Digital detection system based on diamond roller dressing grinding machine

A technology of diamond roller and detection system, applied in the field of digital detection system, can solve the problems of inability to realize trimming automation, improve work efficiency, ensure product qualification rate, disadvantage, etc., achieve repeated coverage, reduce processing cost and reject rate, and improve The effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below in conjunction with the accompanying drawings.

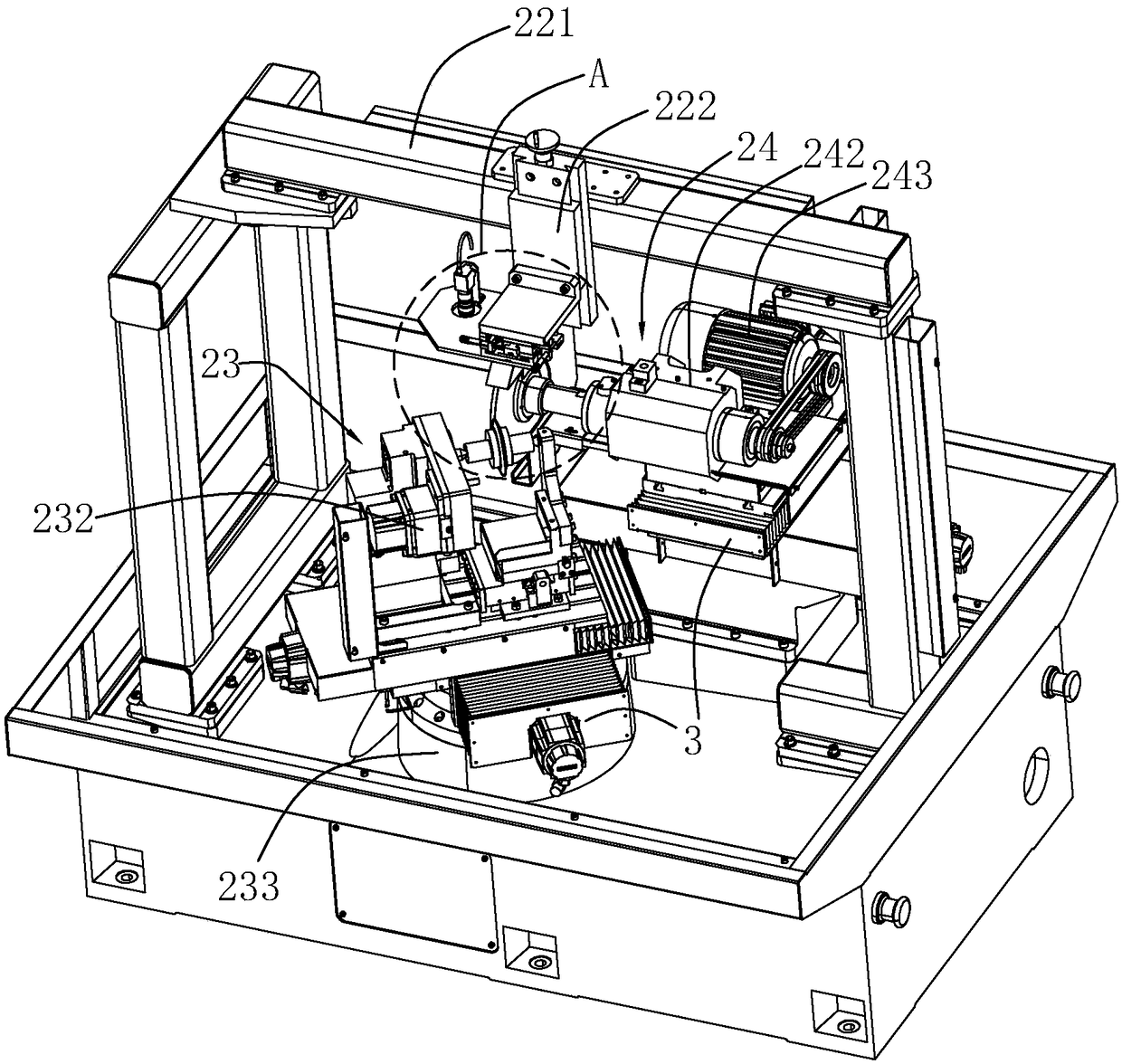

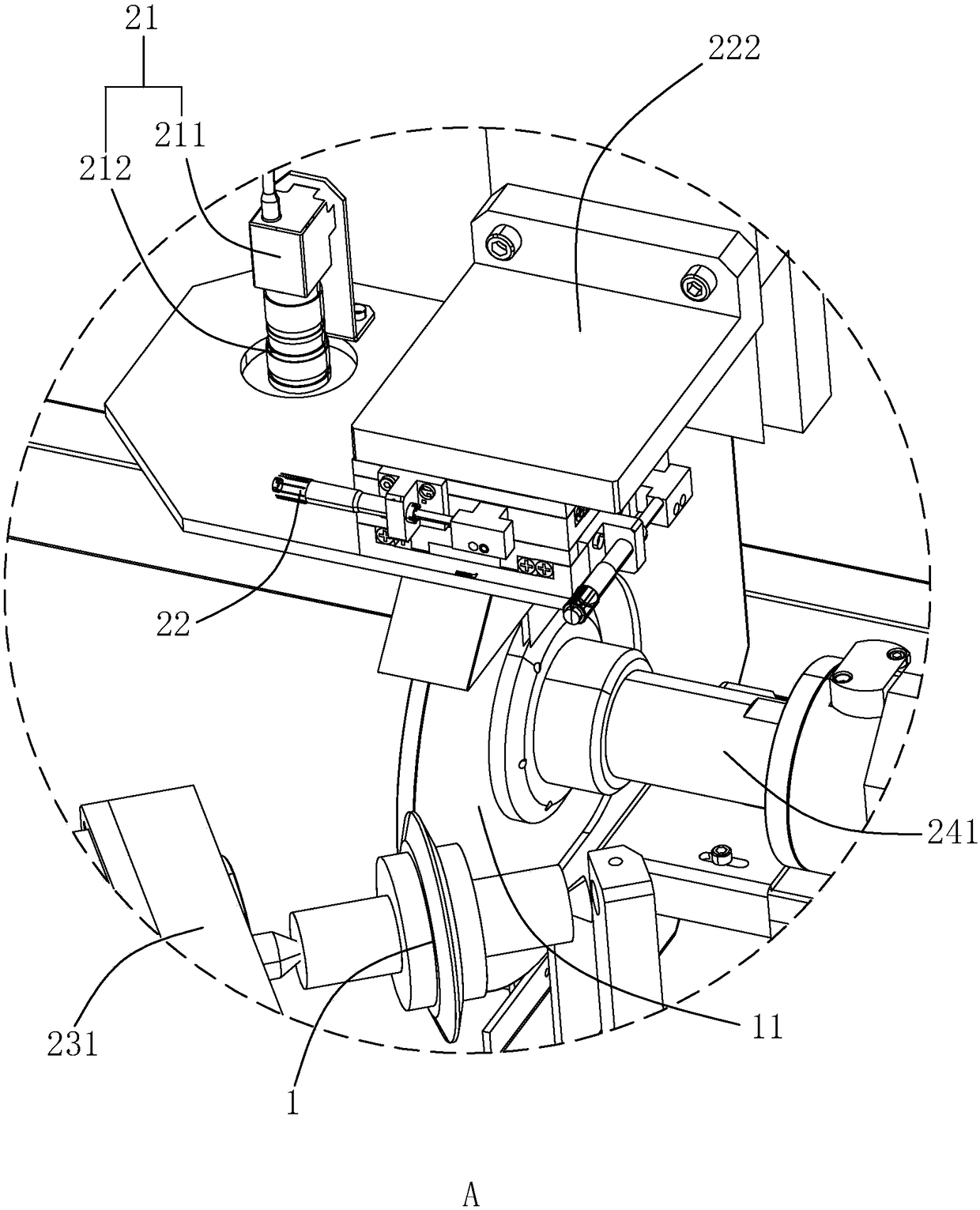

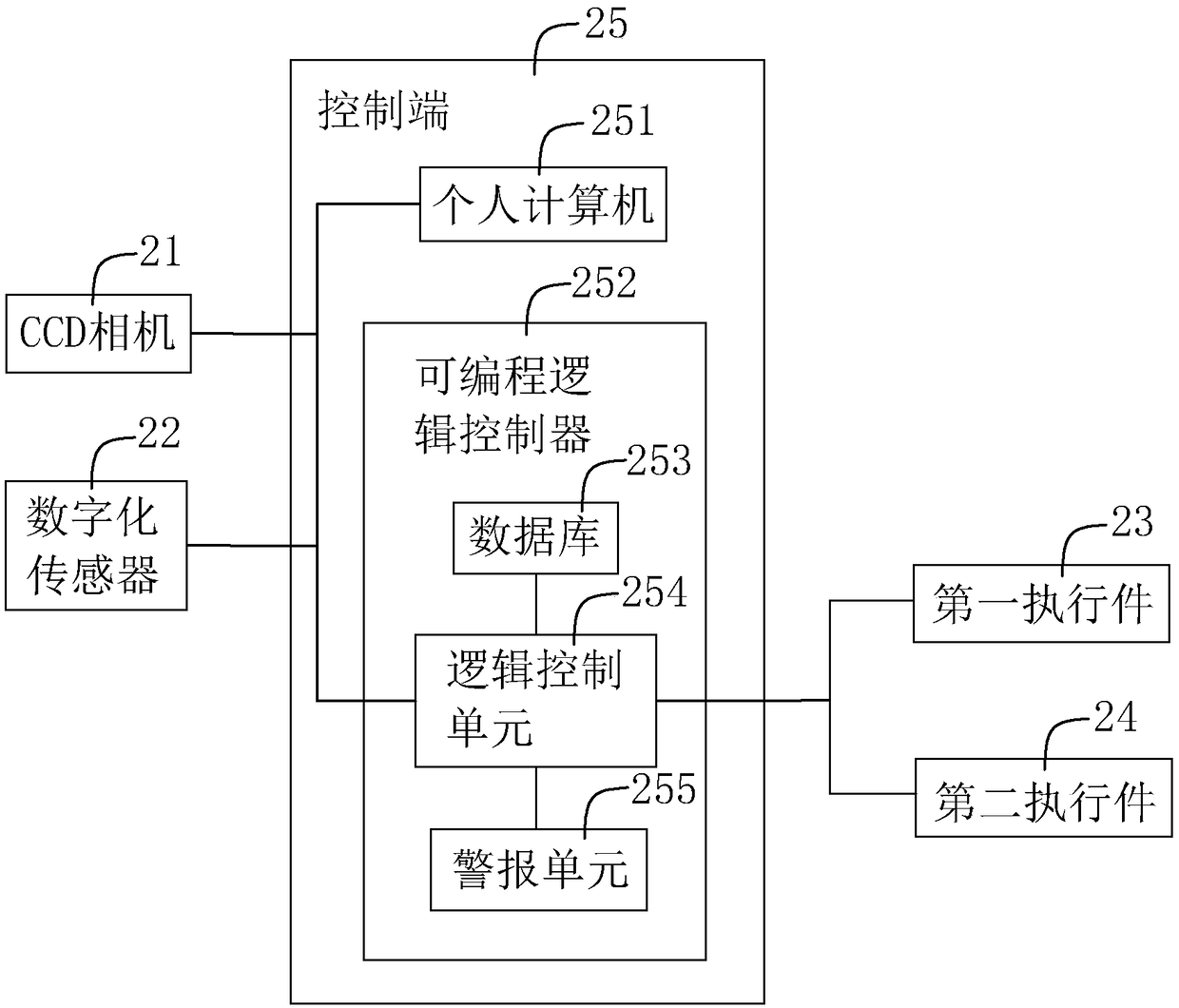

[0055] The invention discloses a digital detection system based on a diamond roller dressing grinder, such as figure 1 and figure 2 As shown, a diamond roller 1 and a grinding wheel 11 are respectively installed on the workbench of the dressing grinder. According to the technical requirements of the processed parts, the diamond roller 1 that conforms to the contour shape, size and precision is manufactured accordingly. By installing the diamond roller 1 on the dressing grinder The trimming device comes up to trim common vitrified grinding wheel or CBN grinding wheel, grinding parts after grinding wheel 11 moldings. That is, before grinding, a coordinate subsystem 3 based on X-axis and Y-axis adjustment is set on the worktable of the dressing grinder, and the grinding wheel 11 has a certain geometric shape (practice) through the coordinate subsystem 3 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com