A device and method for molybdenum crucible double-wheel staggered hot-state powerful spinning

A technology of spinning forming and powerful spinning, which is applied in the field of powerful spinning, can solve the problems of reducing the roughness of the inner surface, achieve the effect of improving the quality of the inner surface, reducing the amount of single deformation, and solving the effects of poor working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

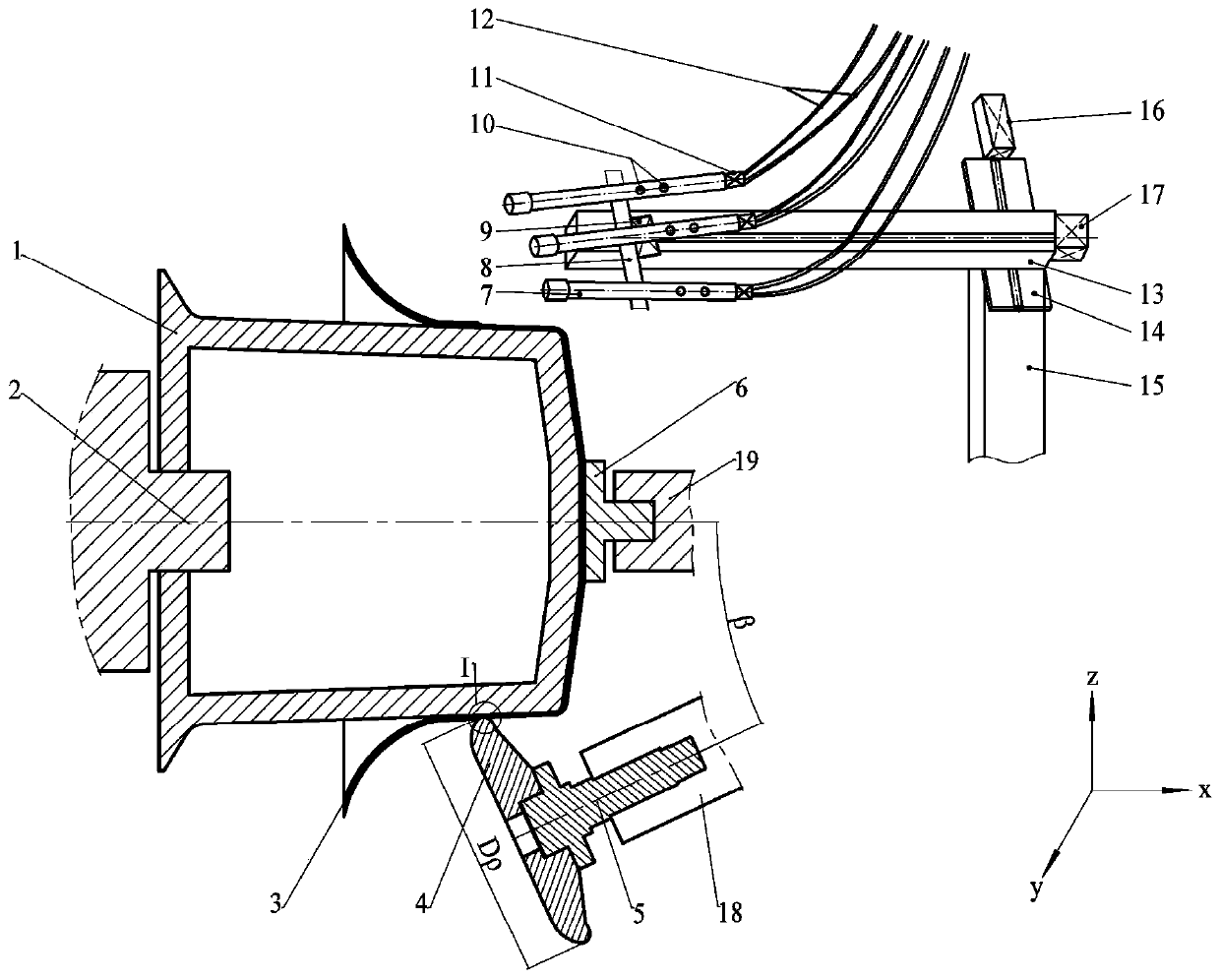

[0095] preparation A spinning molybdenum crucible with a height of 400mm and a bottom thickness of 2.0mm, such as Figure 6-7 shown;

[0096] (1) Using 5CrNiMo alloy as raw material, with Image 6 The inner size of the molybdenum crucible shown is the outer size of the mandrel. After forging, tempering, rough machining, quenching and tempering, and fine machining, the surface roughness of the prepared mandrel reaches Ra0.8μm, and the surface hardness is ≥HRC55. The fit clearance of the press spindle is -0.08mm. After fastening the mandrel on the spinning equipment, the no-load axial runout of the mandrel does not exceed 0.15mm, and the no-load radial runout does not exceed 0.1mm.

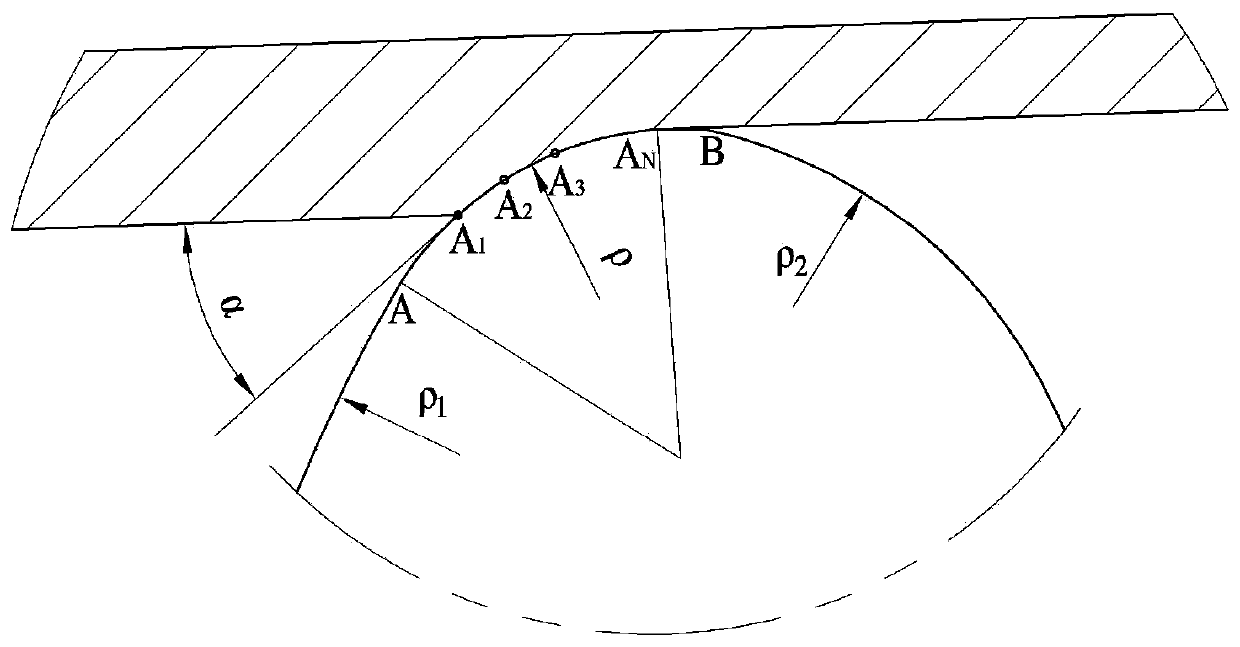

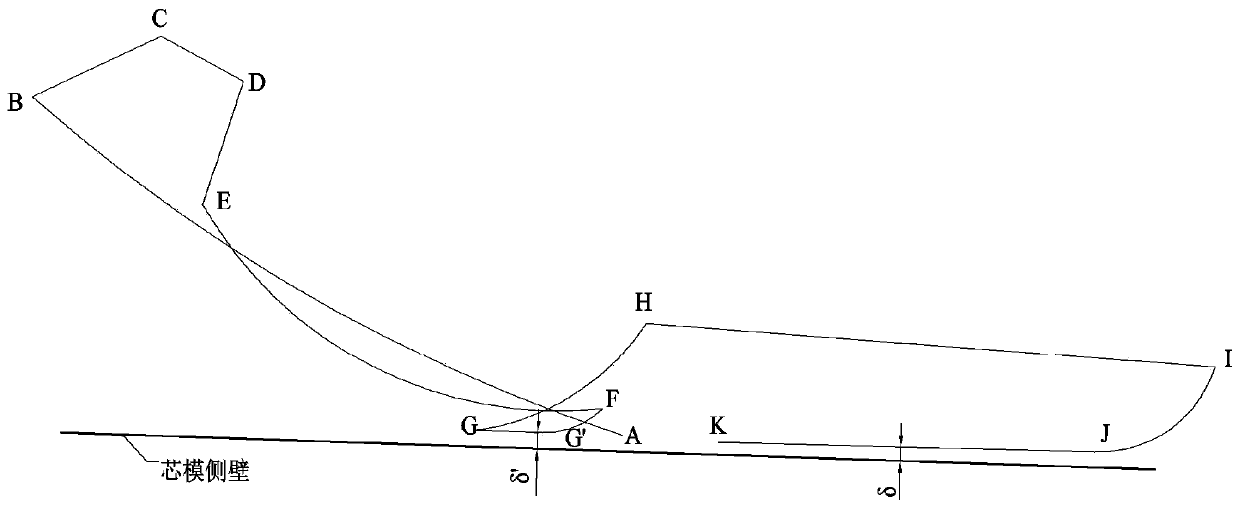

[0097] (2) Using H13 as the raw material, 40°, 30°, 22°, and 5° are respectively used as the spinning forming angles of the front knife, back knife, feed, and molding curves, and then the curves are smoothly connected according to three arcs Design the contours of the front spinner wheel and th...

Embodiment 2

[0108] The prepared diameter is A spinning molybdenum crucible with a height of 469.9mm and a bottom thickness of 4.5mm, such as Figure 8-9 shown;

[0109] Referring to Example 1, the process conditions different from Example 1 and related parameters are shown in Table 1.

[0110] The processing parameter of table 1 embodiment 2 and relevant data

[0111]

Embodiment 3

[0113] preparation A spinning molybdenum crucible with a height of 406.4mm and a bottom thickness of 4.5mm, such as Figure 10-11 As shown, referring to embodiment 1, the process conditions different from embodiment 1 and relevant parameters are as shown in table 2.

[0114] The processing parameter of table 2 embodiment 3 and relevant data

[0115]

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com