New method and equipment for preparing vacuum glass faceplate

A technology of vacuum glass and a new method, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., to achieve the effect of beautiful exhaust port, shortened time and high vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Cut, edge and clean the original glass plate according to the required size. The original glass plate can be ordinary float glass, tempered glass, various coated glass, self-cleaning glass, low-emissivity glass, high visible light transmittance glass and so on.

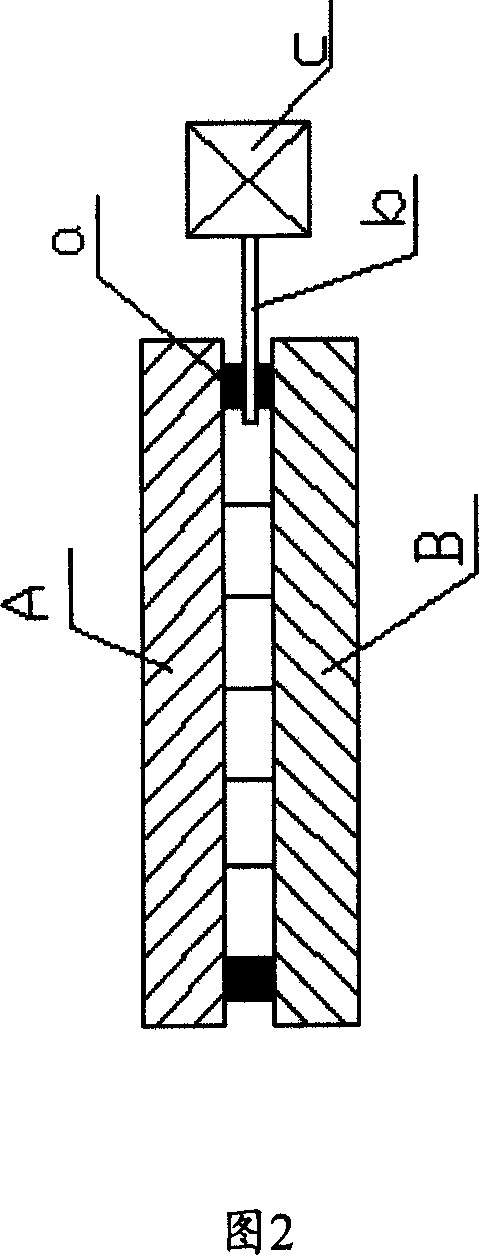

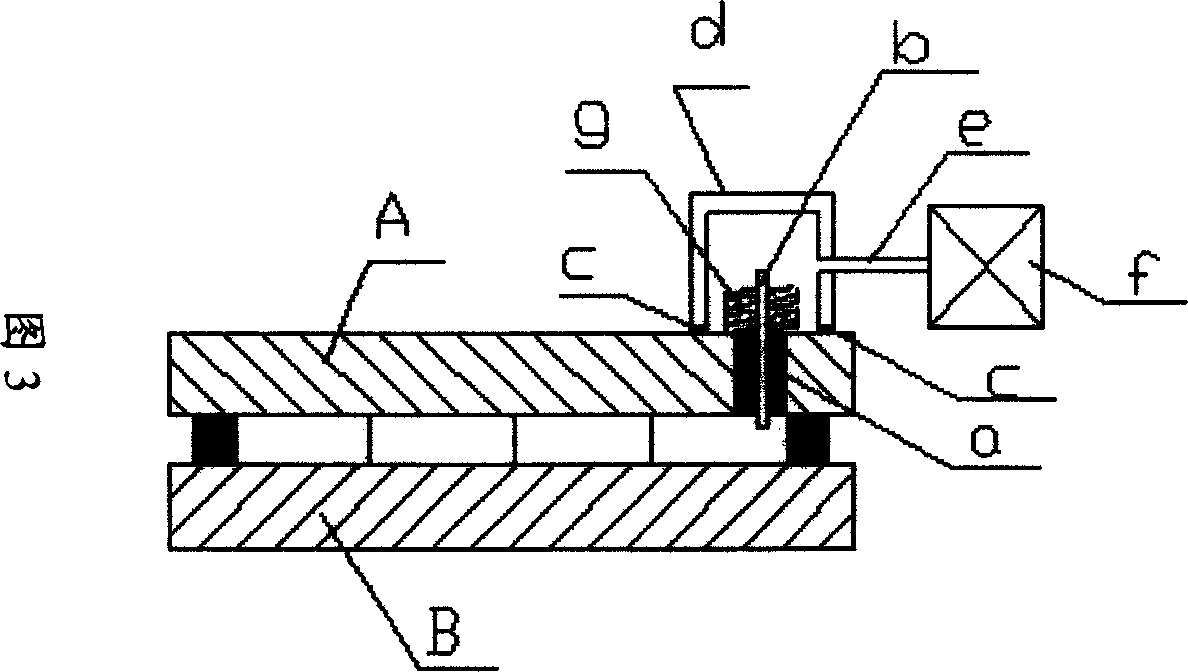

[0054] (2) Use a mechanical drill or a laser drilling machine to make a vent hole with a diameter of 2mm on a glass plate. This piece of glass is called the front substrate glass. Correspondingly, the other piece of glass is called the rear substrate glass.

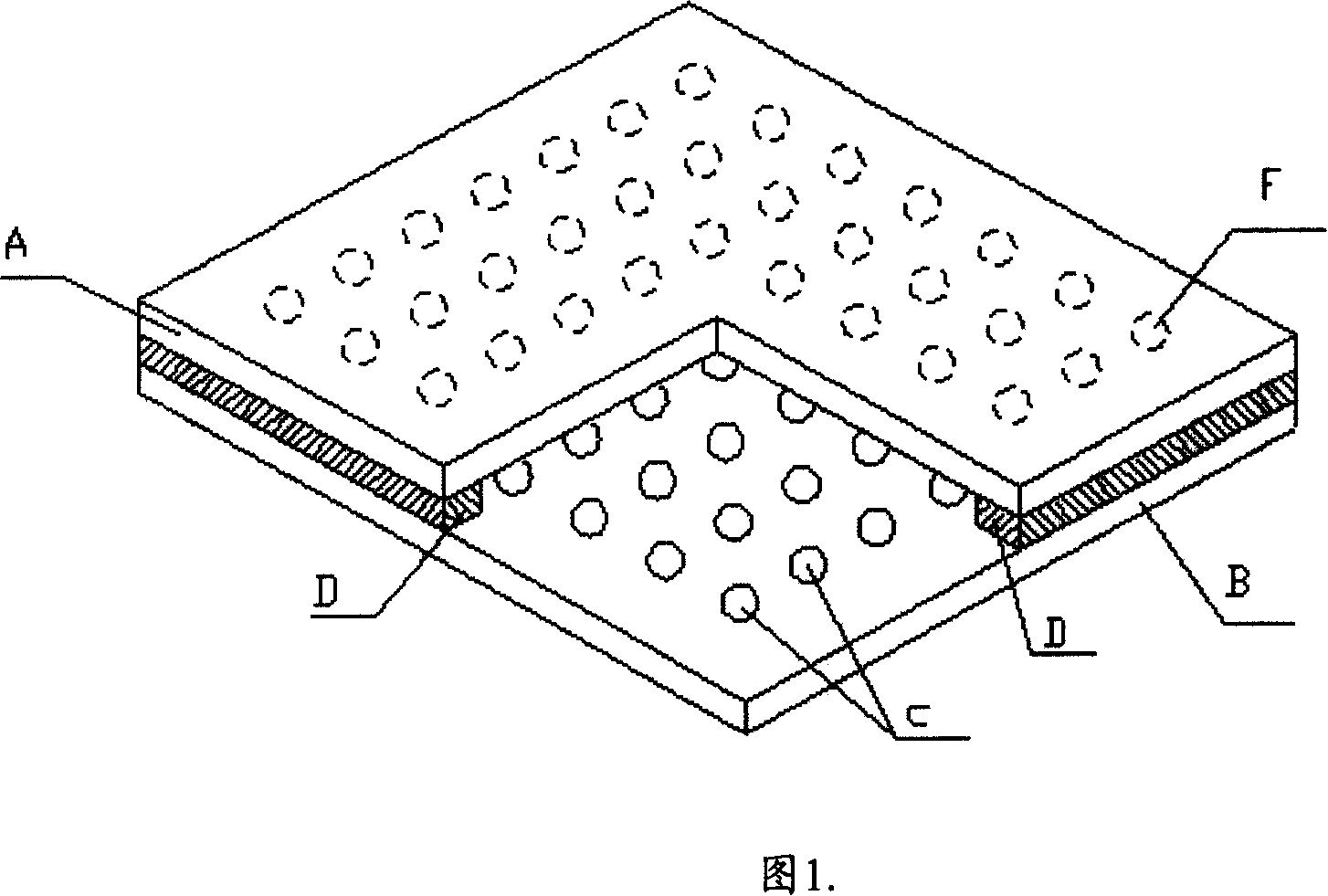

[0055] (3) Make isolation support points on the rear substrate glass by screen printing. Use amorphous low-melting glass powder (hereinafter referred to as low-melting glass powder A) with a coefficient of thermal expansion slightly smaller than that of the glass panel and an organic solution to prepare a rheological slurry suitable for screen printing. Then use the screen printing method to print wet film dots with a diameter of about 0.5mm and a thi...

Embodiment 2

[0063] (1) Cut, edge and clean the original glass plate according to the required size. The original glass plate can be ordinary float glass, tempered glass, various coated glass, self-cleaning glass, low-emissivity glass, high visible light transmittance glass and so on.

[0064] (2) Use a mechanical drill or a laser drilling machine to make a vent hole with a diameter of 1mm on a glass plate. This piece of glass is called the front substrate glass. Correspondingly, the other piece of glass is called the rear substrate glass.

[0065] (3) Make isolation support points on the rear substrate glass by screen printing. A slurry with rheological properties suitable for screen printing is prepared by using amorphous low-melting glass powder (hereinafter referred to as low-melting glass powder A) with a thermal expansion coefficient slightly smaller than that of the glass panel and an organic solution. Then use the screen printing method to print wet film dots with a diameter of ab...

Embodiment 3

[0073] (1) Cut, edge and clean the original glass plate according to the required size. The original glass plate can be ordinary float glass, tempered glass, various coated glass, self-cleaning glass, low-emissivity glass, high visible light transmittance glass and so on.

[0074] (2) Use a mechanical drill or a laser drilling machine to make an exhaust hole with a diameter of 3mm on a glass plate. This piece of glass is called the front substrate glass. Correspondingly, the other piece of glass is called the rear substrate glass.

[0075] (3) Make isolation support points on the rear substrate glass by screen printing. A slurry with rheological properties suitable for screen printing is prepared by using amorphous low-melting glass powder (hereinafter referred to as low-melting glass powder A) with a thermal expansion coefficient slightly smaller than that of the glass panel and an organic solution. Then use the screen printing method to print wet film dots with a diameter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com