Methods of storing and moving proppant at location adjacent rail line

a technology of proppant and rail line, applied in the direction of stacking articles, liquid handling, ways, etc., can solve the problems of increasing the demand for proppant, increasing so as to reduce the risk of damage to the proppant supplier, the effect of reducing driver fatigue and enhancing the productivity of the proppant supplier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

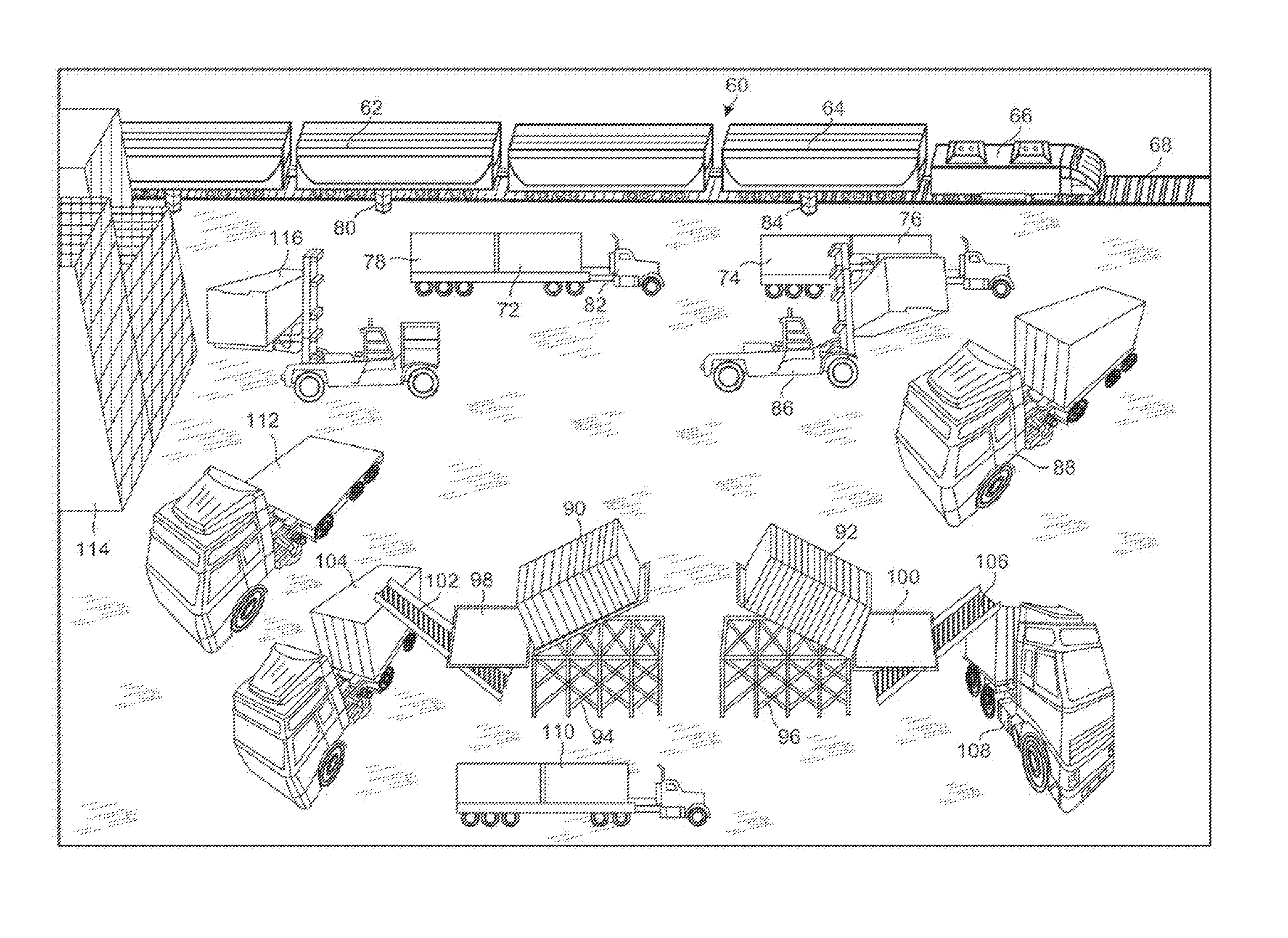

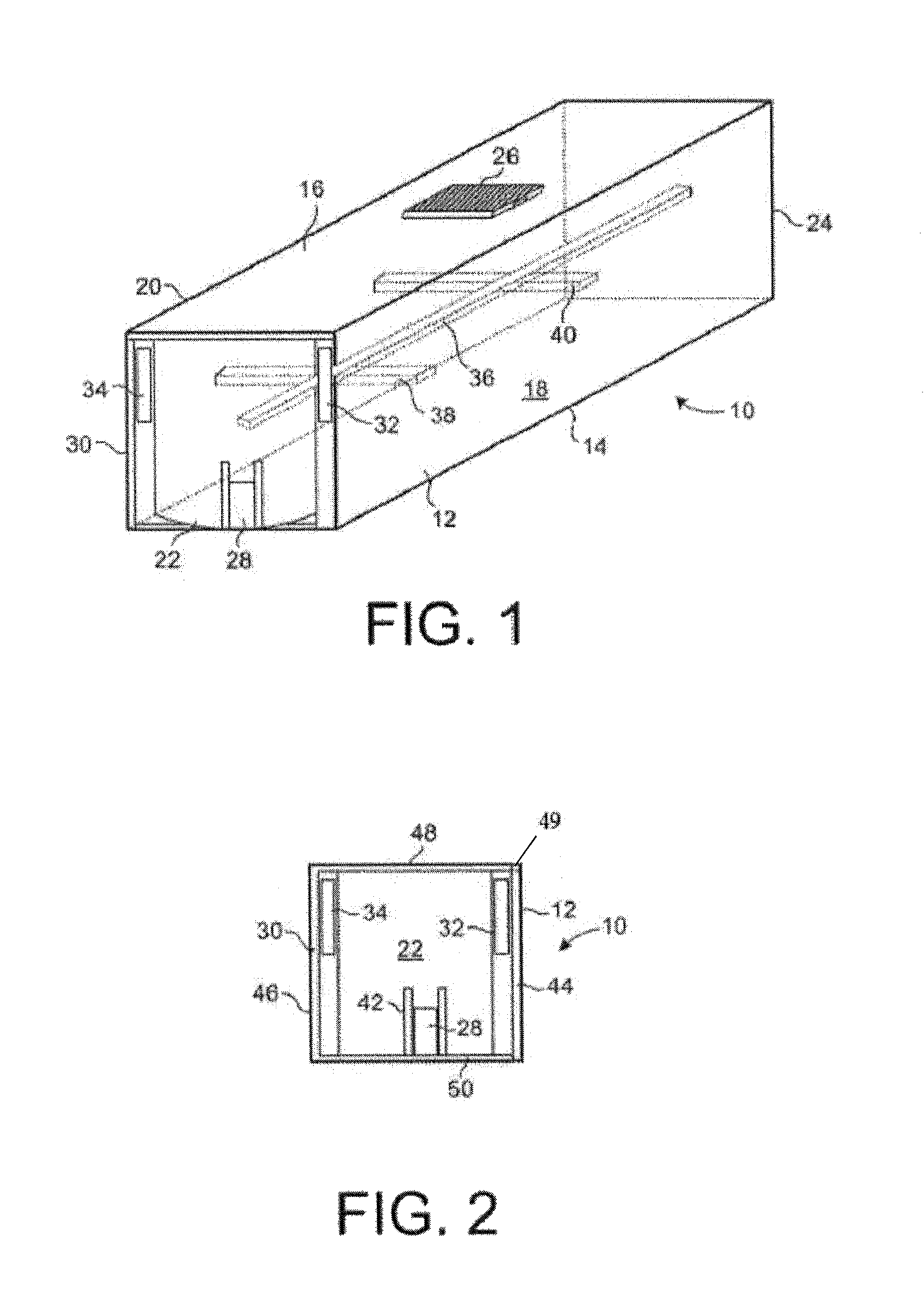

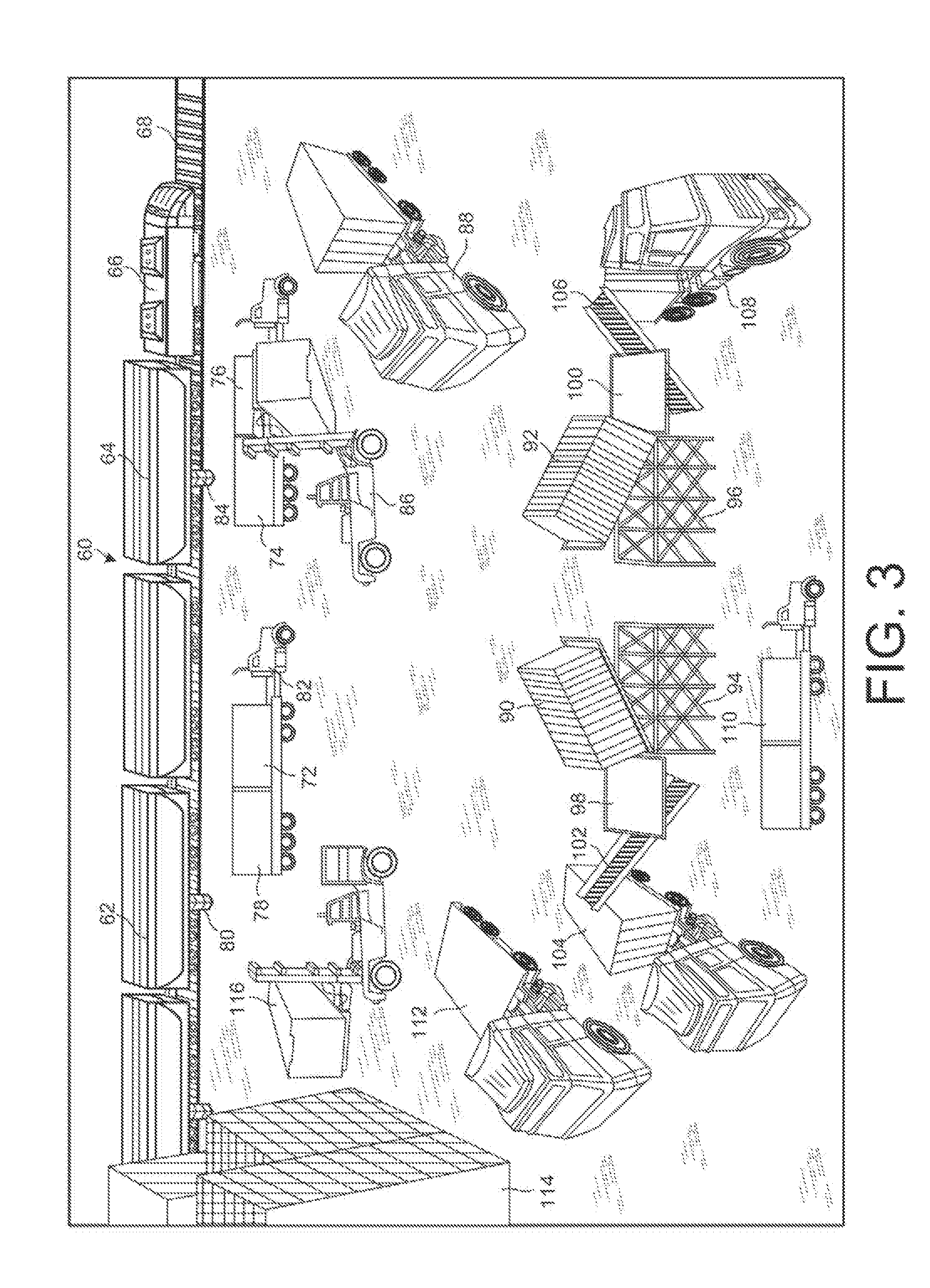

[0047]Referring to FIG. 1, there is shown the proppant storage apparatus 10 in accordance with the preferred embodiment of the present invention. The proppant storage apparatus 10 includes a container 12 having a bottom wall 14, a top wall 16, a pair of side walls 18 and 20 and a pair of end walls 22 and 24. The side wall 18 extends between the bottom wall 14 and the top wall 16. The side wall 20 also extends between the bottom wall 14 and the top wall 16 in generally spaced parallel relationship to the side wall 18. The end wall 22 extends between the bottom wall 14 and the top wall 16. Similarly, the end wall 24 extends between the bottom wall 14 and the top wall 16 and also between the side walls 18 and 20. The top wall 16 has a hatch 26 formed thereon. Hatch 26 is openable so as to allow proppant to be introduced into the interior volume of the container 12. A flow gate 28 is positioned on the end wall 22. The flow gate 28 is openable so as to allow the proppant to flow outwardl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com