Heat transferring tube for downward flow fluid membrane distiller

A heat transfer tube and liquid film technology, applied in vertical tube evaporators, evaporation, tubular elements, etc., can solve the problem of heat transfer performance reduction of heat transfer tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

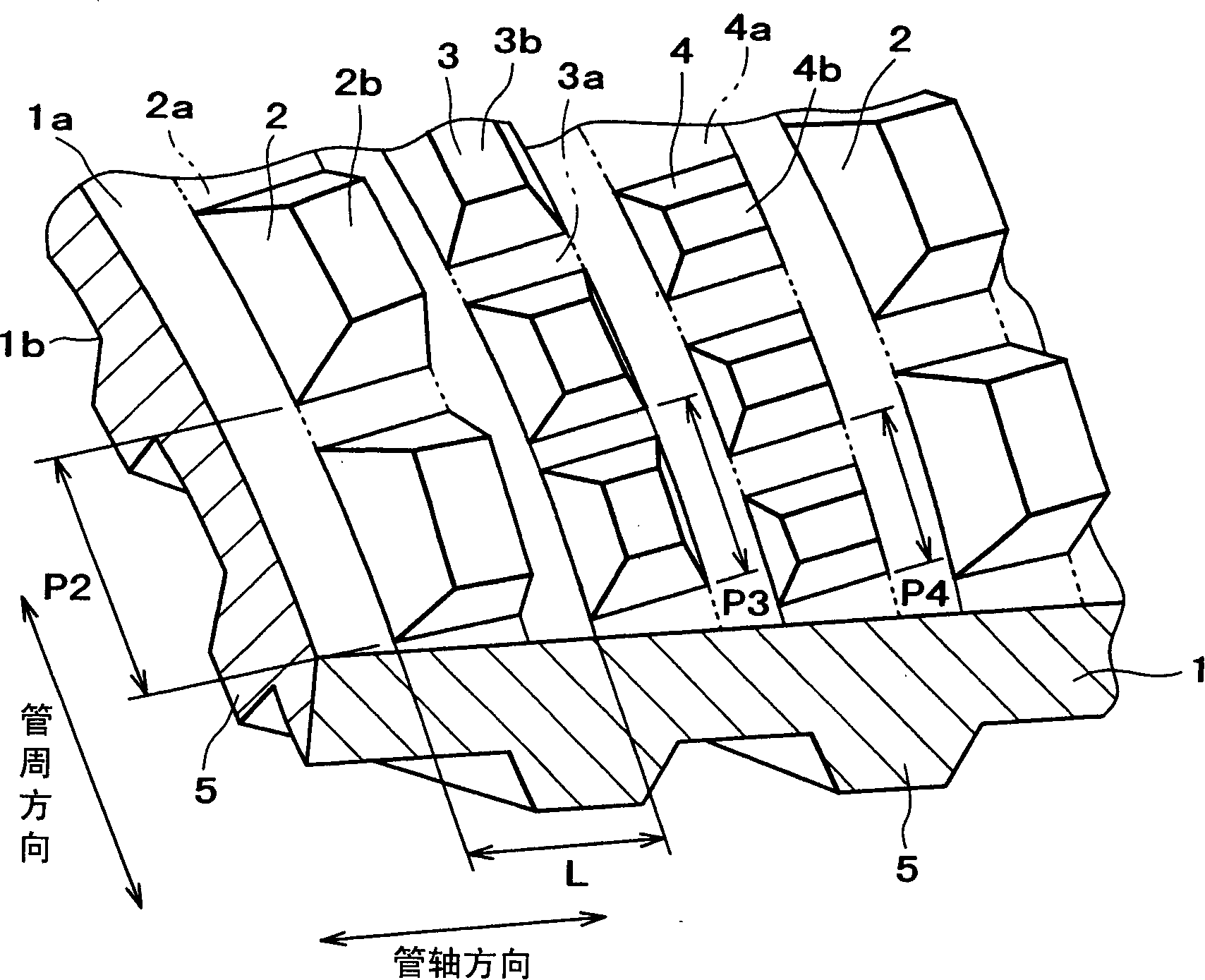

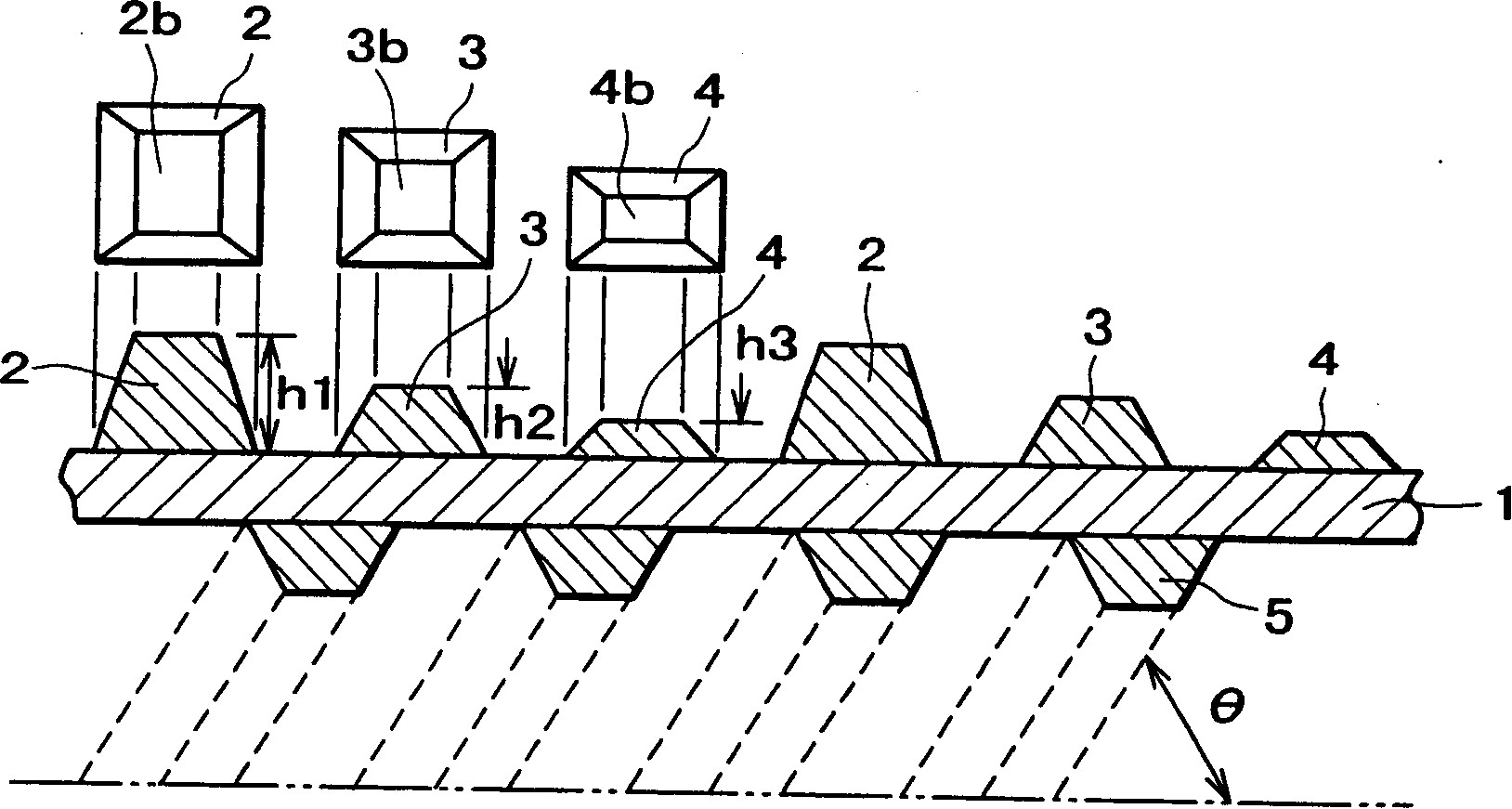

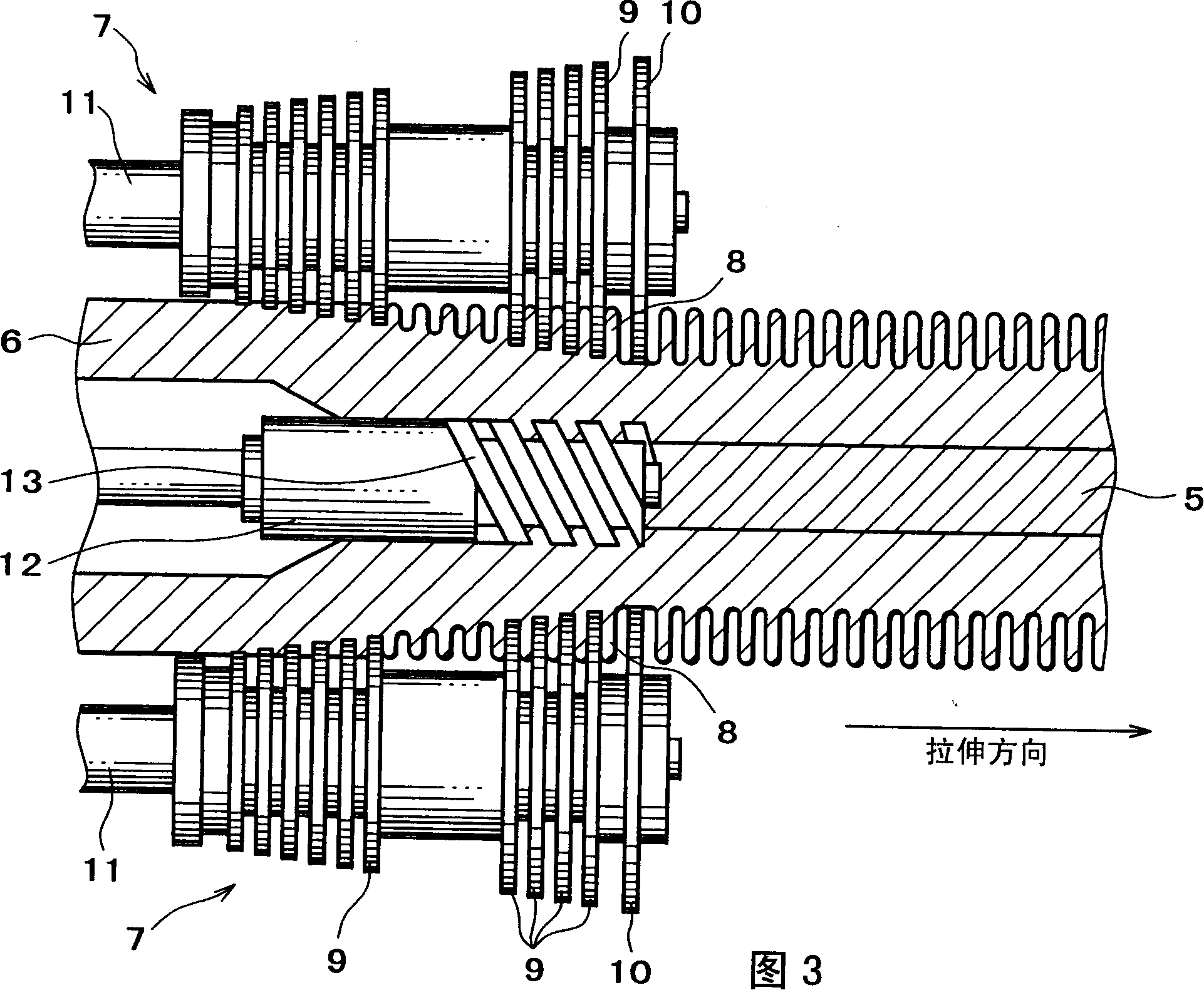

Method used

Image

Examples

Embodiment

[0055] Next, the effects of the embodiments of the present invention will be specifically described in comparison with comparative examples outside the scope of the claims. First, a test method common to each of the following test examples will be described. First, a method of measuring the overall heat transfer coefficient of the heat transfer tube as the heat transfer performance of the heat transfer tube will be described. Figure 4 It is a schematic diagram showing the configuration of the test apparatus used in the heat transfer tube performance evaluation tests of Examples and Comparative Examples of the present invention.

[0056] Such as Figure 4 As shown, a chamber 14 is provided in this test device, and the interior of the chamber 14 is divided into two chambers of an evaporator 14 a and an absorber 14 b by a partition wall 15 . In addition, steam may flow through the upper portion of the partition wall 15 . In the evaporator 14a, six heat transfer tubes 16 are v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com