All-in-one machine of semiconductor device for testing, sorting, marking and braiding and one-stop processing method

A processing method and semiconductor technology, applied in the direction of semiconductor/solid-state device testing/measurement, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as waste of labor, complicated operation, and failure to meet market demand, so as to improve work efficiency, The effect of guaranteeing the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

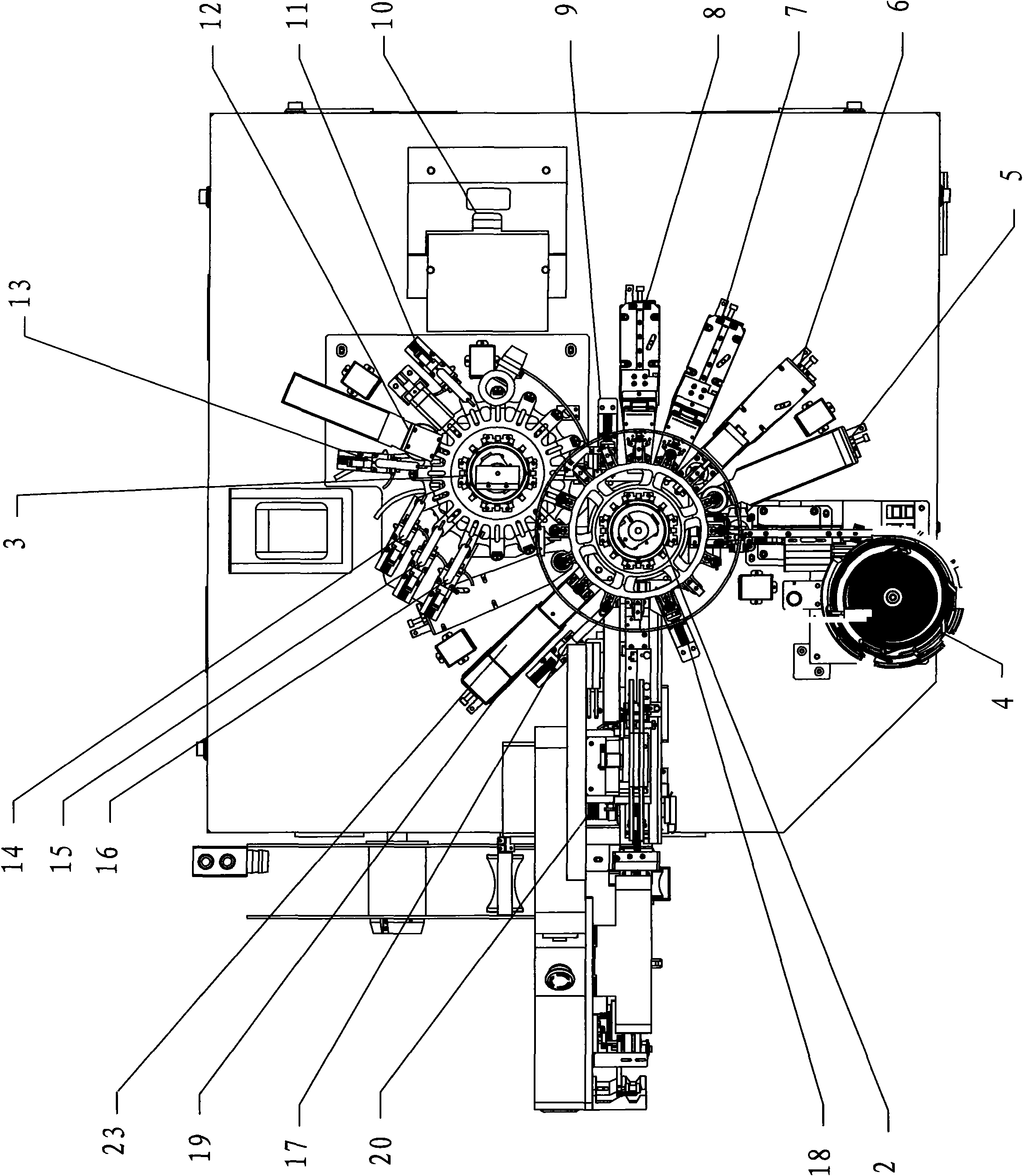

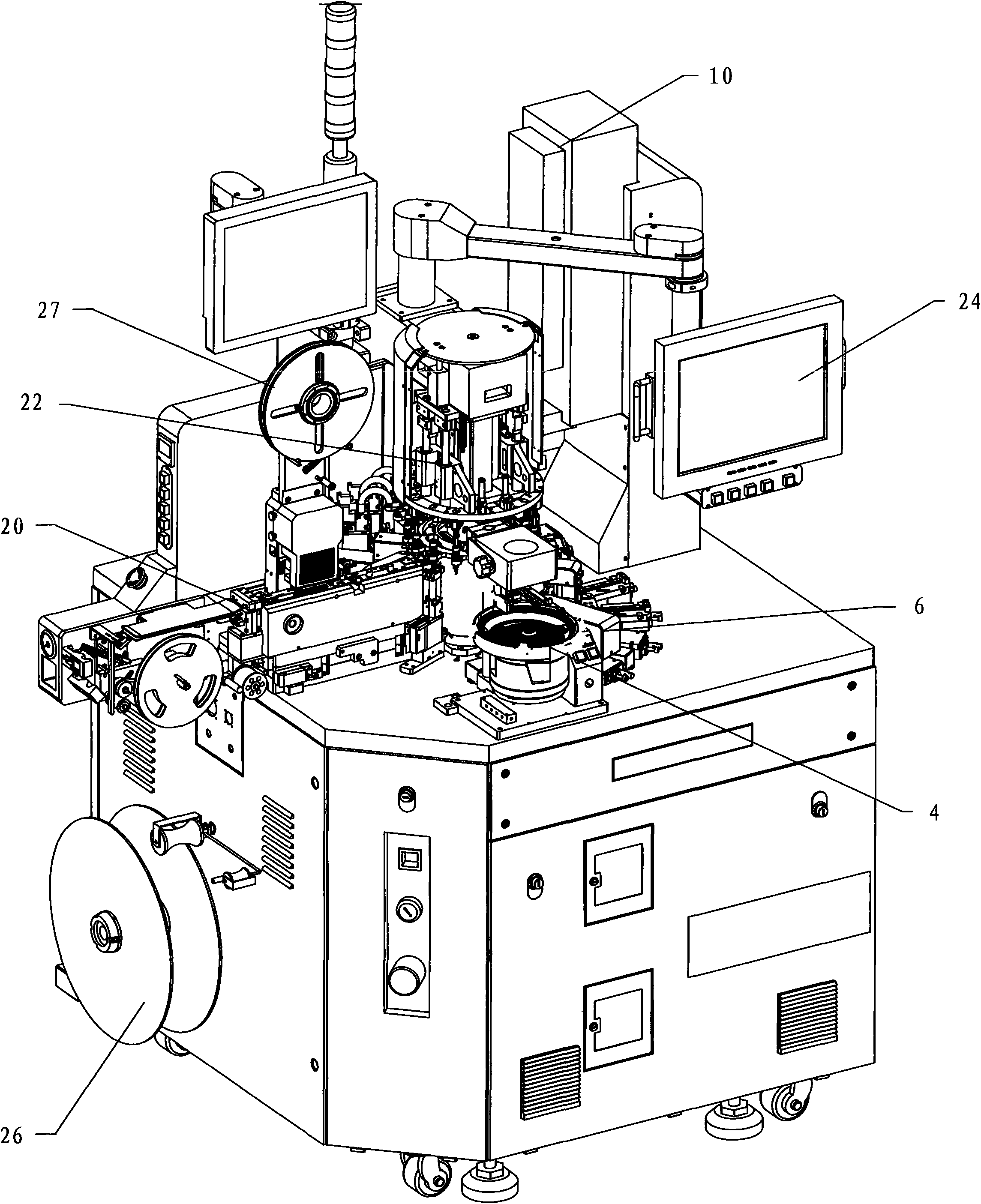

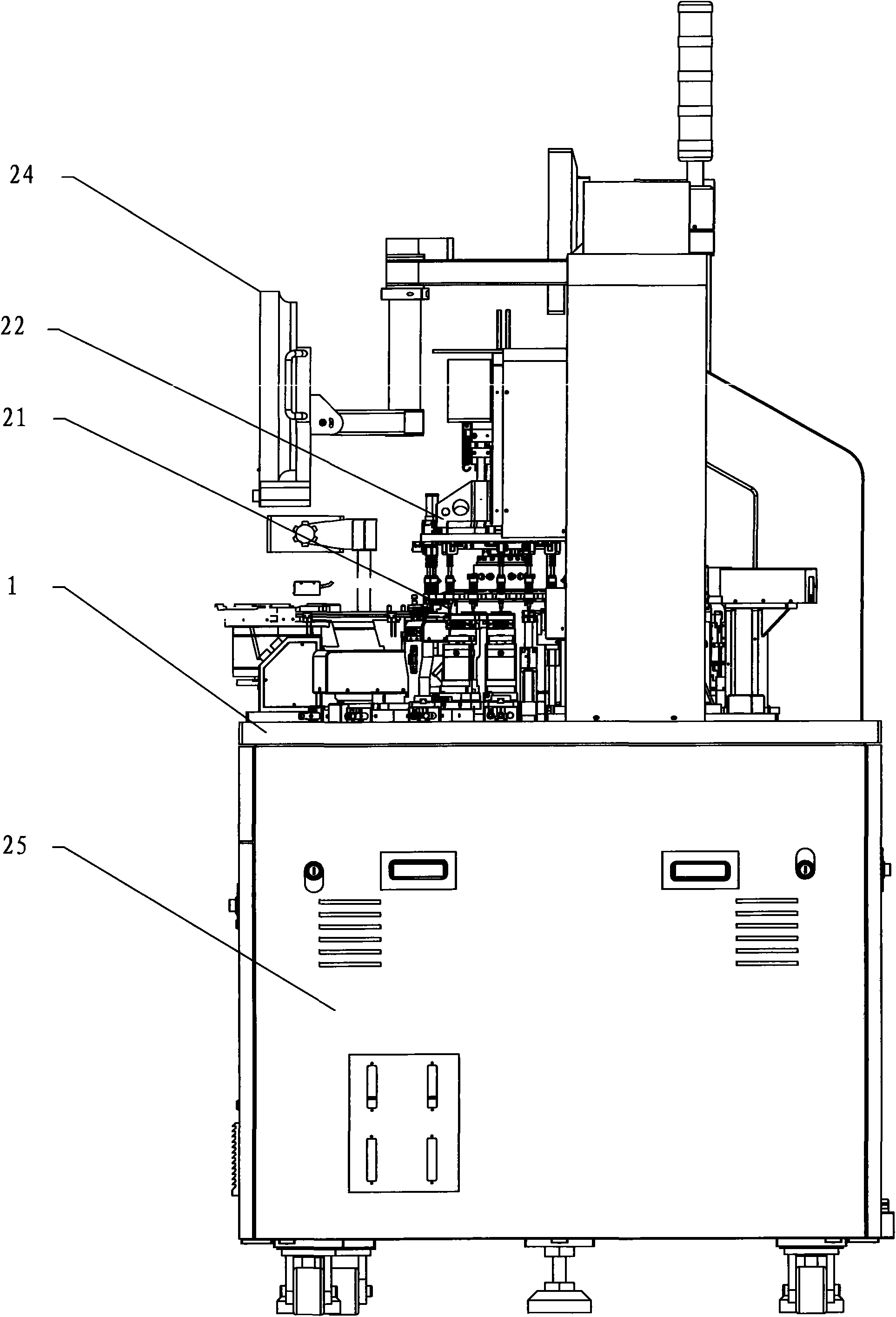

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 as shown, figure 1 It is the main turret system and the laser marking turret system working position and working position distribution diagram of the present invention, figure 2 It is a schematic diagram of the three-dimensional structure of the present invention, image 3 It is a side view structural schematic diagram of the present invention, Figure 4 It is a schematic diagram of station distribution of the device processing system of the present invention. Combine now figure 1 , figure 2 , image 3 , Figure 4 Describe the embodiment of the present invention in detail: a semiconductor device testing, sorting, marking and taping integrated machine, including a machine body 1 and various device processing systems that are fixedly connected with the machine body, and a 16 working system is provided on the machine body 1 The main turret system 2 of the station and the laser marking turret system 3 of a 16 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com