Automatic feeding equipment for samples

An automatic feeding and sample technology, applied in the direction of emptying containers, loading/unloading, bottle filling, etc., can solve the problems of endangering the health of operators, affecting the overall operation of the system, and easily causing dust, so as to avoid unstable operation of equipment , to meet the effect of continuous operation and operation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

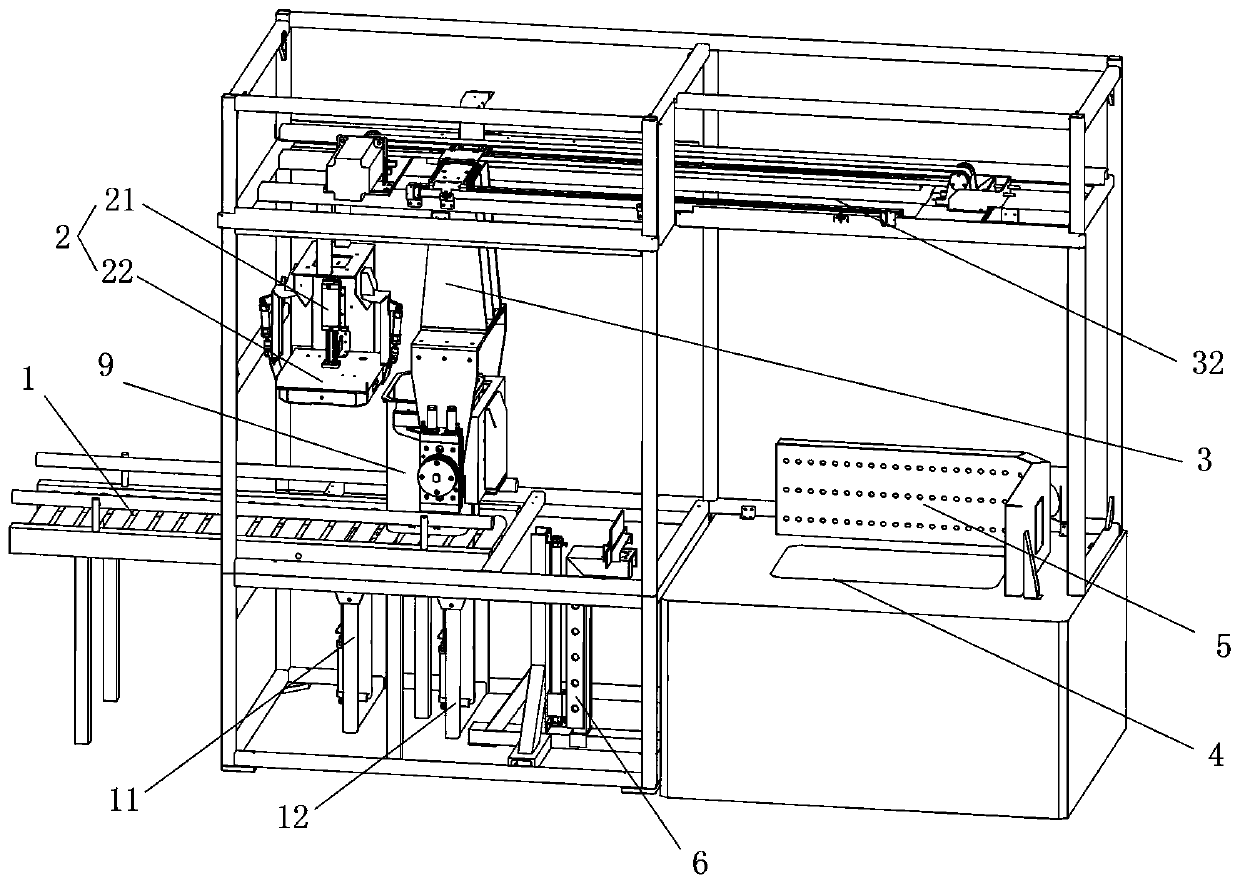

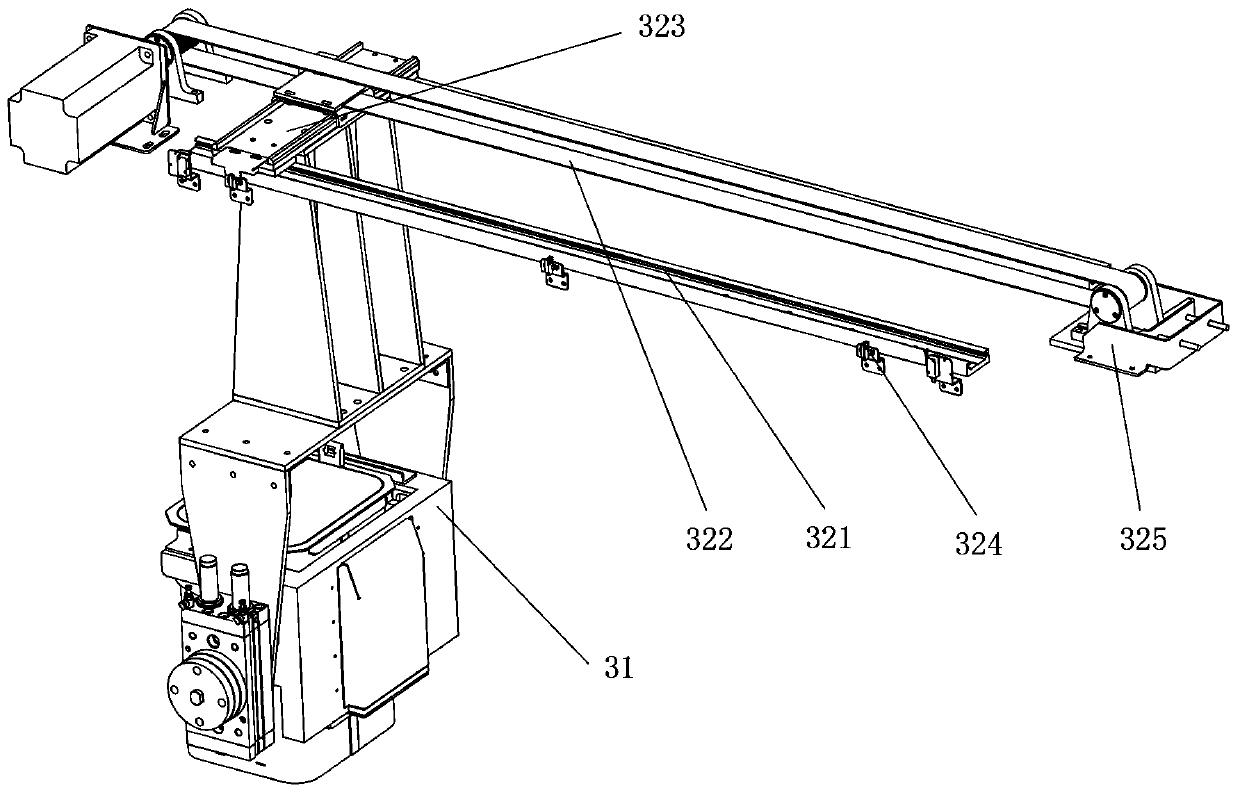

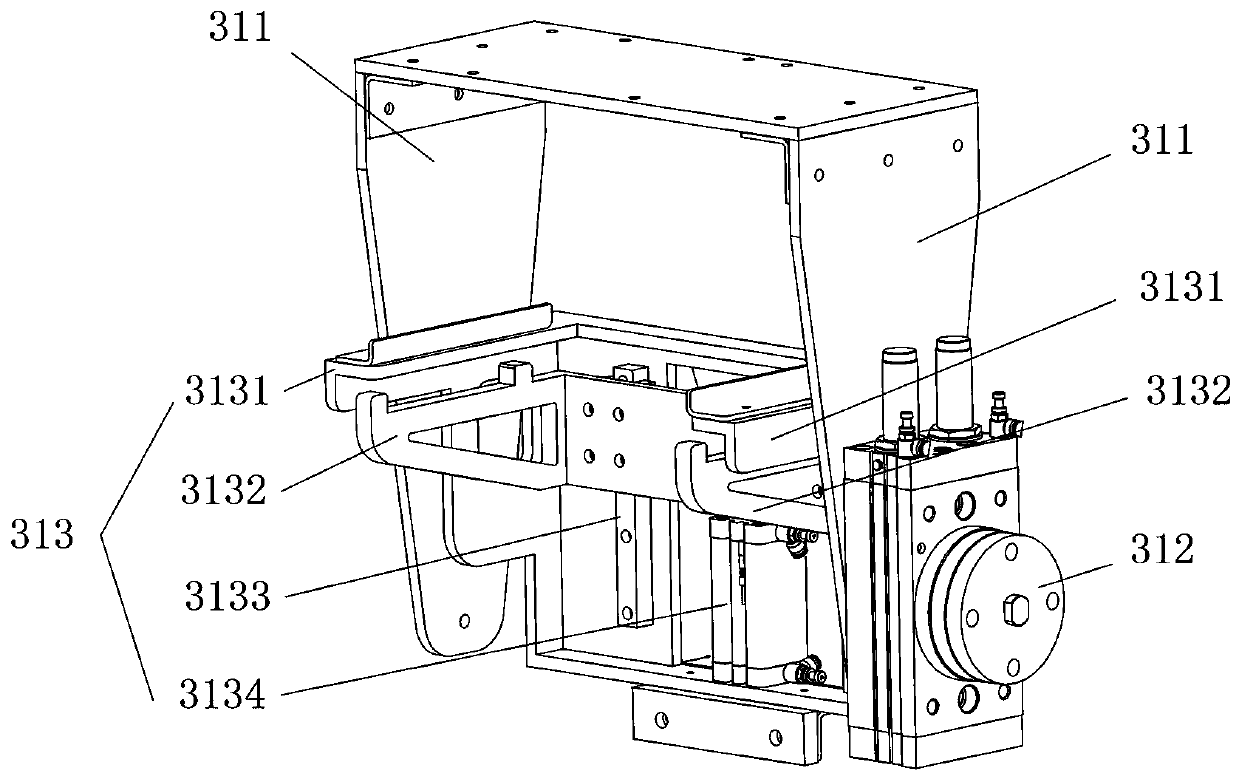

[0043] Such as Figure 1 to Figure 6 As shown, the present invention provides a kind of automatic feeding equipment for sample, comprises the conveying line device 1 that is used to transmit sample barrel 9, and conveying line device 1 is installed on the transmission line frame, and the initial end of conveying line device 1 can be connected with The relevant equipment of the sampling and preparation system is flexibly connected, and is used to quickly transfer the sample barrel 9 containing the material to the conveying line device 1 for loading. Loading station 4 can be equipped with a hopper, or a feeding transmission line, or other related equipment of the sampling and preparation system for automatic docking, so that the materials that are turned over and dumped by the sample bucket 9 are all unloaded on the hopper, or the feeding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com