Liquid distributor and vertical tube falling film evaporator comprising same

A falling-film evaporator and liquid distributor technology, applied in vertical tube evaporators, evaporator accessories, evaporation, etc., can solve the problem that the cylinder cannot move, and achieve the effect of reducing deposition and reducing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

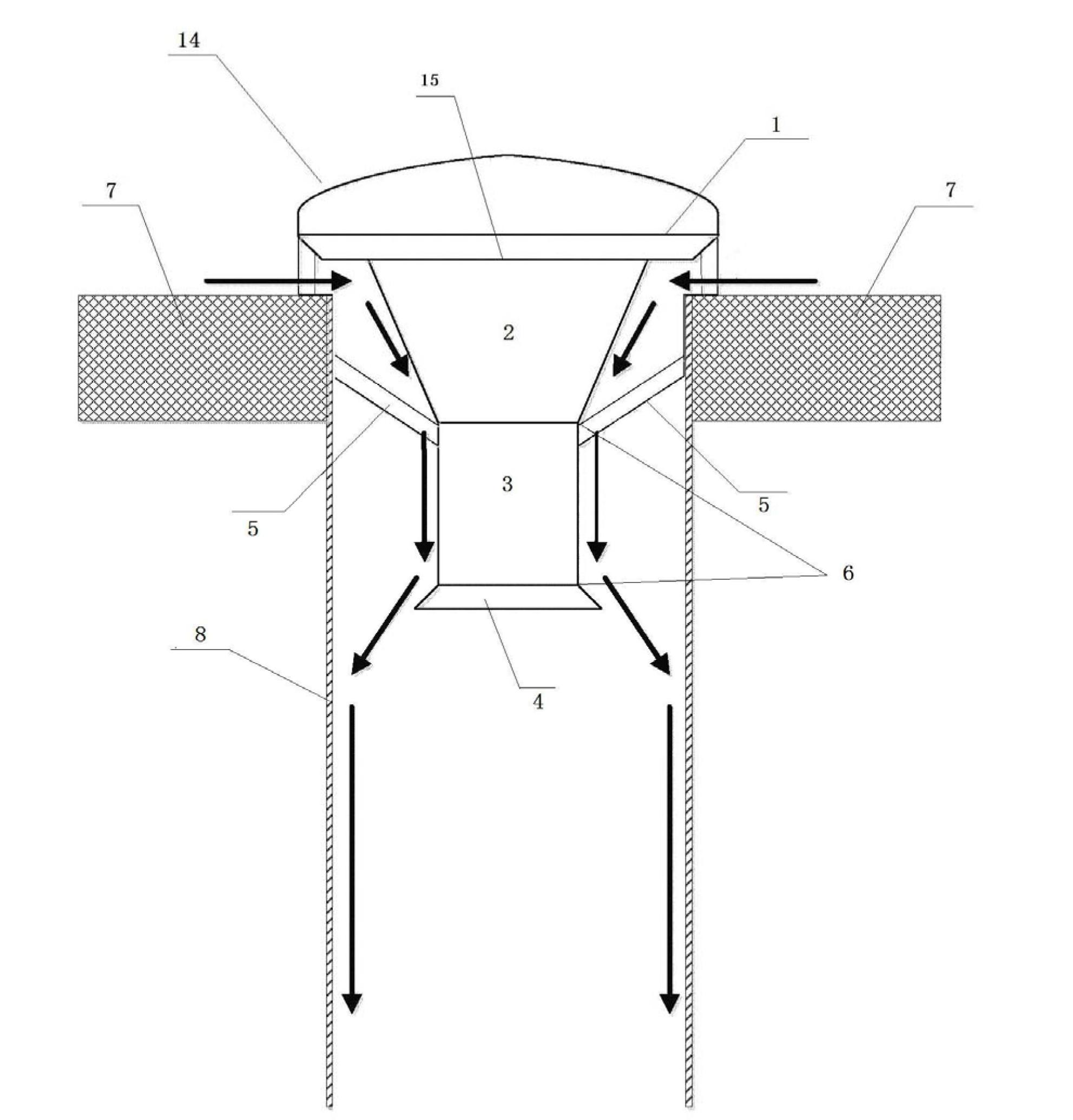

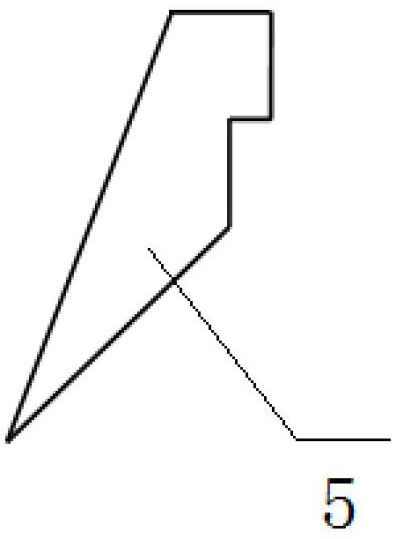

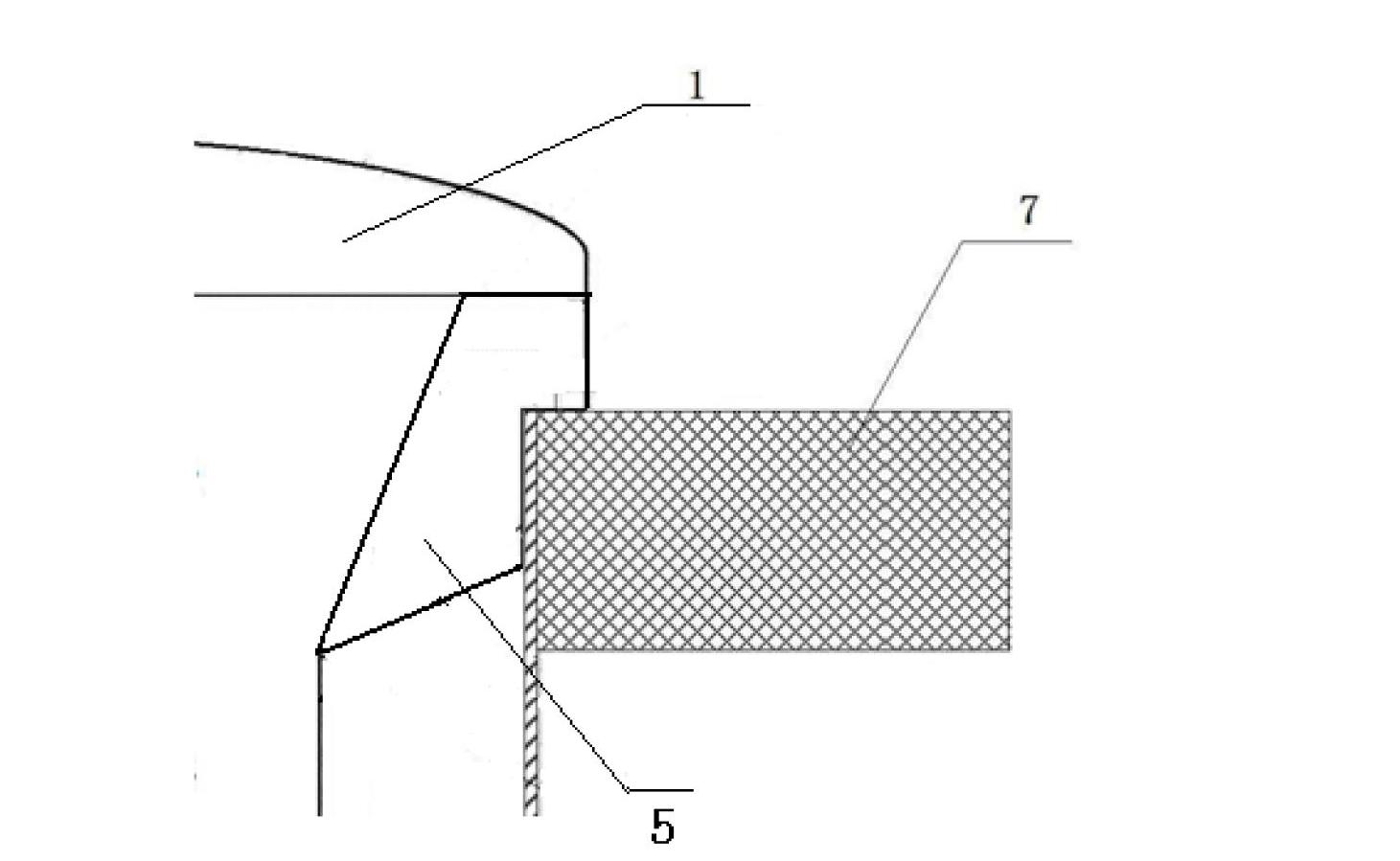

[0048] a kind of like figure 1 The liquid distributor 14 for the vertical tube falling film evaporator shown is mainly composed of a guide body 15 with a concave surface around the main body 6 and a bottom area of the top cover 1 larger than the area of the heat exchange tube 8 of the vertical tube falling film evaporator, and the The diversion body 15 is movably supported on the corresponding upper part of the heat exchange tube 8 of the vertical tube falling film evaporator, so that the edge of the bottom surface of the top cover 1 of the diversion body 15 and the upper surface of the tube sheet 7 of the vertical tube falling film evaporator are separated by a certain gap to form a gap. The support part 5 of the liquid channel is composed. The guide body 15 is symmetrically distributed along the central axis of the heat exchange tube of the vertical tube falling film evaporator, and consists of a main body 6 and a top cover 1 . The top cover 1 is cap-shaped, and its bot...

Embodiment 2

[0052] A sort of Figure 4 The shown liquid distributor 14 for the vertical tube falling film evaporator is mainly composed of a guide body 15 with a concave surface around it, and the guide body is movable supported and connected to the corresponding position in the upper part of the heat exchange tube 8 of the vertical tube falling film evaporator, and the guide body The upper surface of the fluid 15 is exposed to the support member 5 at the top of the heat exchange tube 8; the diameter of the upper surface of the guide body 15 is larger than the outer diameter of the heat exchange tube 8, so that the upper part of the concave surface of the guide body 15 (the part extending out of the heat pipe of the tube) ) edge and the top surface of the tube sheet 7 of the vertical tube falling film evaporator are separated by a certain gap to form a liquid inlet channel. The guide body 15 is symmetrically distributed along the central axis of the heat exchange tube 8 of the vertical tu...

Embodiment 3

[0056] a kind of like Figure 6 The liquid distributor 14 for the vertical tube falling film evaporator shown is mainly composed of a guide body 15 with a concave surface around the main body 6 and a bottom area of the top cover 1 larger than the area of the heat exchange tube 8 of the vertical tube falling film evaporator, and the The diversion body 15 is movably supported on the corresponding upper part of the heat exchange tube 8 of the vertical tube falling film evaporator, so that the edge of the bottom surface of the top cover 1 of the diversion body 15 and the upper surface of the tube sheet 7 of the vertical tube falling film evaporator are separated by a certain gap to form a gap. The support part 5 of the liquid channel is composed. The guide body 15 is symmetrically distributed along the central axis of the heat exchange tube 8 of the vertical tube falling film evaporator, and consists of a main body 6 and a top cover 1 . The top cover 1 is in the shape of a ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com