Steel plate spring assembly fatigue tester

A fatigue testing machine and leaf spring technology, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, can solve the problems of occupying a large space, high cost, heavy loading mechanism, etc., and achieves convenient operation, low cost, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in detail with reference to the accompanying drawings.

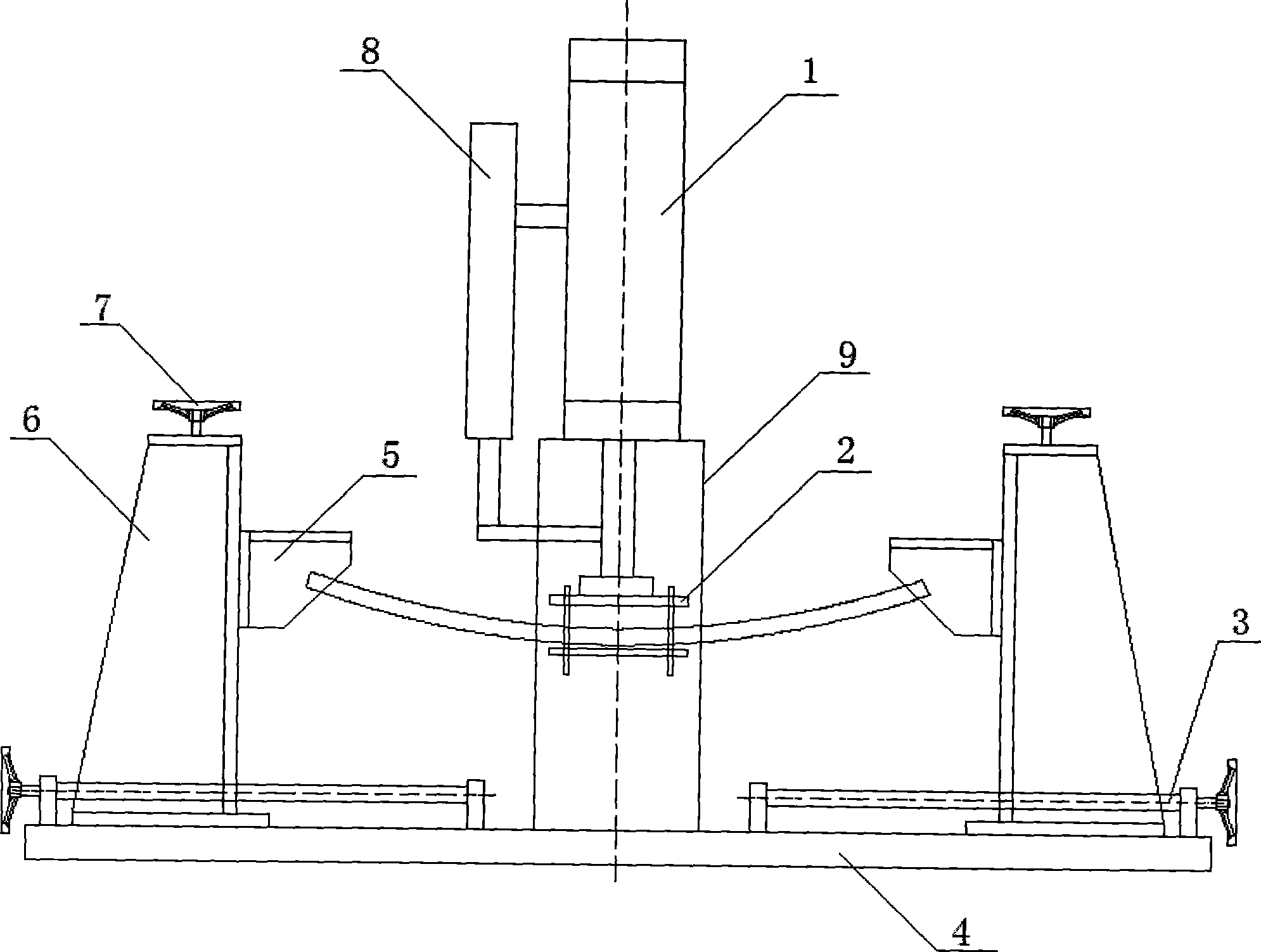

[0012] figure 1 It is a schematic structural diagram of the leaf spring assembly fatigue testing machine of the present invention. As shown in the figure, the leaf spring assembly fatigue testing machine of the present invention includes a servo hydraulic cylinder 1, a strut 6, a displacement sensor 8, a base 4 and a strut clamp 5, etc. A bracket 9 is installed in the middle part of the base 4, and the bracket 9. A servo hydraulic cylinder 1 is fixed on the upper part, and the servo hydraulic cylinder 1 is communicated with an external servo hydraulic system (not shown) through a hydraulic pipe. The piston rod of the servo hydraulic cylinder 1 faces downward, and a fixture 2 is installed on the head of the piston rod; a displacement sensor 8 is fixedly installed on the outside of the servo hydraulic cylinder 1, and the sensing head of the displacement sensor 8 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com