Opposite roller type flexible spinning alternating current servo direct drive structure

An AC servo and direct drive technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as difficult expansion of processing range, difficulty in adjustment of internal rotation wheel, difficulty in large-scale application, etc., to achieve strong modeling ability and simple The effect of large modeling and processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

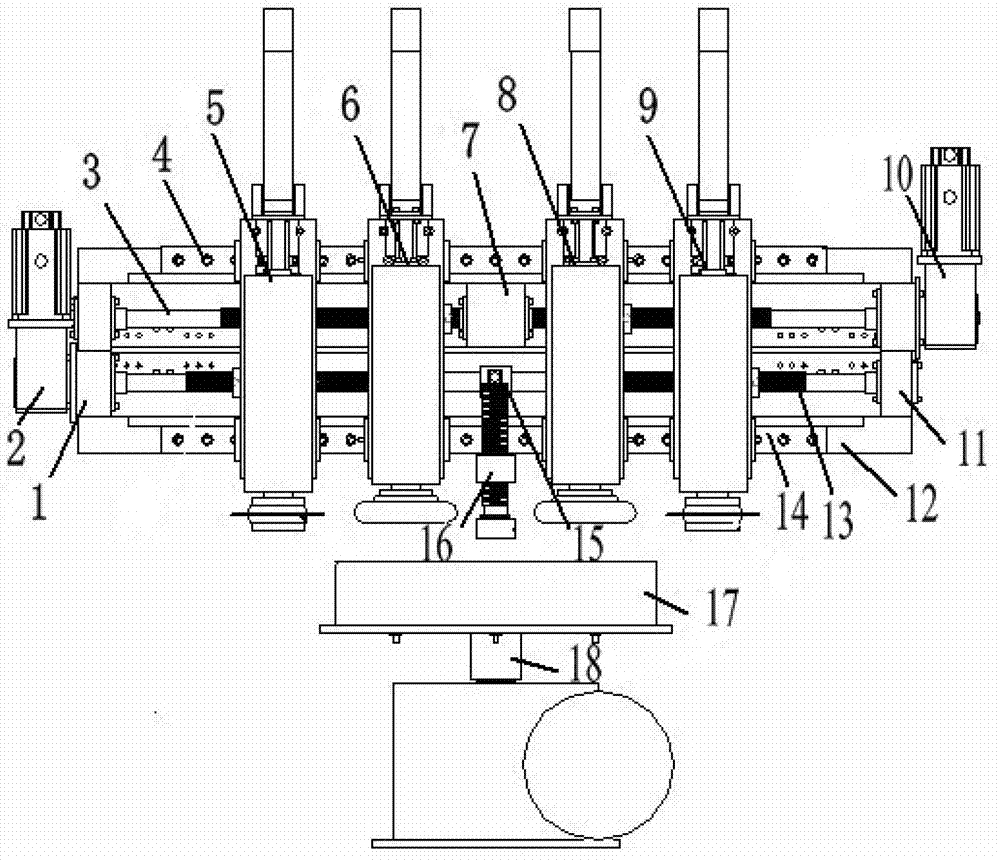

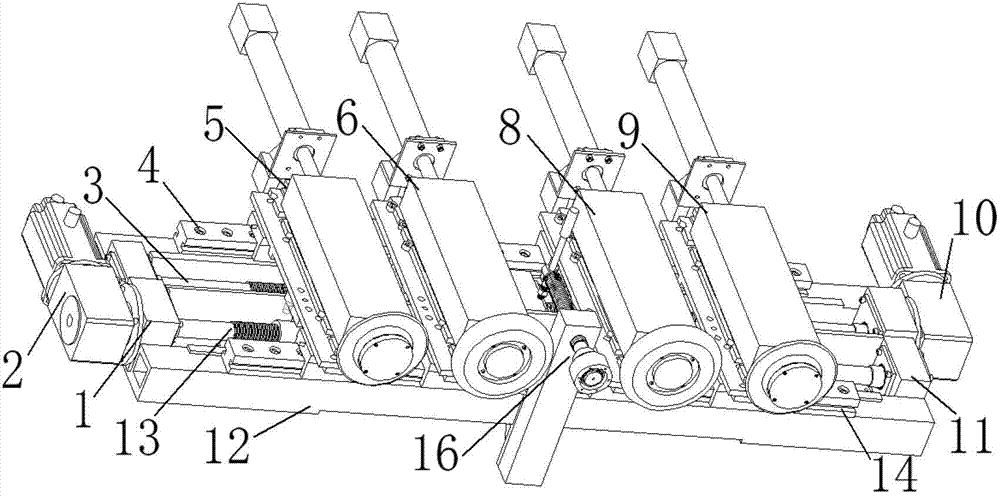

[0028] refer to figure 1 with figure 2 , an AC servo direct drive structure for wheel-type flexible spinning, including a first inner-roller system 6 and a second inner-roller system 8, the first inner-roller system 6 and the second inner-roller system 8 are located on the blank Inside 17, the first outer wheel system 5 and the second outer wheel system 9 are located outside the blank 17. The blank 17 is pressed and fixed by the tail top system 16 and the main shaft system 18. The frame 12 is a box-shaped structure, and the left and right ends each The first rack support base 1 and the first servo motor system 2 are installed at one end, and the upper and lower ends are wide linear guide rail substrates;

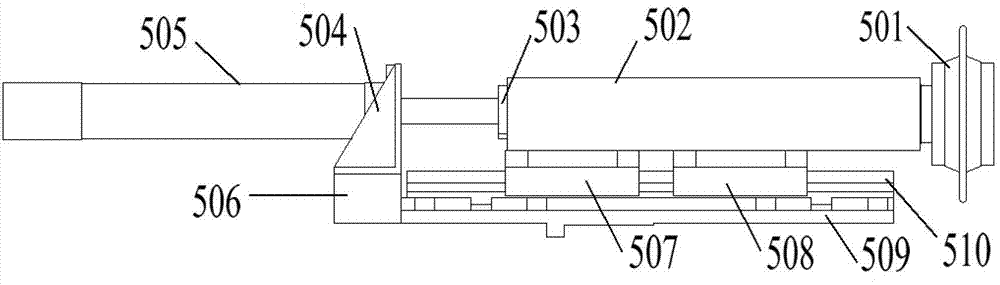

[0029] The first servo motor system 2 is installed in the lower position of the left end of the frame 12 through bolt connection, the first servo motor system 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com