Container with Improved Crush Resistance

a technology of container and crush resistance, applied in the field of containers, can solve the problems of increasing the profitability of manufacturers, affecting consumers, and essentially impossible to sell many products such as liquid products without containers, so as to improve the circumferential strength of containers, improve the crush resistance, and increase the load bearing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

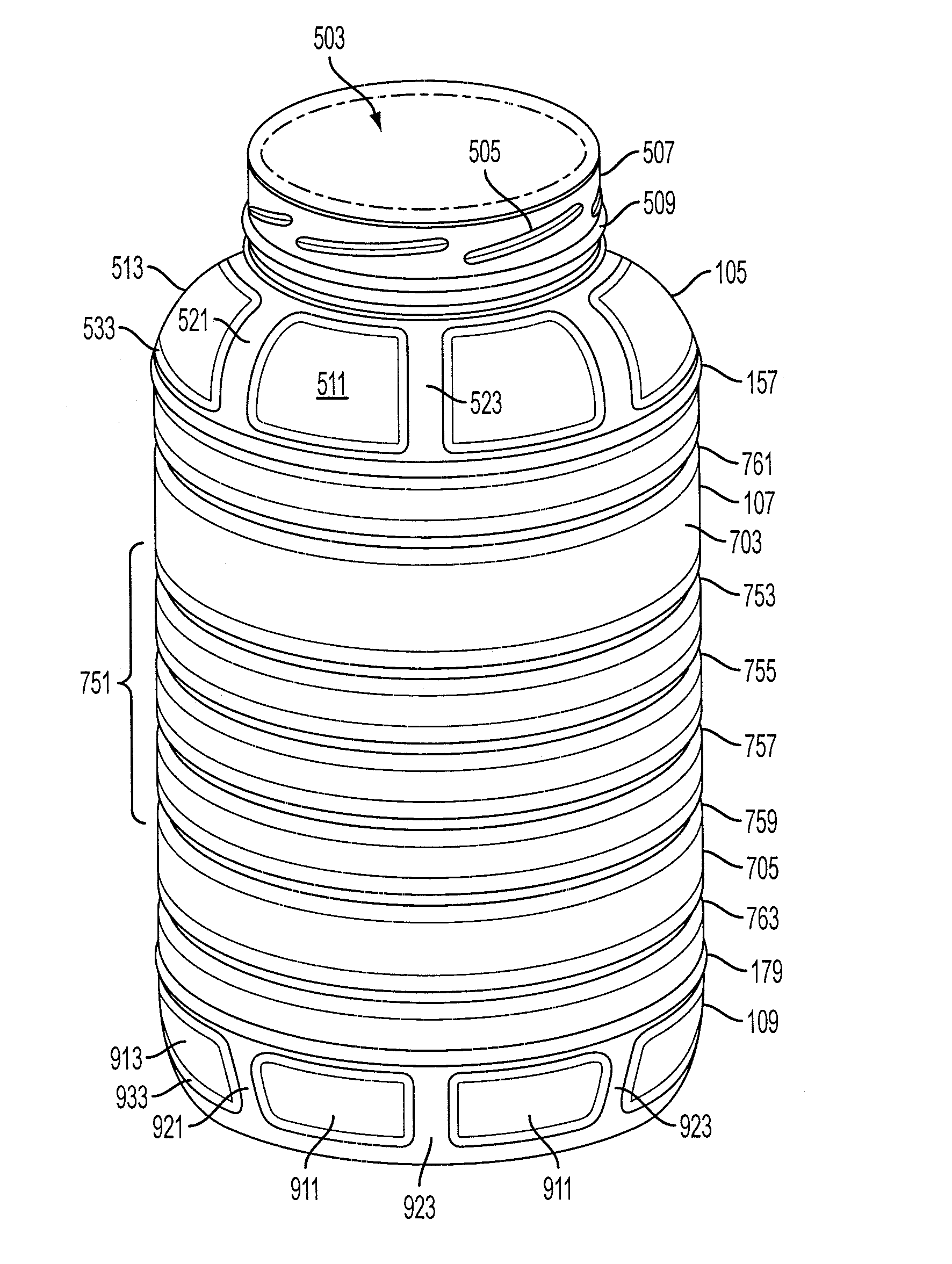

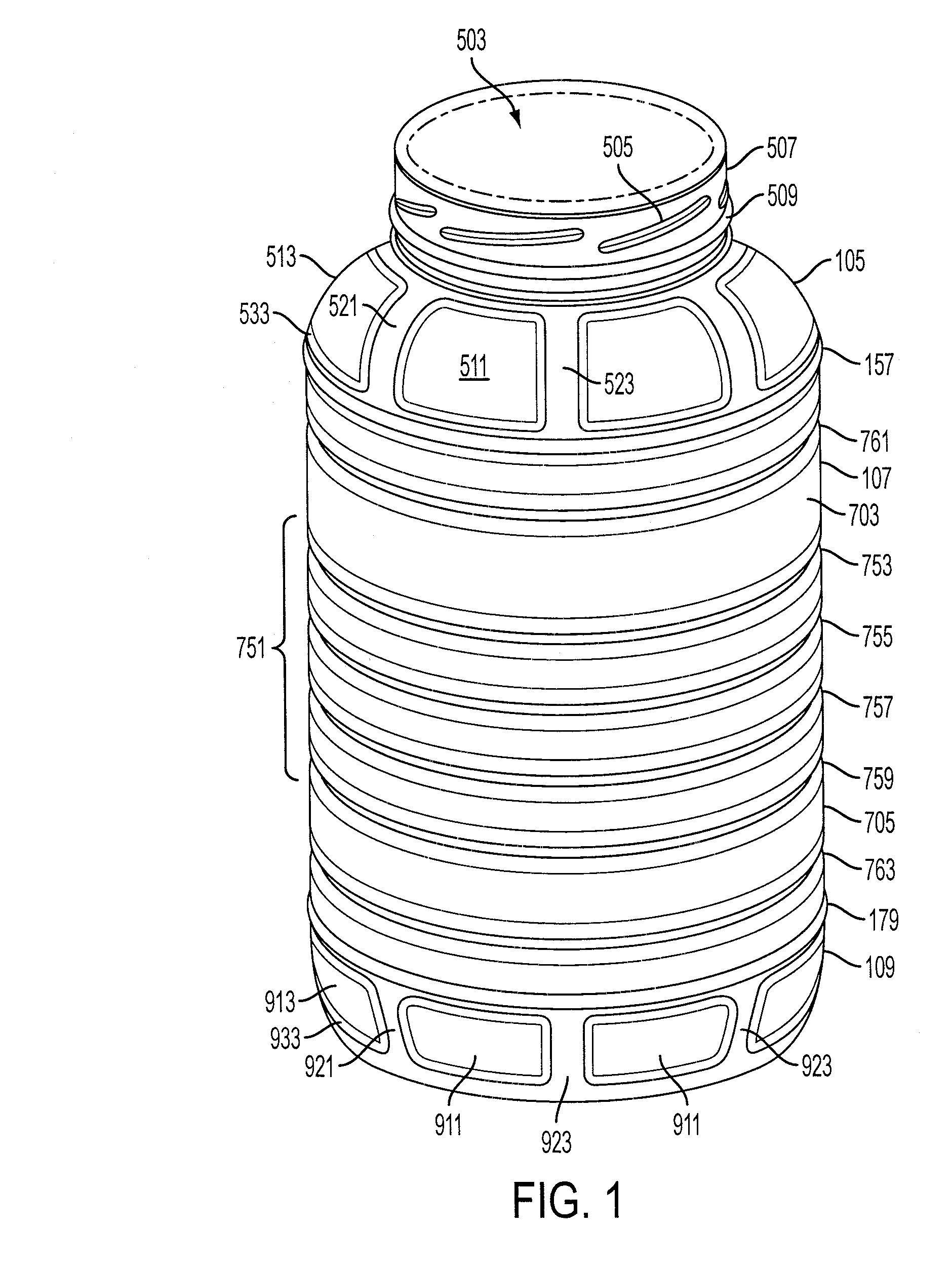

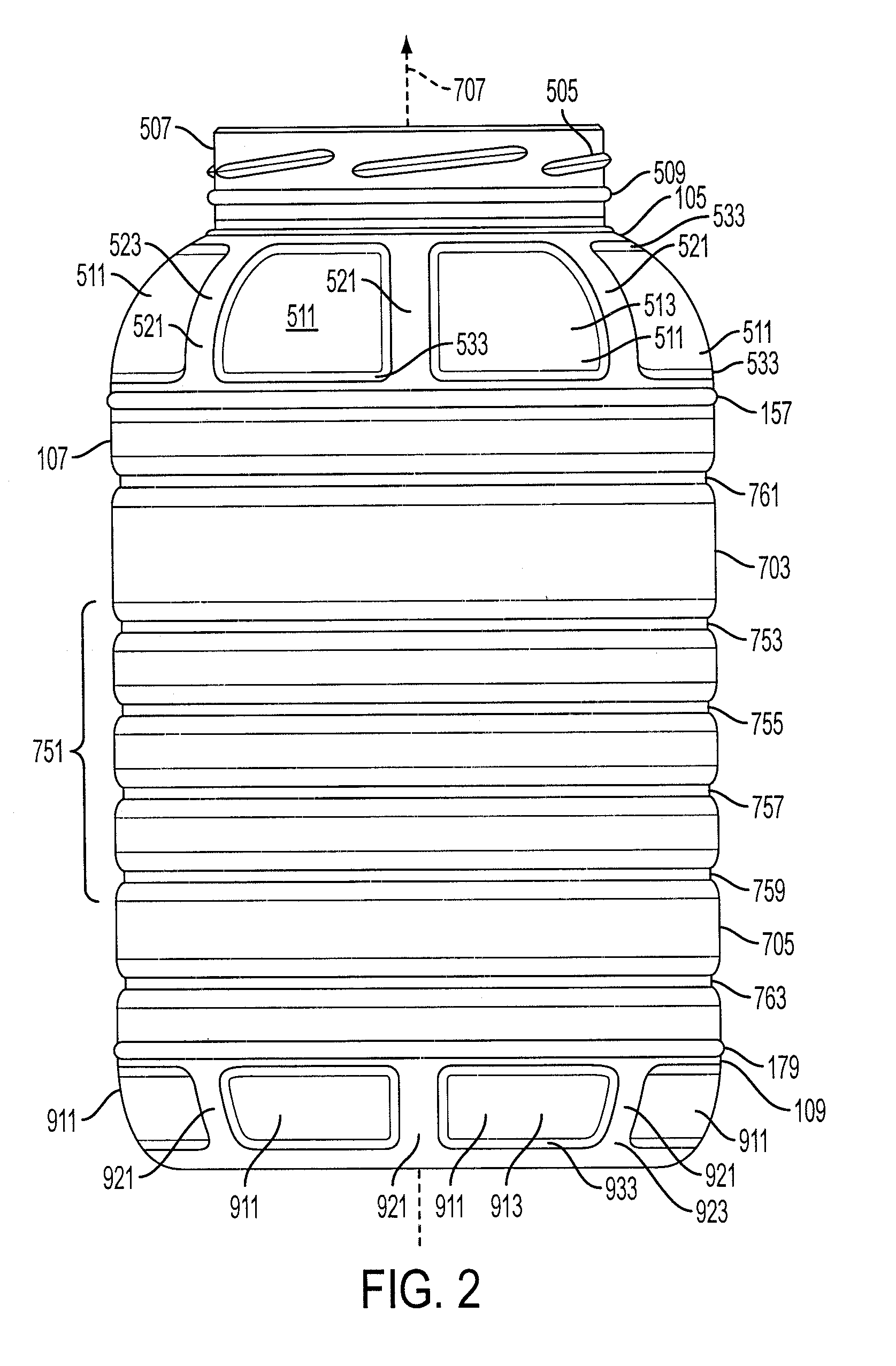

[0031]FIGS. 1 through 4 show a first embodiment of a container (100) designed to provide for improved crush resistance by including both the above devices. The container (100) in the depicted embodiment comprises a screw-top jar of generally barrel-shaped construction. This shape of jar is common in food service and other industries and is of the type often used for packaging flowable liquids or products including flowable liquids such as, but not limited to, pickled vegetables, fruits in syrup, mayonnaise, or mustard. There is no requirement that the container (100) be used for food service products and may be used for any type of product, but food service is a likely industry in which it would be useful. Additionally, there is no requirement that the container (100) be a jar having a screw-top lid or generally barrel-shape, the devices may be used on any container of any shape and having any sealing attachment. The screw top-lid and barrel-shape is, however, a popular general des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com