Spinning milling drilling process for carbon fiber composites

A composite material and gyro-type technology, which is applied to milling machine equipment, manufacturing tools, milling machine equipment details, etc., can solve problems such as service performance impact and delamination, and achieve the improvement of inner surface quality, reduction of burrs, and reduction of exit delamination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

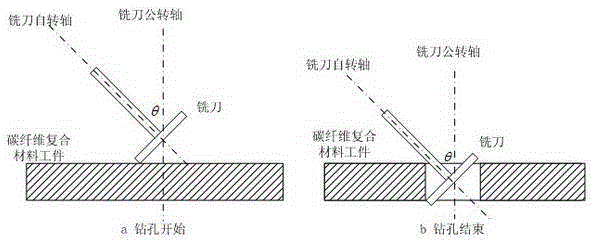

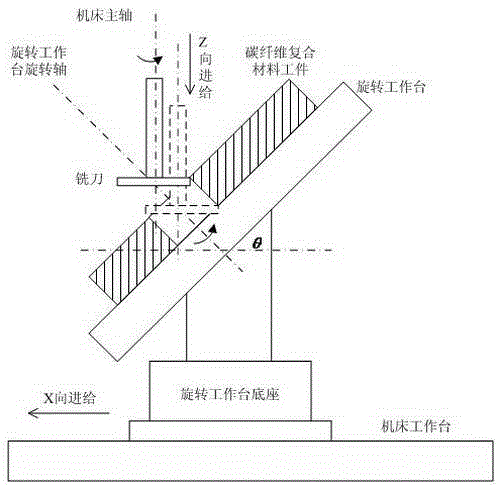

[0012] The present invention proposes to use the "gyro-type" milling and drilling method to drill carbon fiber composite materials, and the "gyro-type" milling and drilling processing principle is as follows: figure 1 shown. While the milling cutter rotates around the rotation axis, it also revolves around the revolution axis, that is, it performs "gyroscopic" motion. The axis of rotation forms an angle with the axis of co-rotation , the included angle It can be adjusted according to the shape of the processed hole. While the milling cutter is performing "gyroscopic" movement, it is fed along the revolution axis towards the surface of the workpiece, so that the "hole" is processed by milling. The biggest advantage of this movement method is that it can greatly reduce the tension on the carbon fiber workpiece at the exit of the "hole", thereby reducing the exit delamination. At the same time, the use of milling instead of traditional drilling can improve the quality of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com