Surface processing equipment

A surface processing and equipment technology, applied in metal processing equipment, milling machine equipment, details of milling machine equipment, etc., can solve the problems of poor inner surface processing quality, and achieve the effect of improving processing quality, improving movement stability, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

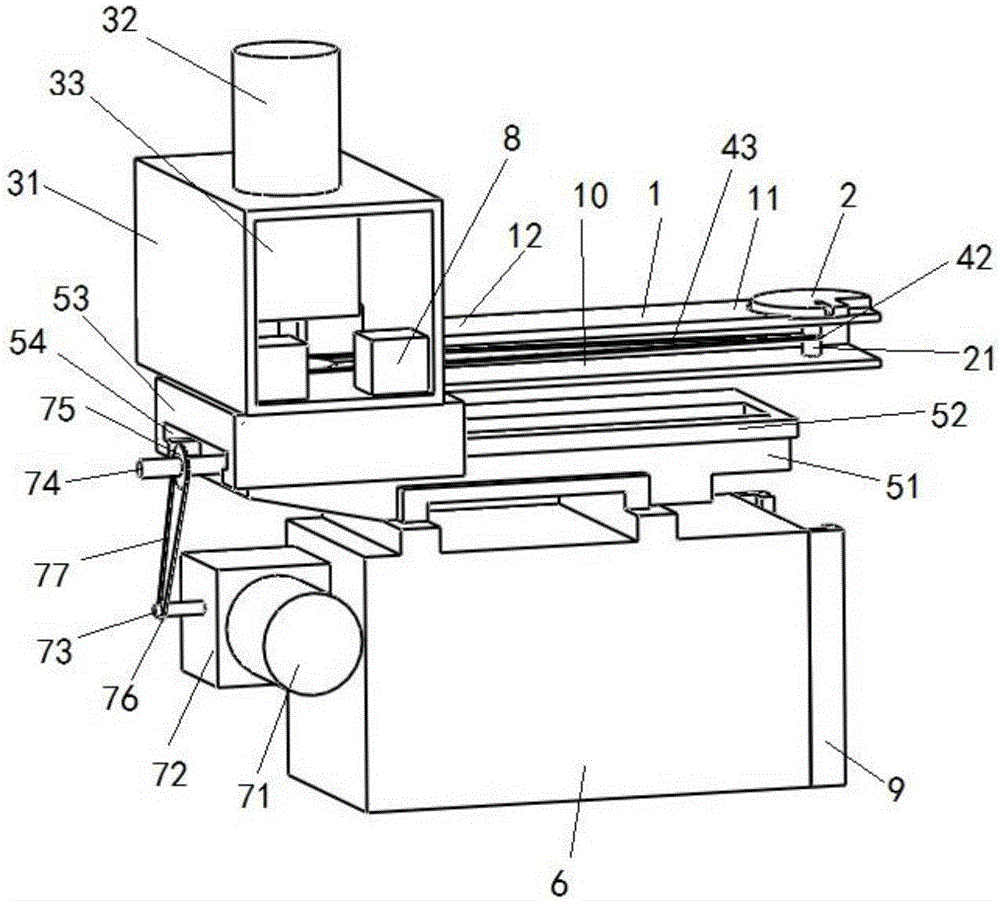

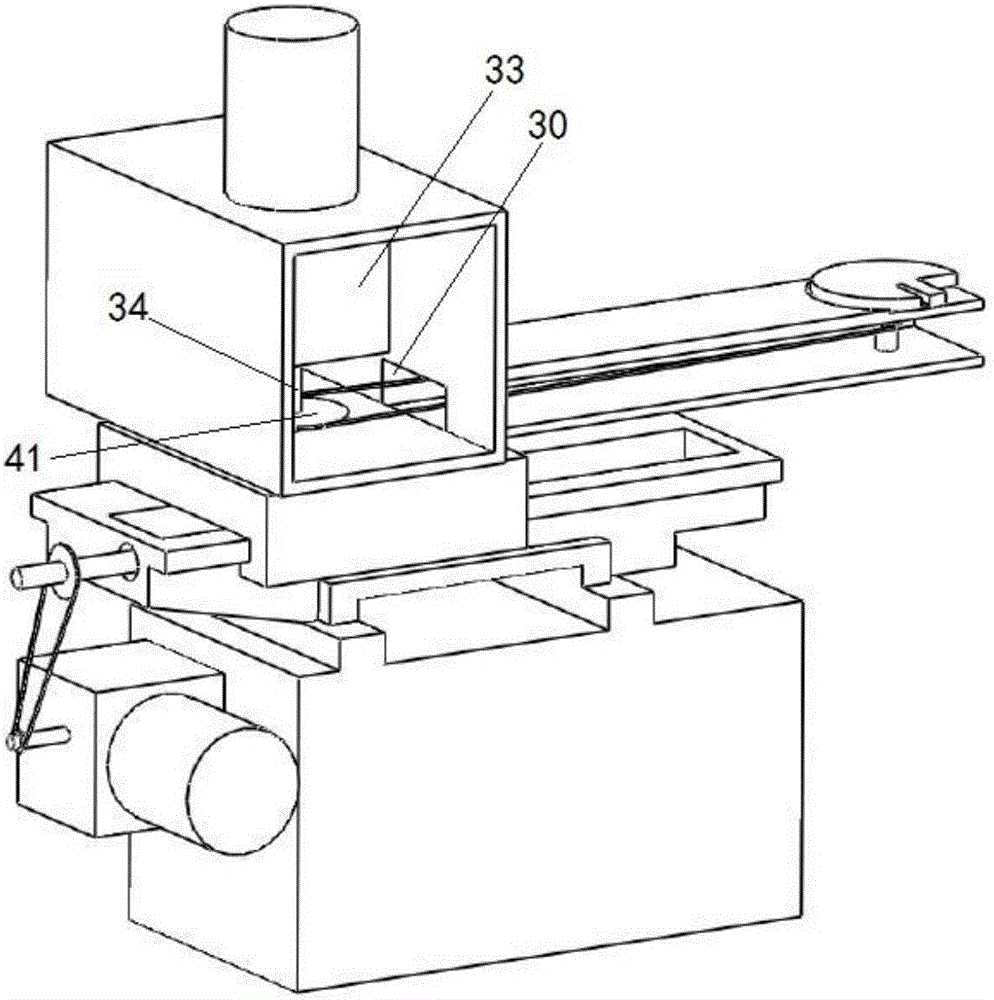

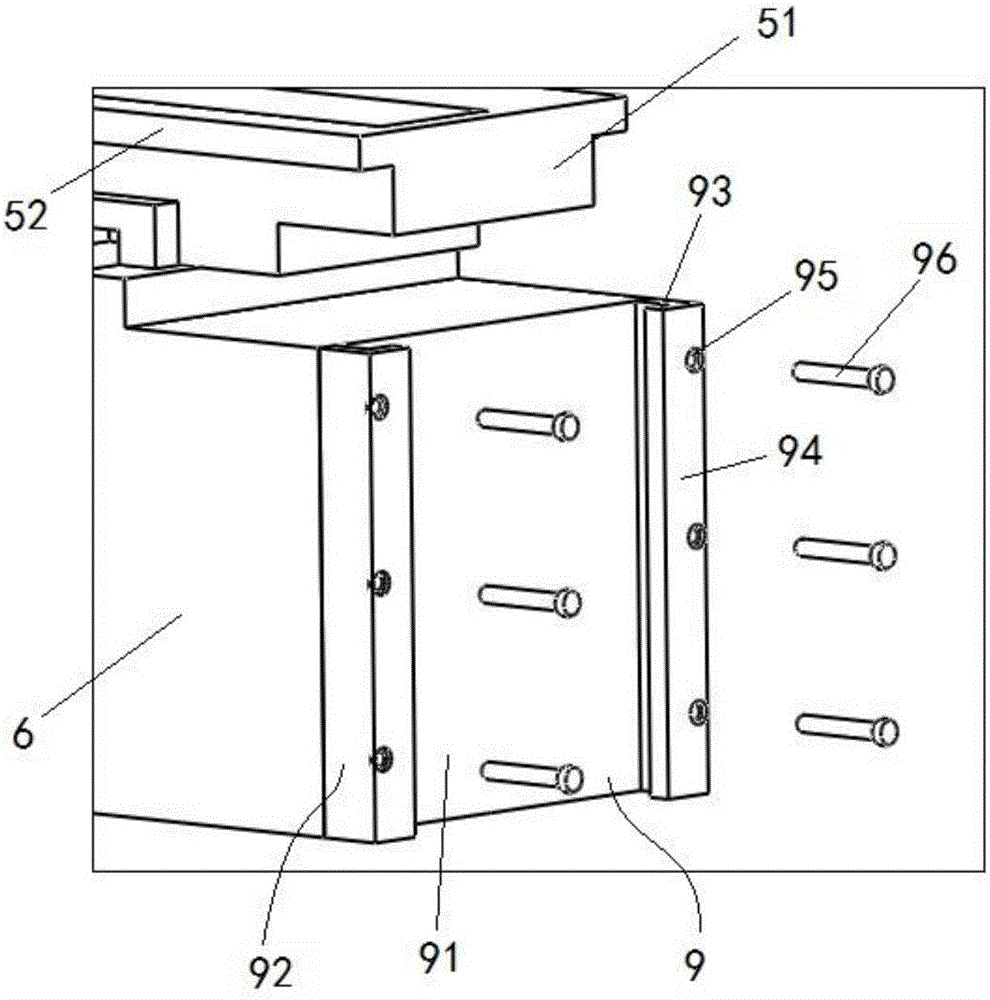

[0052] This embodiment provides a surface processing equipment, such as Figure 1-2As shown, it includes: a cantilever 1, which is a cuboid with a hollow cavity 10, has a first end 11 that can extend into the deep cavity, and a second end 12 opposite to it; It is rotatably installed on the first end 11 for installing a tool; a driving mechanism is fixedly connected with the second end 12 to support the cantilever 1 and is used to drive the tool holder 2 to rotate.

[0053] In the surface processing equipment of this embodiment, a cantilever 1 that can extend into the deep cavity is added between the drive mechanism and the tool holder 2, so that the processing equipment of this embodiment can directly process the inner surface of the deep cavity, which is different from the prior art In comparison, it is no longer necessary to divide the workpiece to be processed, and there is no connection process, so the processing technology is simple, and the processed inner surface is of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com