Raising membrane distributing water type evaporator

An evaporator and water-type technology, which is applied in the field of rising film water distribution evaporator, can solve the problems of evaporator evaporation energy reduction, energy waste, heat energy reduction, etc., and achieve heat utilization rate improvement, production cost reduction, and stable work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

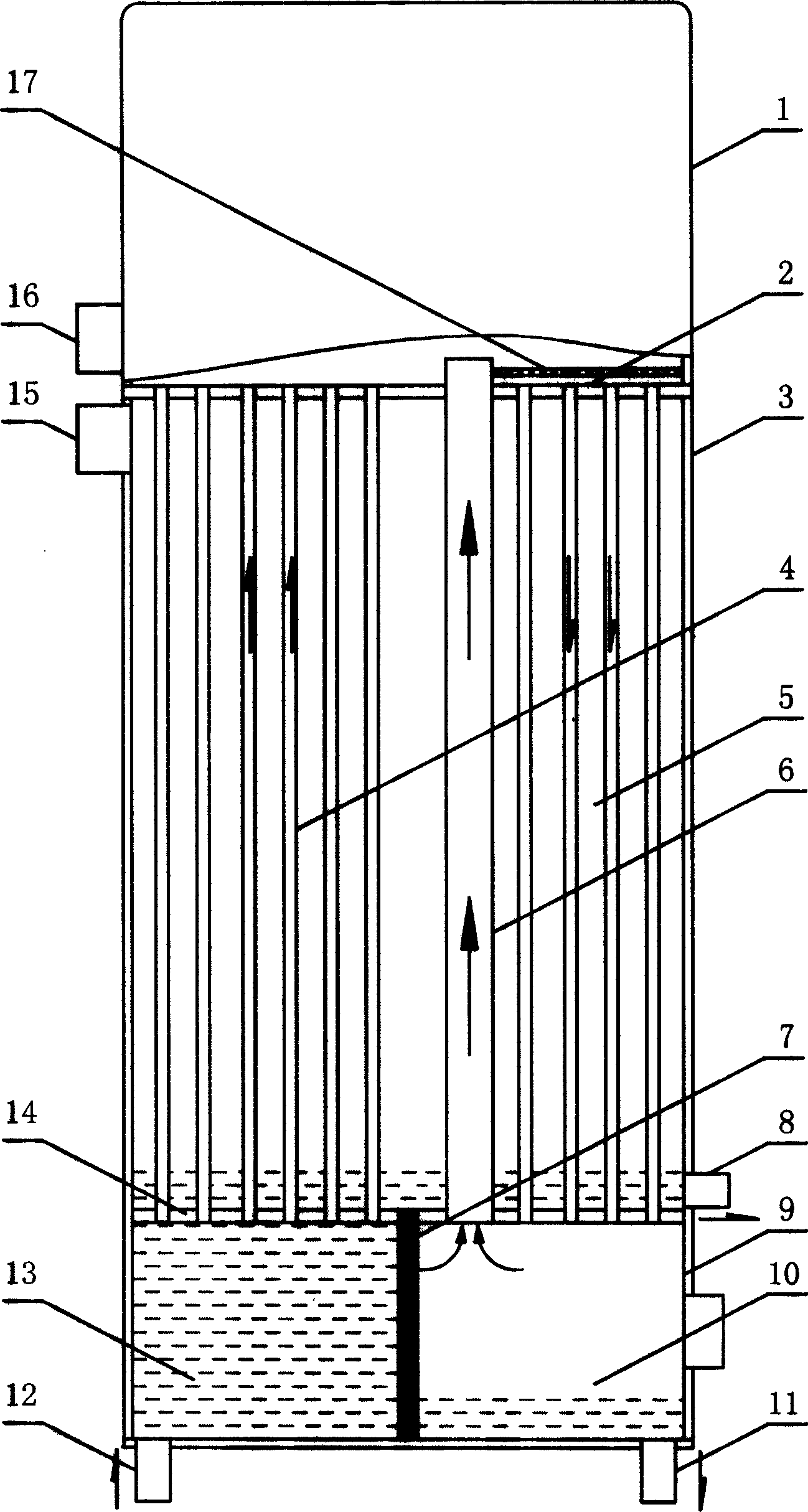

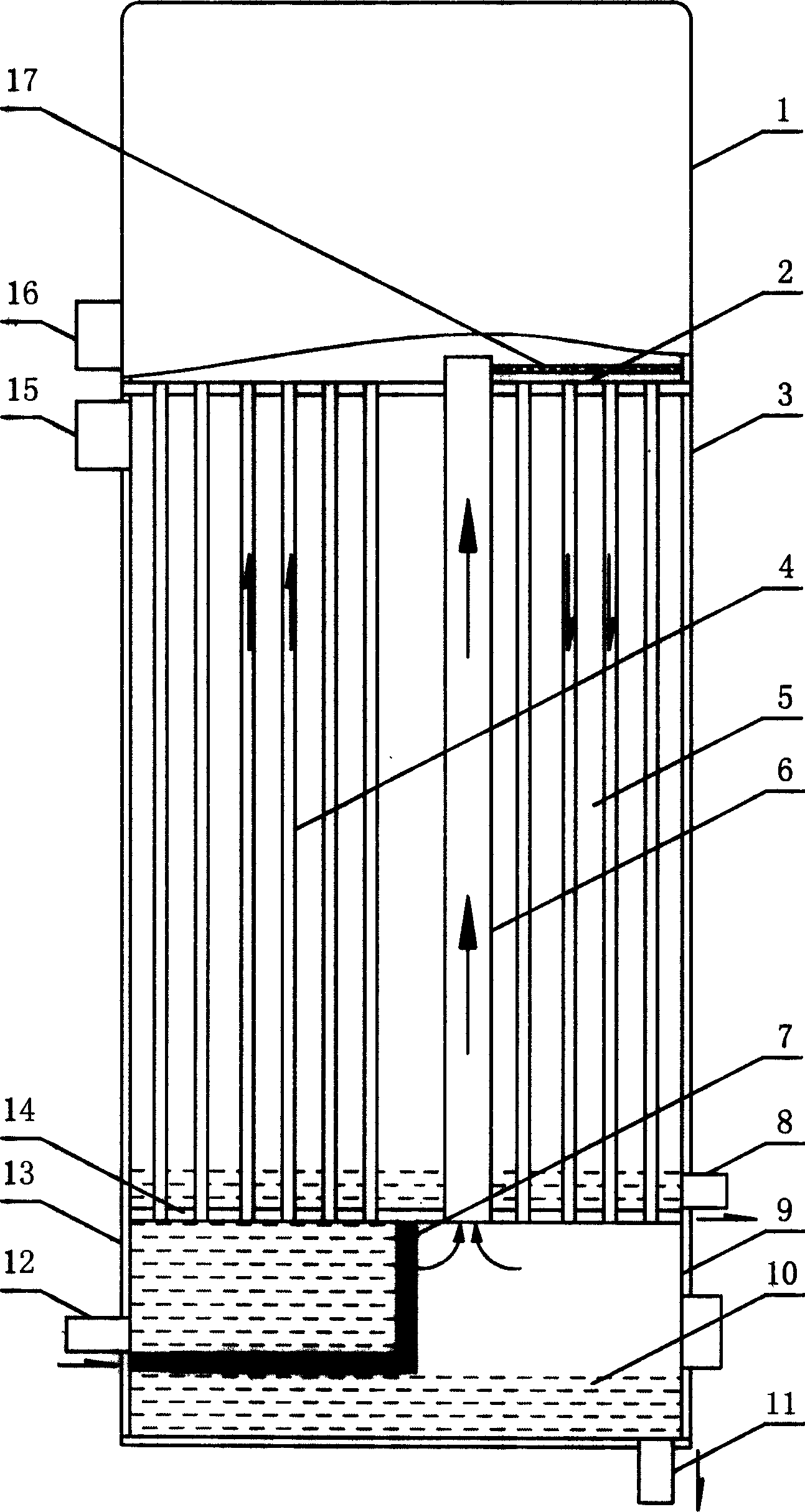

[0013] Before use, the figure 1 Or the multiple effects of the present invention shown in 2 are used in series to improve the production efficiency of distilled water.

[0014] When in use, inject high-temperature industrial steam into the evaporation chamber 5 of the evaporation section 3 through the steam inlet 15, and the high-temperature steam will quickly heat up the tubes 4 in the evaporation section 3, and at the same time, the raw material water passes through the rising film water chamber 13 The water inlet 12 enters the rising film water chamber 13, and quickly fills the rising film water chamber 13, because the raw material water rises at the same time at the same level, so it rises rapidly and evenly along the tubes 4 of each rising film part, And as it rises, it is vaporized in some of the tubes 4 of the rising film group, and the vaporized mixture of steam and water moves up quickly along the tubes 4, and the raw material water that is not completely vaporized en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com