High-speed train express mail logistics system

A logistics system and express mail technology, which is applied in logistics, emptying containers, instruments, etc., can solve the problems that high-speed rail cannot transport express mail, and achieve the effects of high automation, improved efficiency and accuracy, and optimized layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

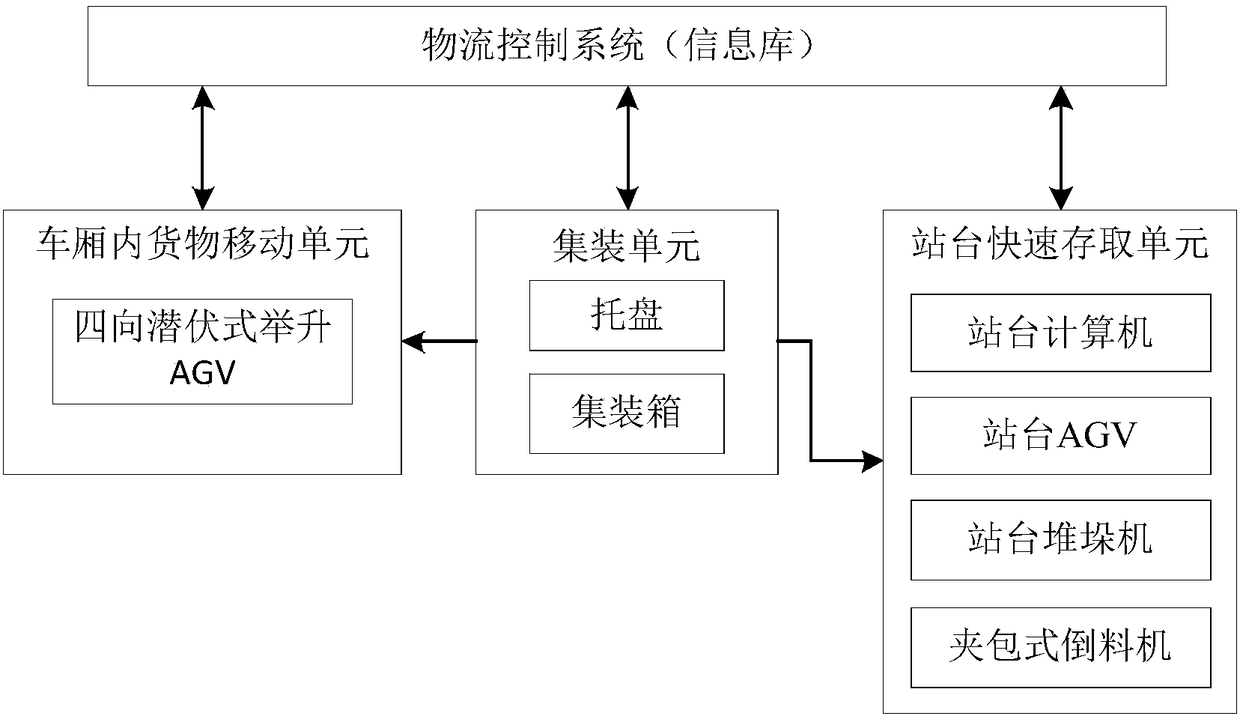

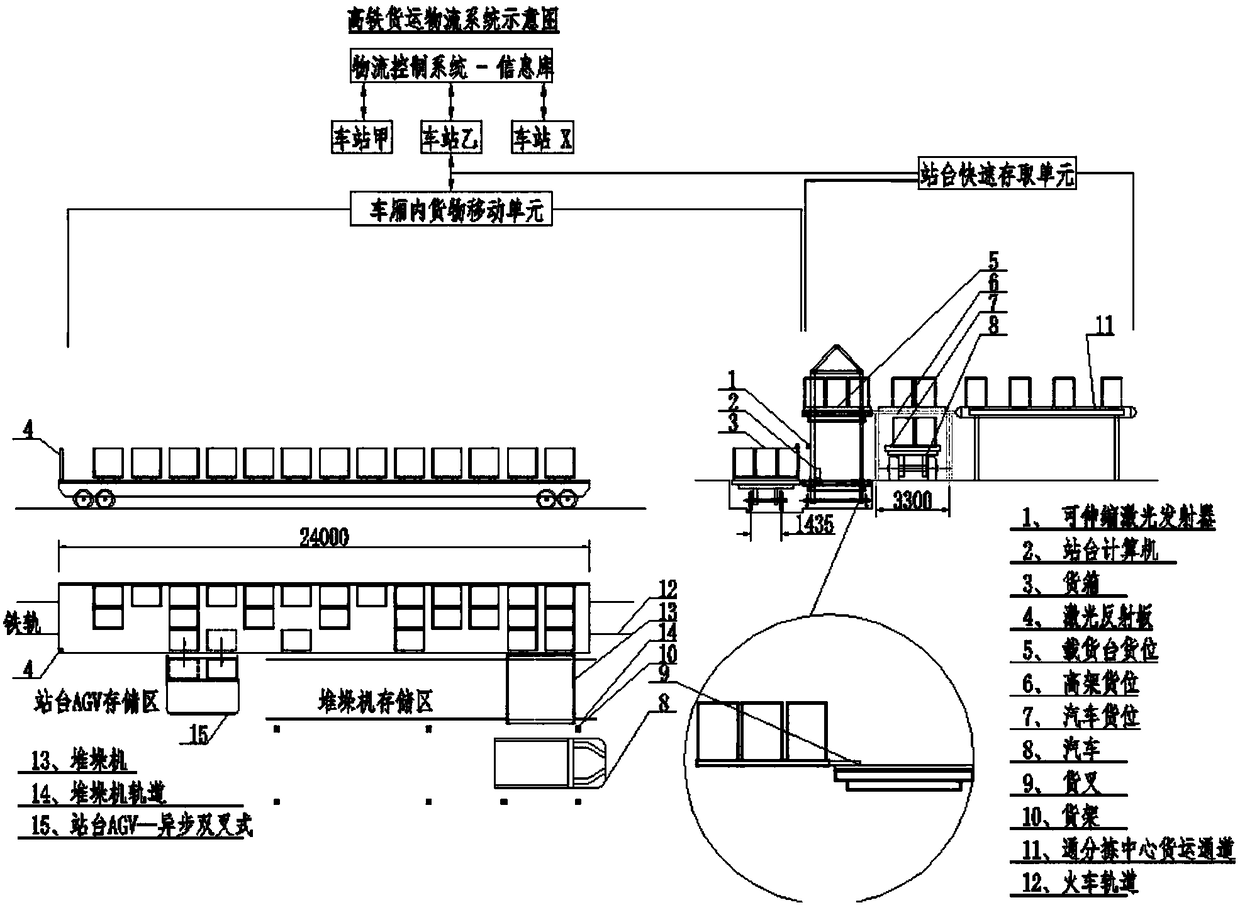

[0036] figure 2 It is a schematic structural diagram of the high-speed rail express logistics system of the present invention, and the operating process of the structure is as follows:

[0037] There is a positioning block 26 on the transition pallet 22 under the container unit 31 for loading goods. The initial position of the container unit 31 is specified by the information base. The intelligent robot moves the container unit 31 in the compartment and scans its barcode to confirm the new location. The on-board controller of the intelligent robot sends the location information to the information database of the logistics control system in real time, and the information database transmits the location information of the loading and unloading positions of the trucks to the platform computer 2 in real time through wired or wireless. When the cargo compartment is about to stop at the platform, the stacker 13 moves to the predicted loading and unloading position of the correspond...

Embodiment 2

[0043] image 3 It is a schematic diagram of the latent lifting AGV (intelligent robot) 23 of the present invention, and the operating process of the structure is as follows:

[0044] Described intelligent robot is four-way latent type lifting AGV (intelligent robot) 23, comprises: car body, vehicle-mounted controller, lifter 24, four-way wheel 25; Latent type lifting AGV (intelligent robot) 23, can The container unit or the existing container 21 of the railway and its transition pallet 22 move under it, and the four-way wheels 25 controlled by the computer travel in four directions at the bottom of the container unit in the carriage. The logistics control system sets virtual grid coordinates in the compartment, and uses the coordinates (X, Y) (X, Y are natural numbers) to represent the position of the goods in the compartment. According to the information base, the intelligent robot sends the cargo information that needs to be loaded and unloaded at the downlink station, the...

Embodiment 3

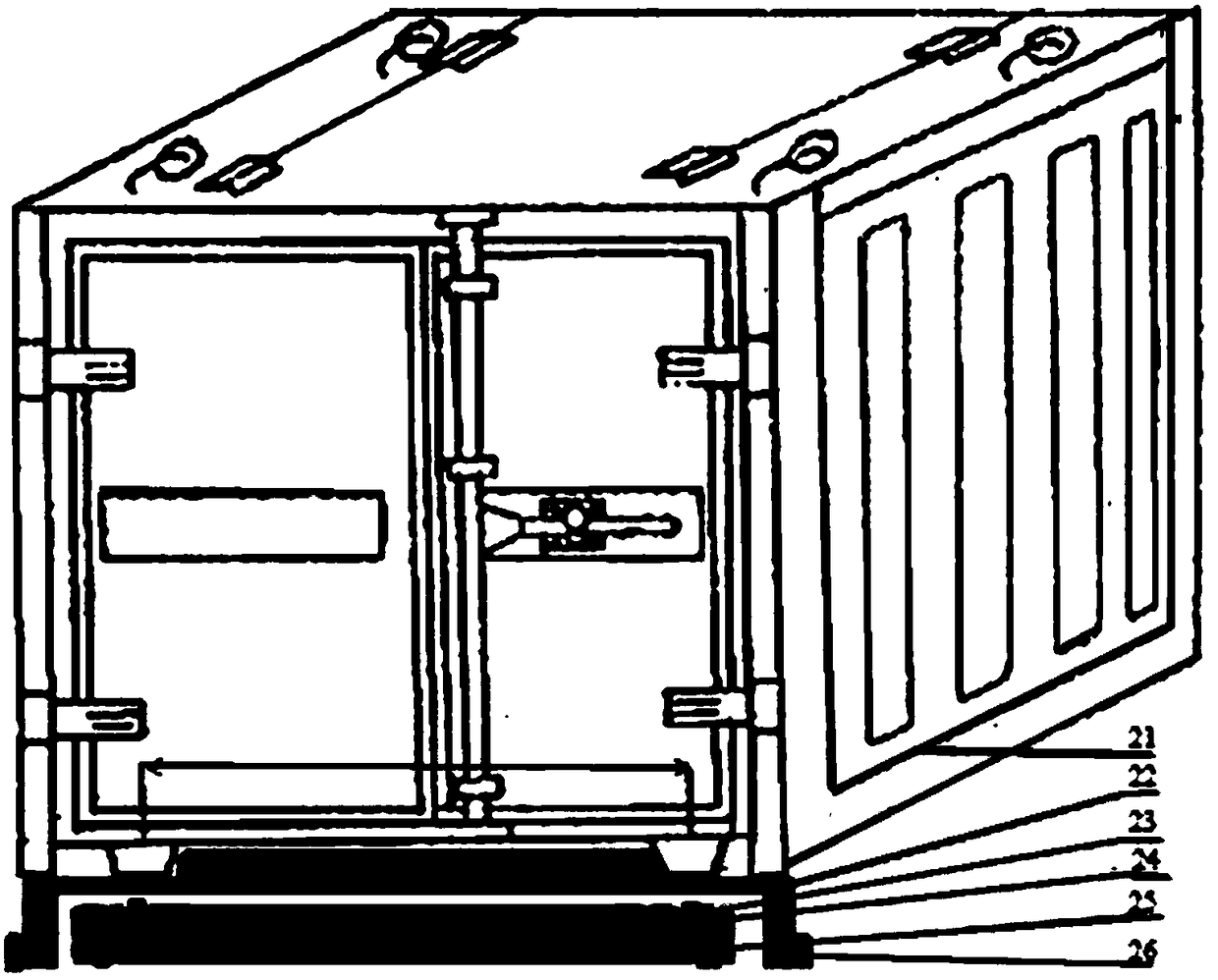

[0047] Figure 4 is a schematic diagram of the container unit of the present invention, Figure 5 It is a schematic diagram of the work of the bag-type dumping machine 41 of the present invention, and the structural operation process is as follows:

[0048] The light container is suitable for air-land transport and is made of new light materials, including: a box body, a reinforcement belt 32, a linkage door 33, a gear 45 for controlling the linkage door, a transition tray 22 at the bottom of the box, and a positioning block 26; The unloading machine includes: frame, double arm 42, bracket 43, gear 44 and small motor; reinforcement belt 32 is located on both sides of the light container, linkage door 33 linkage door adopts oblique configuration, and is connected with the gear, and the linkage can be controlled by turning the gear Door switch angle; the transition tray 22 is located at the bottom of the box, with a certain distance between the middle and the ground, which is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com