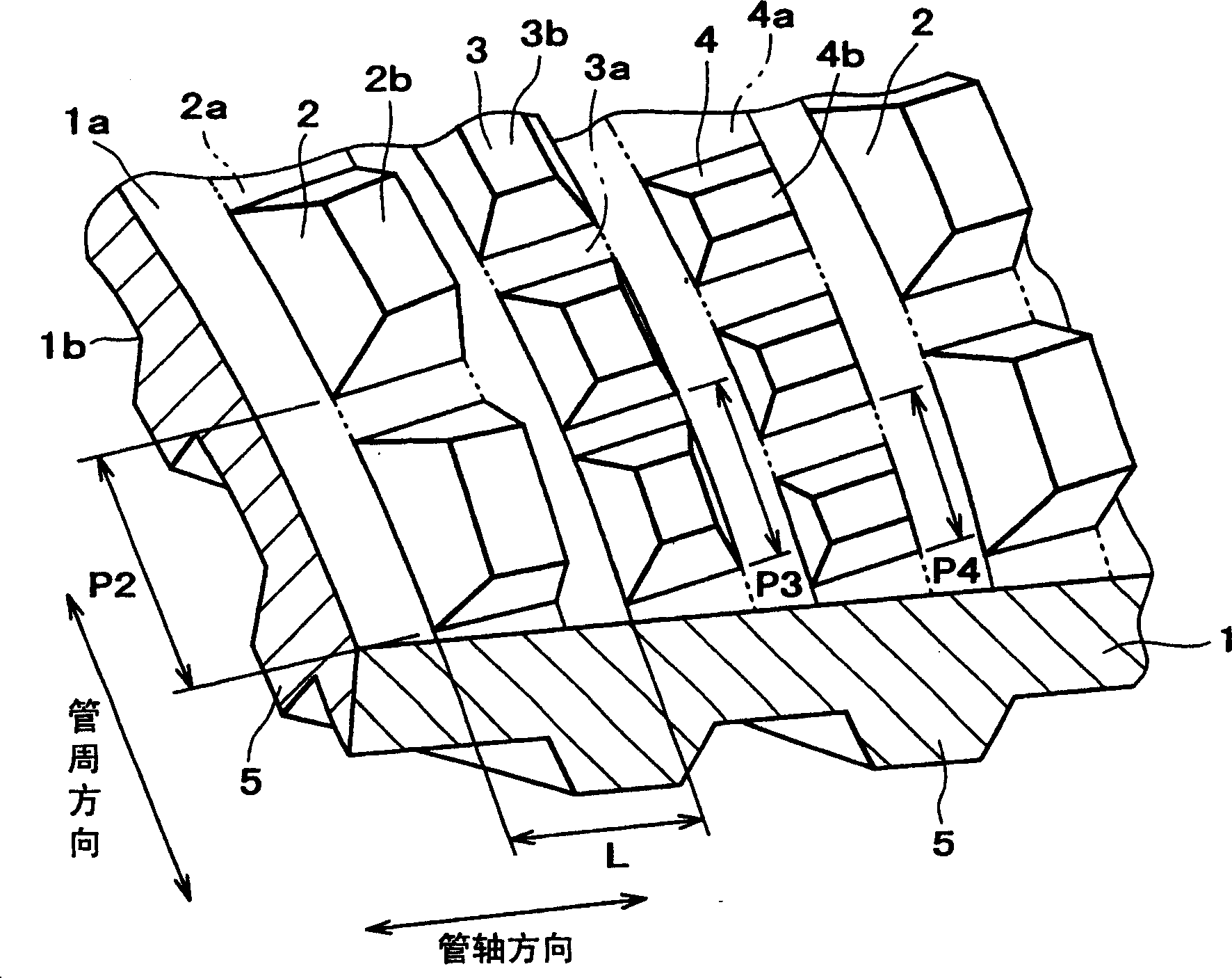

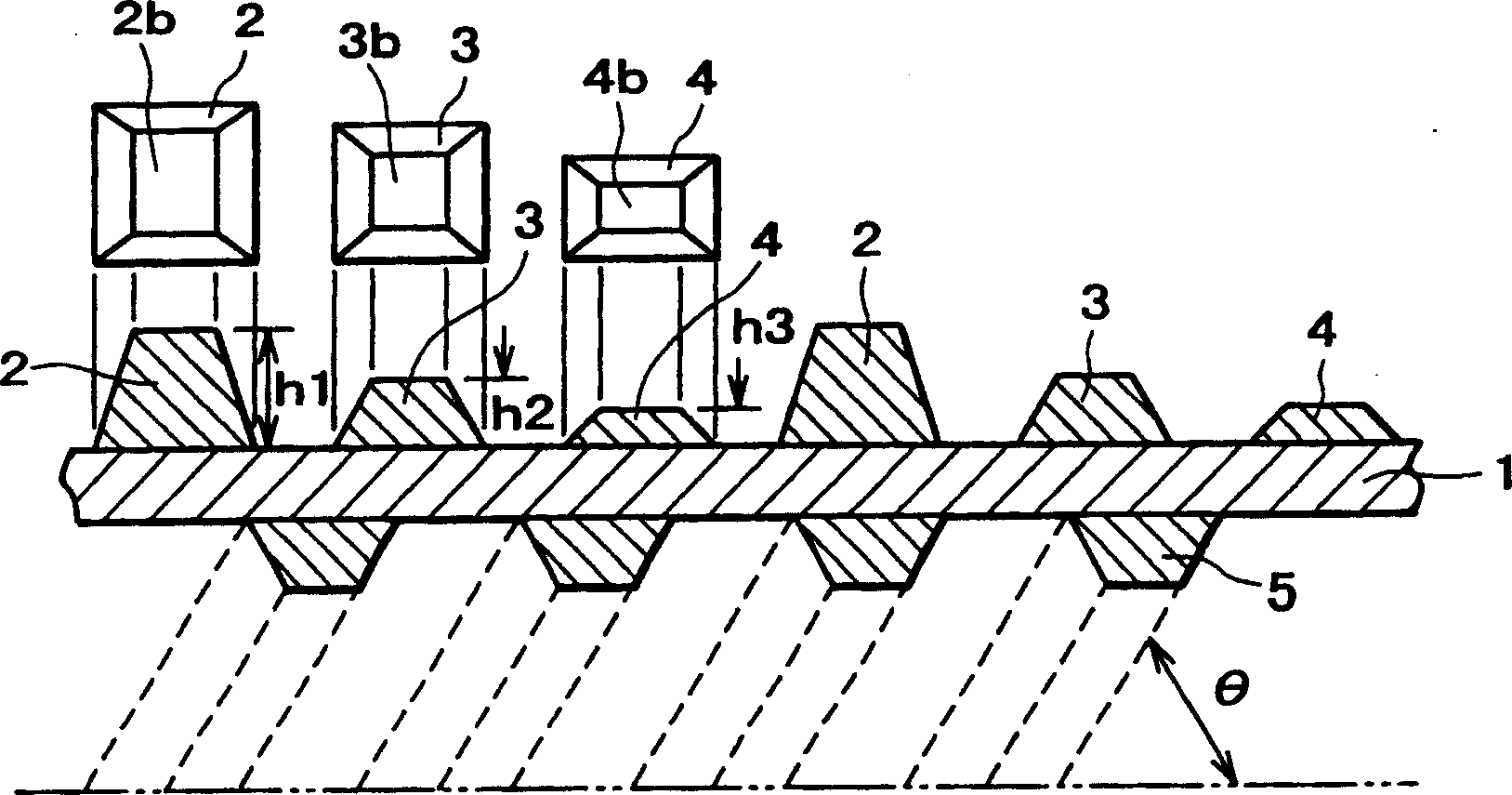

Heat transferring tube for downward flow fluid membrane distiller

A heat transfer tube and liquid film technology, which is applied in vertical tube evaporators, evaporation, tubular elements, etc., can solve the problems of reduced heat transfer performance of heat transfer tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

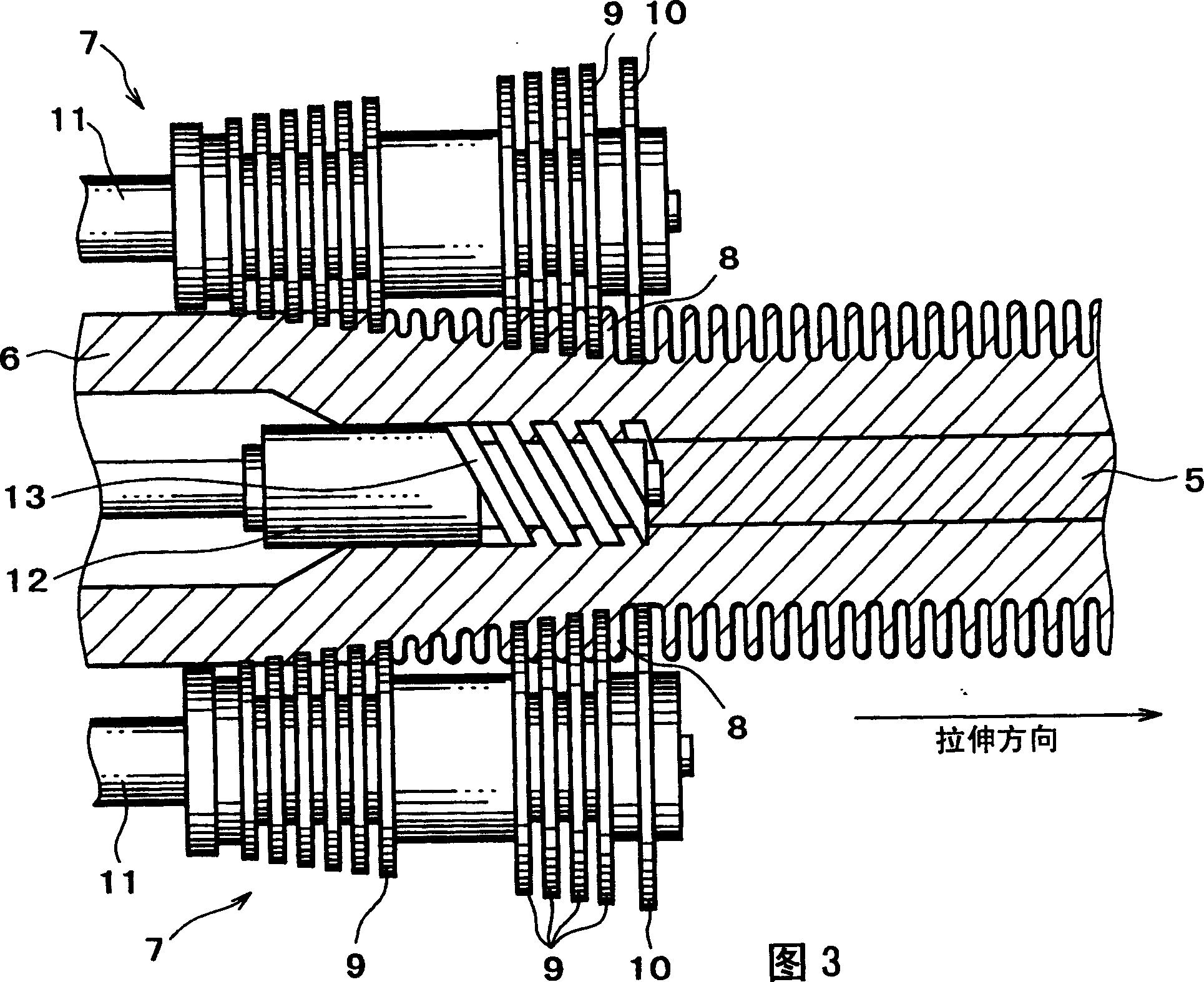

Method used

Image

Examples

Embodiment

[0055] Hereinafter, the effect of the embodiment of the present invention will be specifically described in comparison with comparative examples outside the scope of the claims. First, the test methods common to the following test examples will be explained. First, the method of measuring the total heat transfer coefficient of the heat transfer tube as the heat transfer performance of the heat transfer tube is explained. Figure 4 It is a schematic diagram showing the configuration of the test device used in the heat transfer tube performance evaluation test of the embodiment of the present invention and the comparative example.

[0056] Such as Figure 4 As shown, a cavity 14 is provided in the test device, and the inside of the cavity 14 is divided by a partition wall 15 into two chambers of an evaporator 14a and an absorber 14b. In addition, steam can flow through the upper portion of the partition wall 15. In the evaporator 14a, the four heat transfer tubes 16 are arranged in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com