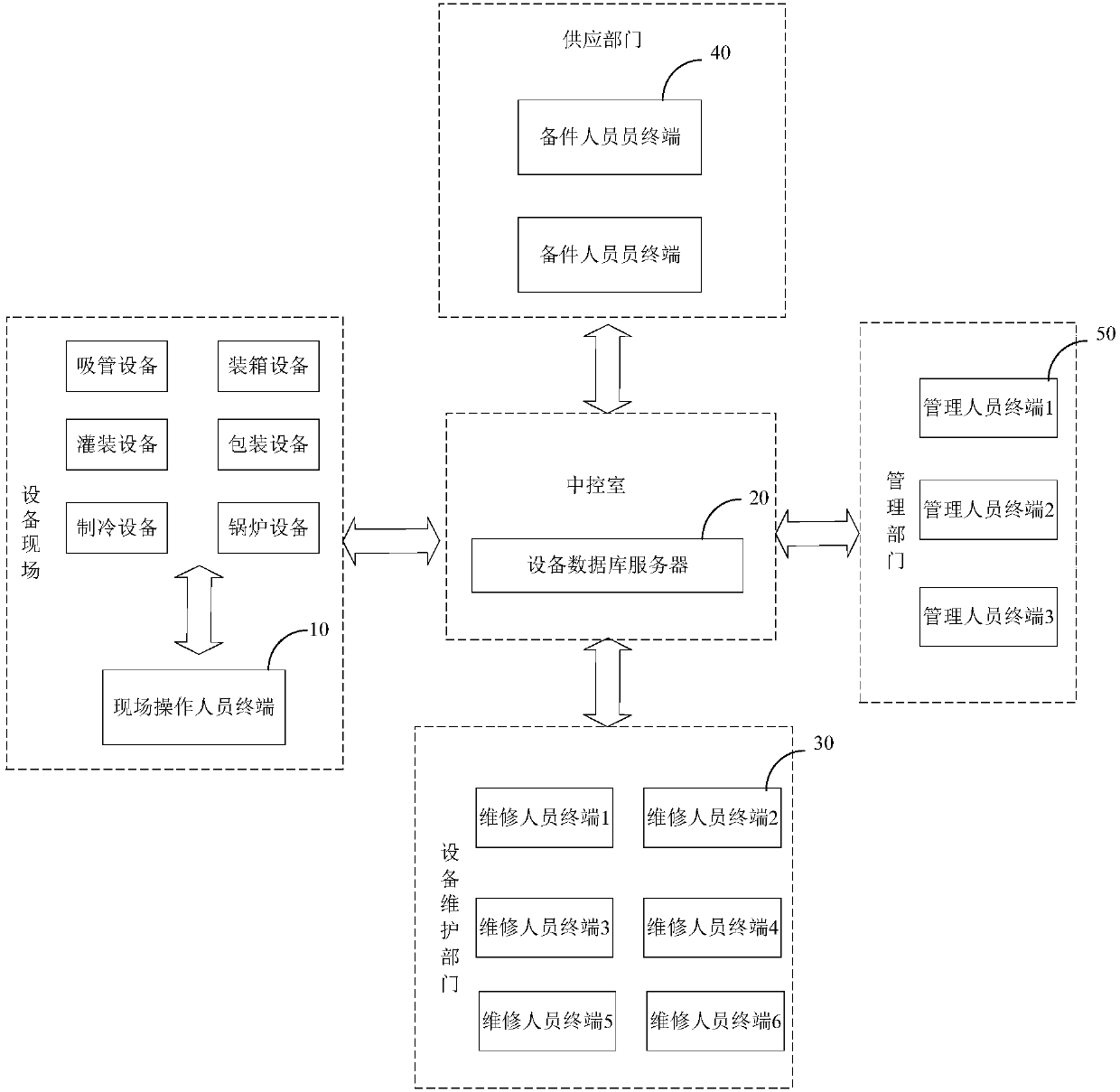

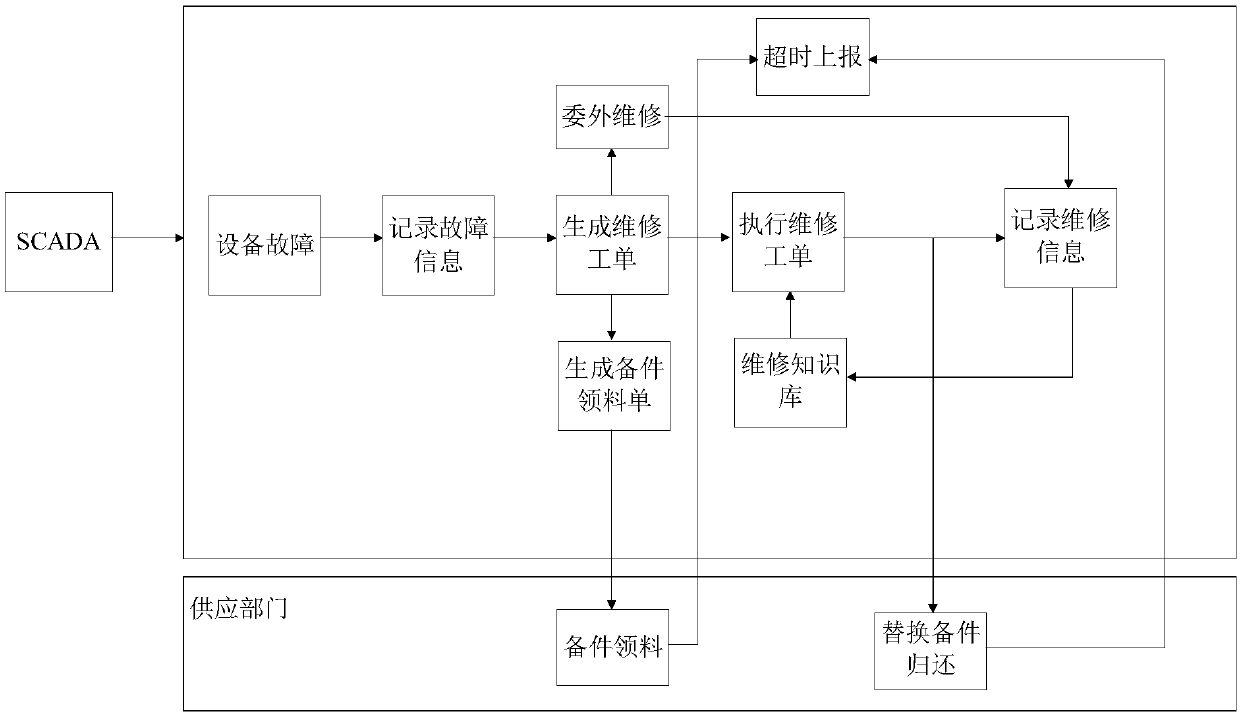

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0027] Since the inventor discovered the technical problems existing in the prior art, he proposed a plant equipment processing system and method, as well as an equipment database server, which realized the automatic generation of maintenance work orders for equipment to be repaired and solutions for faults of equipment to be repaired. And the maintenance work order and solution are automatically pushed to the maintenance personnel's terminal. The maintenance personnel do not need to go to the equipment site to check the fault. According to the fault solution of the equipment to be repaired, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com